Continuous Iterative Design Enhancements to Improve Component Efficiency

Introduction

In today’s fast-paced manufacturing landscape, the ability to iteratively refine designs is a strategic advantage. Continuous iterative design—powered by rapid prototyping, real-time feedback, and data-driven improvements—allows manufacturers to optimize component efficiency across mechanical performance, material usage, and production cost. At Neway, we integrate agile design cycles with CNC machining, 3D printing, and simulation-driven engineering to deliver high-performance, production-ready parts faster and more economically.

What Is Iterative Design in Manufacturing?

Iterative design is a cyclical process that involves:

Prototyping

Testing and feedback

Redesigning

Re-prototyping

This cycle repeats until the component meets predefined performance and manufacturability standards. It replaces static development with a dynamic approach that aligns better with today’s needs for mass customization and short product lifecycles.

Why Iterative Enhancement Improves Efficiency

Each design iteration uncovers new optimization opportunities. For instance:

Reducing material usage with topology optimization algorithms can lower weight without compromising strength

Improving heat dissipation through rib placement and material conductivity adjustments enhances thermal efficiency

Enhancing flow performance in fluid channels or housings by redesigning cross-sections, reducing pressure drop

These refinements can cut unit costs by 10–25%, increase service life by 30%, or reduce thermal load by 15–40%, depending on the application.

Tools That Enable Iterative Refinement

At Neway, our iterative design workflows are supported by:

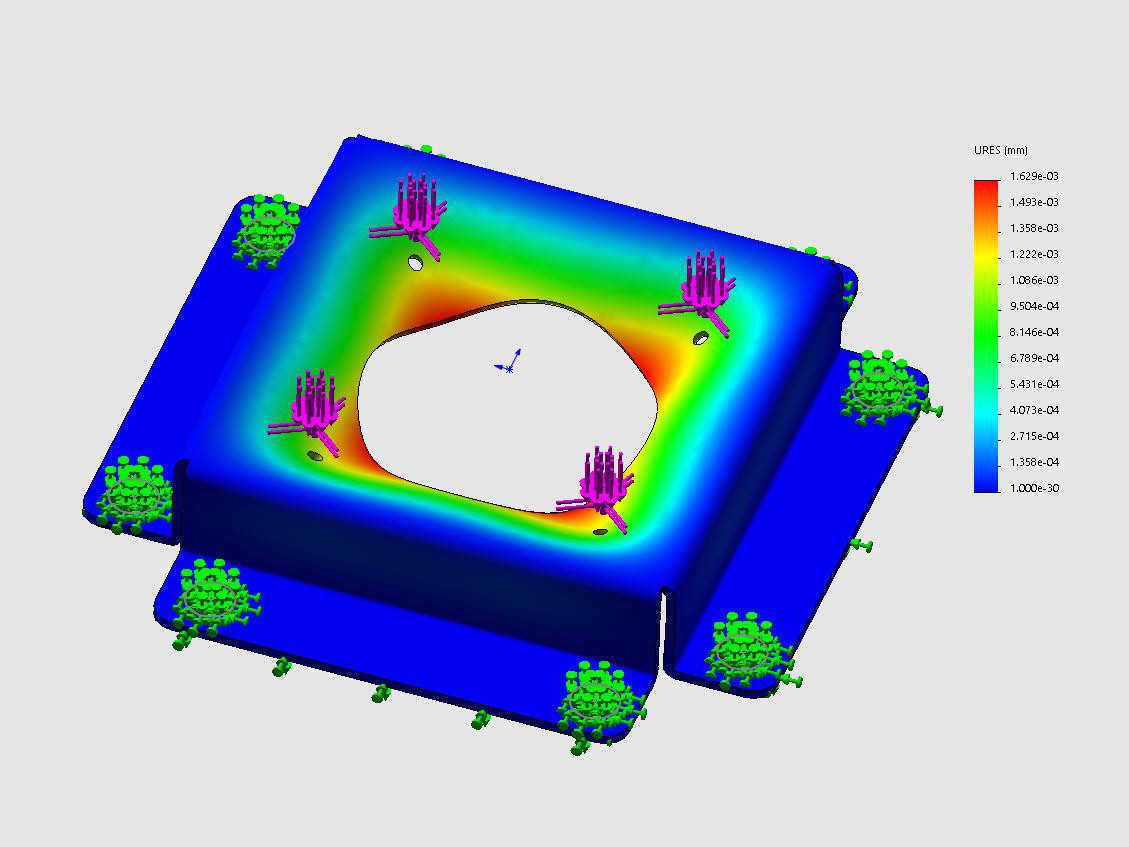

1. CAD & Simulation Software

Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) help identify stress concentrations, deformation under load, or thermal hotspots early. Adjustments can be made before any material is cut or cast.

2. Rapid Prototyping

We use 3D printing (SLA, SLS, FDM) for quick turnarounds (24–72 hours) on form and fit models. These are used for:

Ergonomic assessments

Tolerance stack-up analysis

Early-stage stakeholder feedback

3. CNC Machining for Functional Prototypes

CNC machining delivers production-grade prototypes with ±0.005 mm tolerances, enabling functional validation in final-use materials such as:

A380 aluminum: tensile strength ~317 MPa

C18200 copper: conductivity >300 W/m·K

Engineering plastics like PEEK with tensile strength >100 MPa

4. Feedback Loop Integration

Each trial batch is evaluated for:

Performance under load and thermal conditions

Assembly fit, ease of installation

Production metrics like machining time, toolpath efficiency, and scrap rates

Data is documented and looped back into the CAD model for the next iteration.

Example of Iterative Design in Action: Gear Housing Optimization

A client manufacturing transmission gear housings initially experienced part failure due to thermal distortion and structural fatigue. Through 5 iterative cycles over 6 weeks, we:

Added radial ribs for structural reinforcement

Switched from Zamak 12 to AC4C aluminum for better thermal properties

Modified gating and venting paths for uniform solidification

The final design passed 5 million cycle fatigue tests and reduced casting porosity to under 0.3%.

Post-Iteration Finishing and Verification

Once the design stabilizes, final components undergo post-processing, which may include:

Powder coating or anodizing for corrosion resistance

Post-machining to achieve high-precision fits

CMM inspection for dimensional verification

By ensuring the last prototype iteration meets both design and manufacturing targets, we pave the way for smooth transition into low-volume production or mass production.

Benefits of Continuous Iteration

Benefit | Impact |

|---|---|

Enhanced component efficiency | Higher performance, reduced energy loss, better durability |

Accelerated time-to-market | Faster validation through parallel design and test cycles |

Lower risk | Fewer surprises during mass production |

Cost-effective refinement | Avoids costly changes after tooling or launch |

Conclusion

Continuous iterative design enhancements empower manufacturers to build better products—faster and with greater confidence. By leveraging modern prototyping tools, simulation insights, and responsive production methods, Neway delivers high-efficiency components ready for real-world success.

Let us help you transform your concept into a fully validated, production-optimized part with every iteration.

FAQs

How many iterations are typically needed before finalizing a design?

What is the benefit of using simulation tools in iterative design?

Can iterative prototypes be made using final production materials?

How does continuous iteration reduce development cost?

Is post-machining necessary after each design refinement?