Advanced Reverse Engineering for Custom Parts and Design Modifications

Introduction

In modern manufacturing, especially in industries relying on legacy equipment or unique custom parts, original design files are often missing, incomplete, or outdated. Reverse engineering addresses this challenge by transforming a physical object into a precise digital model, enabling part duplication, design upgrades, or process improvements.

At Neway, reverse engineering combines high-resolution 3D scanning, precision measurement, and CAD modeling to deliver production-ready assets. These services are essential for customers in aerospace, automotive, industrial automation, and heavy machinery sectors looking to restore, replicate, or refine critical components.

What Is Reverse Engineering?

Reverse engineering is analyzing a manufactured component to reconstruct its design data. This includes surface geometry, internal features, tolerances, and material characteristics. The goal is to produce a detailed 3D CAD model and associated 2D drawings that can be used for machining, casting, or digital archiving.

This method is valuable in scenarios such as:

Recovering data for obsolete parts with no digital design history

Creating CAD models for tooling or castings from physical references

Digitally capturing competitor or benchmark parts for design comparison

Improving existing parts with enhanced manufacturability or performance

Deliverables typically include parametric 3D CAD files (STEP, IGES, SLDPRT) and manufacturing-ready 2D technical drawings (DWG, DXF, PDF) with dimensional tolerances, thread details, and surface finish callouts.

Reverse Engineering Workflow

Step | Description | Deliverable |

|---|---|---|

3D Scanning or CMM | Non-contact scanning or tactile probing captures external and internal geometry | Mesh file (STL or OBJ), point cloud (XYZ) |

Data Processing | Mesh cleanup, alignment, and feature detection | Cleaned mesh or NURBS surface |

CAD Reconstruction | Solid modeling in parametric CAD tools | Fully editable 3D model |

Drawing Creation | Generation of detailed technical drawings | 2D CAD with GD&T and notes |

Using structured light or laser scanners, the resolution can reach 10–30 microns. CMM probing accuracy is typically ±0.005 mm, suitable for tight-tolerance parts.

Typical Applications

Reverse engineering is used across a wide range of applications, such as:

Legacy component replacement: Recreating parts for outdated machinery or vehicles

Tool and mold reconstruction: Rebuilding casting tools when CAD files are lost

Rapid prototyping: Digitizing physical prototypes for iterative design development

Spare parts manufacturing: Replacing components for which drawings no longer exist

Design optimization: Modifying or improving geometry based on performance data

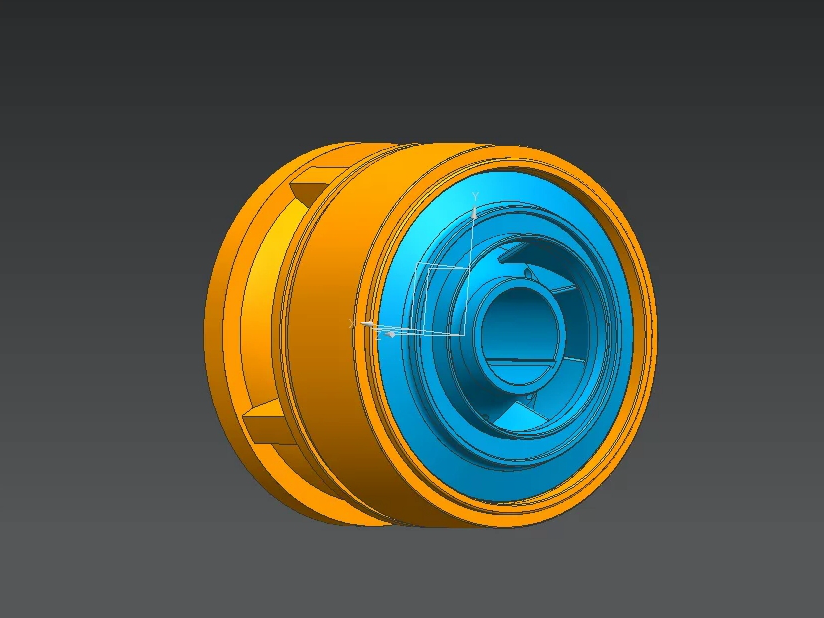

In one example, Neway reverse-engineered a damaged impeller from a marine pump using structured light scanning and CAD surfacing. After adjusting wall thickness and blade angles for better flow, the updated part was successfully machined and outperformed the original by 15% in flow rate efficiency.

Benefits of Reverse Engineering

Attribute | Specification | Impact |

|---|---|---|

Accuracy | Up to ±0.02 mm depending on scanner and part geometry | Ensures reliable replication of fine features |

Speed | Turnaround in 2–7 days depending on part complexity | Reduces downtime for critical part replacement |

Compatibility | Files delivered in STEP, IGES, SLDPRT, DWG, DXF | Seamless integration with CAD/CAM platforms |

Flexibility | Compatible with parts made from metal, plastic, or composites | Supports a wide range of industries and applications |

Customization | Editable models allow geometry improvements or tolerance updates | Ideal for performance enhancements or redesigns |

Our process ensures that all digitized components are modeled to manufacturing standards, including ISO 2768 for general tolerances and ASME Y14.5 for GD&T annotations.

Industries and Use Cases

Reverse engineering is beneficial in the following sectors:

Aerospace: Replacing structural brackets or castings for aircraft with limited documentation

Automotive: Recreating discontinued parts for classic or specialized vehicles

Medical devices: Digitizing ergonomic tools or prosthetics for custom fitting

Energy: Refurbishing valve bodies, turbine blades, or gearbox components in the field

Heavy equipment: Redesigning wear components like bushings, clamps, or couplers for longer service life

These applications often include a combination of scanning, CAD modeling, and CNC production or casting from the reverse-engineered design.

Integration with Manufacturing and Engineering Services

Reverse engineering is most effective when paired with other digital manufacturing solutions. Neway offers:

CNC machining: Machining replacement parts directly from reverse-engineered models

Casting: Using digitized models to recreate tools or molds for die casting

CAD modeling and drafting: Generating full assembly models or component drawings

Design optimization: Improving geometry or material usage for better cost-performance ratios

Rapid prototyping: Validating reverse-engineered parts quickly via 3D printing or urethane casting

We also offer confidential data handling and non-disclosure agreements to protect proprietary information.

Supported Formats and Deliverables

Input | Output |

|---|---|

Physical sample | 3D model (STEP, IGES, STL), 2D drawing (DWG, DXF, PDF) |

Point cloud or STL | Parametric CAD model |

Hand sketch | Modeled and dimensioned digital file |

All files are tested for geometry integrity and manufacturability prior to delivery.

FAQs

What types of parts can be reverse engineered?

How accurate are your 3D scanning and modeling processes?

Can the reverse-engineered model be modified or optimized?

What CAD software do you use to deliver models?

How long does the reverse engineering process typically take?