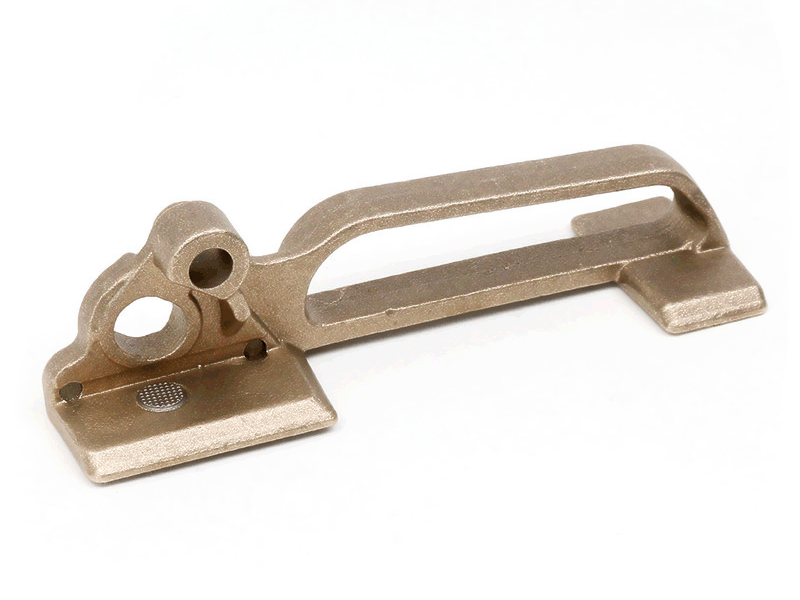

Brass 360 Die Casting Solutions for High-Performance Strapping Machine Components

Introduction

Strapping machines rely on precision-engineered components to maintain long-term mechanical performance. Brass 360 is a premium free-machining copper alloy that offers excellent durability, machinability, and corrosion resistance.

This blog presents a specialized die casting approach using copper-based alloys like Brass 360, along with post-machining and sand blasting techniques that ensure optimal fit, finish, and function for high-load strapping machine applications.

Understanding Brass 360 Material

Brass 360 is a free-machining copper-zinc alloy known for its excellent machinability, corrosion resistance, and structural integrity. Its uniform grain structure and high thermal conductivity make it especially suitable for packaging machinery operating under repetitive mechanical loads and environmental exposure. It also provides a bright, smooth surface finish that benefits both functional and visual requirements in industrial equipment.

Why Choose Copper Die Casting for Brass 360 Strapping Parts

Copper die casting enables the efficient production of dimensionally stable, complex-shaped Brass 360 components. Key advantages include:

Tight Tolerances: Maintains consistent geometry across high-volume production.

Material Utilization: Reduces material waste compared to subtractive machining.

Enhanced Performance: Produces dense, defect-free parts ideal for load-bearing and moving assemblies in strapping machinery.

Key Manufacturing Processes

Copper Die Casting Process

The die casting process begins with specialized Tool and Die Making to ensure accurate molds. Brass 360 is cast under controlled pressure to achieve uniform wall thickness, critical for the structural reliability of dynamic mechanical parts.

Post Machining for Dimensional Control

Post-machining (Post Machining) is essential to fine-tune critical features such as shaft bores, flat seats, and thread details, ensuring compatibility with strapping machine mechanisms. CNC precision guarantees the highest assembly consistency and functional reliability.

Sand Blasting Surface Treatment

Sand Blasting is applied to remove casting oxides, refine surface texture, and improve paint or coating adhesion. For Brass 360 parts, this process also enhances fatigue resistance and provides a clean, professional surface suited for visible machine components.

Quality Assurance for Packaging Machine Applications

All Brass 360 die cast parts undergo rigorous Die castings inspection to ensure conformance with mechanical performance standards, geometric accuracy, and surface quality. Each component is validated for dimensional integrity, ensuring flawless operation in high-cycle environments.

One-Stop Brass Die Casting Solutions Optimized for Packaging Equipment

Brass 360 Copper Die Casting: Our Copper Die Casting process is engineered for high-strength, wear-resistant packaging machine components.

Precision Post-Machining: We provide Post Machining services for enhanced dimensional control, sealing fit, and threaded connections in strapping assemblies.

Industrial-Grade Surface Treatment: Sand Blasting enhances surface finish, cleanliness, and component longevity, critical for durable, professional-grade equipment.

FAQs

What is the typical lead time for custom Brass 360 strapping machine parts?

How does Brass 360 compare to stainless steel in packaging equipment applications?

Can die cast Brass 360 components maintain tight dimensional tolerances?

What is the benefit of sand blasting over polishing for brass parts?

How is surface durability improved through post-machining and blasting?