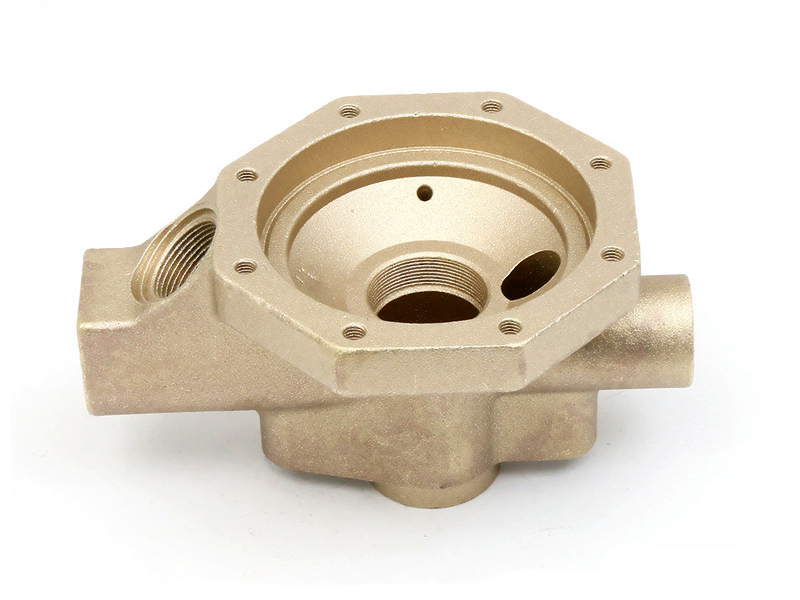

Phosphor Bronze Valve Die Casting Solutions for Pump and Valve Components

Introduction

Phosphor bronze valves play a crucial role in pump and valve systems, providing excellent corrosion resistance and mechanical durability, particularly in marine and harsh operational conditions. Selecting the optimal manufacturing approach significantly impacts the valves' reliability and long-term performance.

This article outlines precise copper die casting solutions specifically designed for phosphor bronze valves, emphasizing essential processes such as professional surface treatments that ensure superior product quality and extended component lifespan.

Understanding Phosphor Bronze Material

Phosphor bronze is widely recognized for its superior strength, corrosion resistance, and excellent wear resistance. Typically containing around 0.5%-11% tin and a small amount of phosphorus, this alloy demonstrates remarkable resilience in harsh environments. In pump and valve components, phosphor bronze offers significant advantages, such as high resistance to seawater corrosion, low friction coefficient, and excellent fatigue endurance, making it ideal for long-term reliability.

Why Choose Copper Die Casting for Phosphor Bronze Valves

Copper die casting is particularly advantageous for manufacturing phosphor bronze valves due to its precision and consistency. This process provides:

High Precision: Achieves intricate geometries and accurate dimensional tolerances critical for valve assemblies.

Enhanced Efficiency: Offers faster production cycles compared to traditional casting methods, effectively meeting high-volume demands.

Superior Mechanical Properties: Ensures dense microstructures and consistent mechanical performance, crucial for reliability in demanding operational environments.

Copper die casting ensures exceptional strength and dimensional stability of phosphor bronze components, meeting stringent quality standards for pump and valve applications.

Key Manufacturing Processes

Copper Die Casting Process

The manufacturing begins with customized tool design, leveraging professional Tool and Die Making services. Expertly engineered molds ensure the high-quality output of phosphor bronze components, while precise control of the casting process maintains component density and structural integrity.

Post Machining Precision

Post-machining (Post Machining) is critical to achieving the required dimensional precision and surface smoothness. CNC machining processes refine the valve dimensions and features, ensuring the tight tolerances necessary for accurate assembly and reliable operation within complex valve systems.

Surface Treatment with Sand Blasting

Surface treatments significantly enhance valve component durability and corrosion resistance. Sand blasting is particularly effective, as it:

Removes surface impurities and casting residues, improving cleanliness and corrosion resistance.

Enhances surface roughness to improve paint and coating adhesion.

Extends the service life by increasing overall corrosion resistance and durability, vital for valves used in aggressive environments.

Quality Assurance for Pump and Valve Components

Quality assurance is integral to our manufacturing processes. We adhere to strict inspection protocols and quality standards to ensure each phosphor bronze valve meets or exceeds industry specifications. Utilizing advanced Die castings inspection techniques, we validate component integrity, dimensional accuracy, and surface finish, guaranteeing exceptional product reliability and performance.

One-Stop Copper Die Casting Solutions Tailored for Your Needs

To fully support our customers' needs, we offer comprehensive copper die casting solutions:

Professional Copper Die Casting: Our Copper Die Casting services ensure high precision and uniform quality, specifically tailored for demanding valve applications within the pump and valve industry.

Precision Post Machining: With expert Post Machining, we guarantee critical dimensions, sealing performance, and accurate assembly to achieve maximum operational reliability.

Advanced Surface Treatment: Our dedicated Sand Blasting treatments significantly improve phosphor bronze valve corrosion resistance, extending their operational life and performance in severe conditions.

FAQs

What is the typical production lead time for copper die cast phosphor bronze valves?

What specific advantages do phosphor bronze valves offer in marine pump and valve applications?

How does copper die casting compare to other traditional casting methods for valve production?

How does post machining influence the operational life of valve components?

Can sand blasting effectively enhance the corrosion resistance of phosphor bronze valves?