Affordable and Scalable Bulk Manufacturing for Cost-Effective Solutions

Introduction

In a highly competitive global market, balancing scalability, performance, and cost efficiency is critical. Bulk manufacturing—when implemented with the right engineering and production strategy—offers an optimal path to reducing per-unit cost while maintaining high-quality standards. At Neway, we provide affordable, scalable bulk manufacturing solutions using advanced die casting, CNC machining, and in-house post-processing, optimized for volumes from 10,000 to over 1 million units annually.

What Is Bulk Manufacturing?

Bulk manufacturing refers to large-scale part production with consistent outputs and minimal variation. It typically involves:

Annual volumes ranging from 10,000 to over 5,000,000 parts

Multi-cavity tooling and high-speed automation

Just-in-time (JIT) and blanket order scheduling for efficient delivery

Cost savings up to 30–40% compared to small-batch methods

Industries like automotive, consumer electronics, medical devices, and home appliances rely on bulk production for both OEM and aftermarket components.

Why Choose Bulk Manufacturing?

Advantage | Description |

|---|---|

Lower unit cost | Material and machine utilization improves as volumes scale |

Consistent tolerances | Up to ±0.005 mm with automated inspection and SPC tracking |

High repeatability | Tooling and process stability maintained over 300,000+ cycles |

Flexible delivery | Weekly, monthly, or milestone-based shipments supported globally |

Process traceability | Lot tracking, serialization, and quality documentation per ISO 9001/IATF |

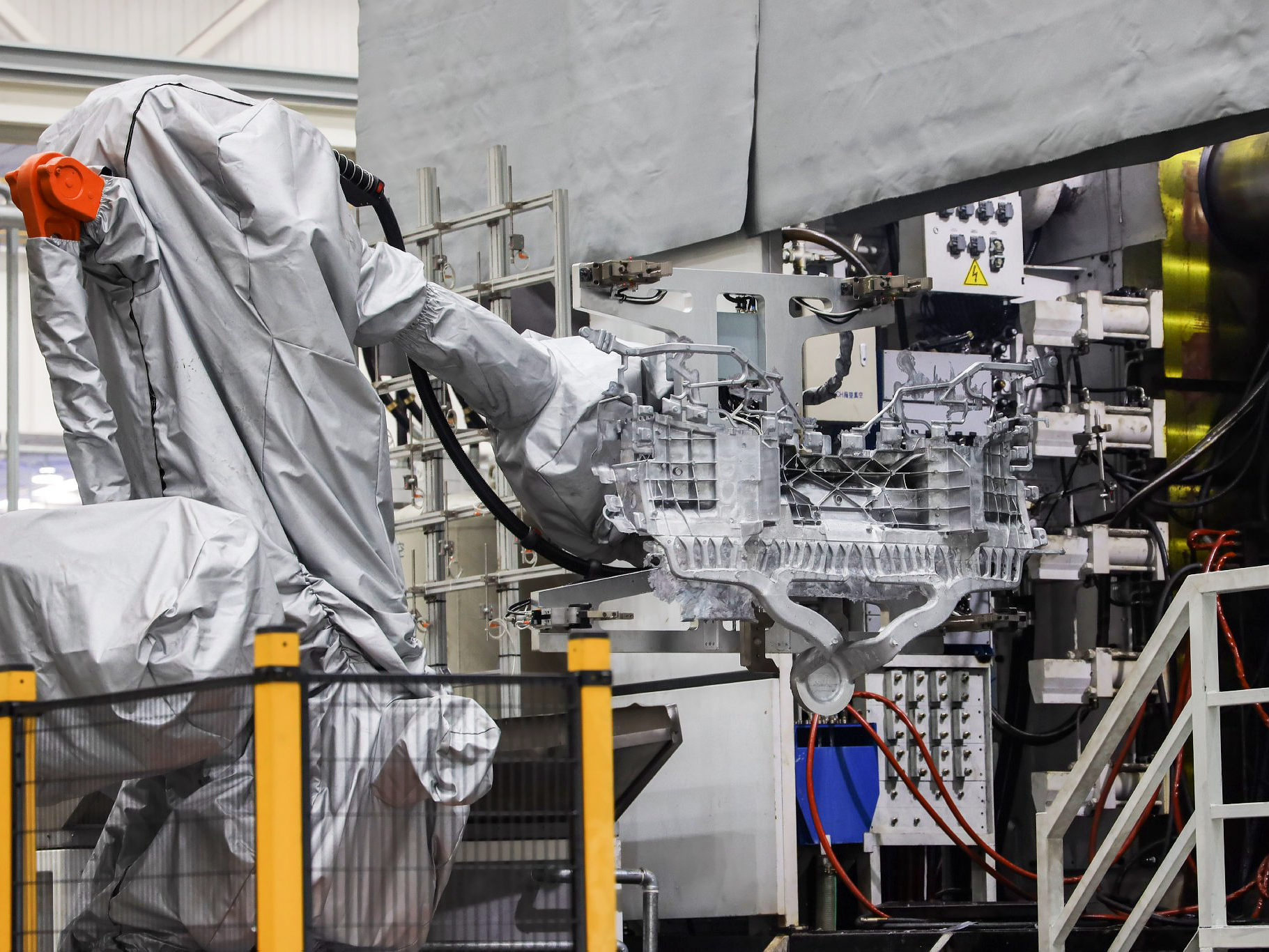

Die Casting for Cost-Effective High Volumes

Die casting is the most economical and precise method for mass-producing metal parts with complex geometries. At Neway, we operate:

Cold chamber machines from 250 to 1,200 tons for aluminum and brass

Hot chamber machines from 150 to 400 tons for zinc alloys

4–6 cavity tools for symmetrical part families

Tool steel dies (H13, S7) for long life—up to 500,000 shots

Supported Alloys

A380 aluminum: Excellent for thermal conductivity (~96 W/m·K) and tensile strength (317 MPa)

Zamak 3: Preferred for its casting precision and dimensional stability

Brass 360: Corrosion-resistant, ideal for plumbing and electrical fittings

CNC Machining for Precision Finishing

CNC machining is used for tight-tolerance features or complex surface geometry. We support:

Tolerance control down to ±0.005 mm for critical features

Multi-axis systems for complex geometries and undercuts

Batch machining volumes up to 50,000/month

Ra 0.8–1.6 µm surface finish achievable on sealing faces and interfaces

We integrate robotic pallet changers, tool monitoring, and SPC systems to maintain consistent output and eliminate human variation.

Scalable Post-Processing and Assembly

High-volume manufacturing includes finishing and integration:

Anodizing: 10–25 µm oxide layer for wear and corrosion resistance

Powder coating: 60–100 µm coating thickness, color-matched

Tumbling and sand blasting for matte or textured finishes

Automated assembly and packaging for retail and OEM distribution

All processes are monitored with in-line and final inspection, including CMM reports, functional testing, and labeling with barcode serialization.

Cost Optimization in High-Volume Programs

Neway ensures cost-effectiveness through:

Tool amortization over long production cycles

Cycle time optimization: Targeting 25–40 seconds per casting shot

Material yield analysis to minimize runner and gate waste (<3% scrap)

Freight consolidation and customs pre-clearance for overseas shipments

Design for Manufacturing (DFM) feedback to reduce machining time and simplify assembly

Case Study: Home Appliance Manufacturer

A client required 1.2 million A413 aluminum control panel covers annually:

Used 4-cavity die tooling, shot every 28 seconds

Applied hard anodizing (20 µm) in black, silver, and champagne

Added CNC-milled boss features and M6 threaded inserts (±0.01 mm)

Delivered in weekly lots of 25,000 parts, fully packaged and labeled

Results:

Unit cost reduction: 22%

Lead time reduction: 35%

Assembly line pass rate: 99.9% (CMM inspection on 1.5% of production)

Why Choose Neway for Bulk Production?

Capability | Specification |

|---|---|

Monthly casting volume | 500,000+ parts (aluminum, zinc, copper alloys) |

Machining precision | ±0.005 mm tolerances on features, Ra 0.8–1.6 µm surfaces |

Tool life durability | Up to 500,000 cycles with tool steel dies |

Automation coverage | From die casting and CNC to finishing and QA |

Global fulfillment | Shipping to 30+ countries with documents and traceability (RoHS, REACH) |

Conclusion

With a partner like Neway, bulk manufacturing becomes a strategic advantage—delivering cost-effective, scalable production without compromising on speed, quality, or service. Whether you need tens of thousands or millions of parts, our facilities and systems are built to deliver.

Contact us today to quote your next mass production program or to request a technical review.

FAQs

What’s the typical per-unit cost advantage for bulk manufacturing at scale?

How long does die casting tooling last at Neway?

Can you support blanket orders with weekly shipping schedules?

What is the achievable surface finish for bulk CNC parts?

Are quality reports and traceability provided for each batch?