Custom Assembly and Secure Packaging for Ready-to-Use Components

Introduction

Efficient manufacturing extends beyond creating quality parts, including delivering fully assembled, securely packaged components. Neway offers tailored assembly and packaging solutions compliant with international standards like ISTA and ASTM.

Our integrated services streamline logistics, reduce lead times, and ensure your products reach customers safely and ready-to-use, enhancing efficiency and customer satisfaction across various industries.

Why Integrated Assembly and Packaging Matter

In competitive global markets, minimizing the complexity of sourcing, handling, and logistics is essential. Integrated assembly and packaging services provide:

Reduced labor and overhead costs by eliminating in-house post-machining and assembly tasks.

Accelerated lead times by 20–30%, ensuring faster market delivery.

Enhanced product protection, reducing shipping damage by up to 90%.

Consistency and uniformity through standardized assembly processes.

Compliance with international packaging standards (ISTA, ASTM D4169, ISO 11607).

By partnering with a single, reliable supplier for assembly and packaging, manufacturers achieve greater efficiency, lower costs, and higher customer satisfaction.

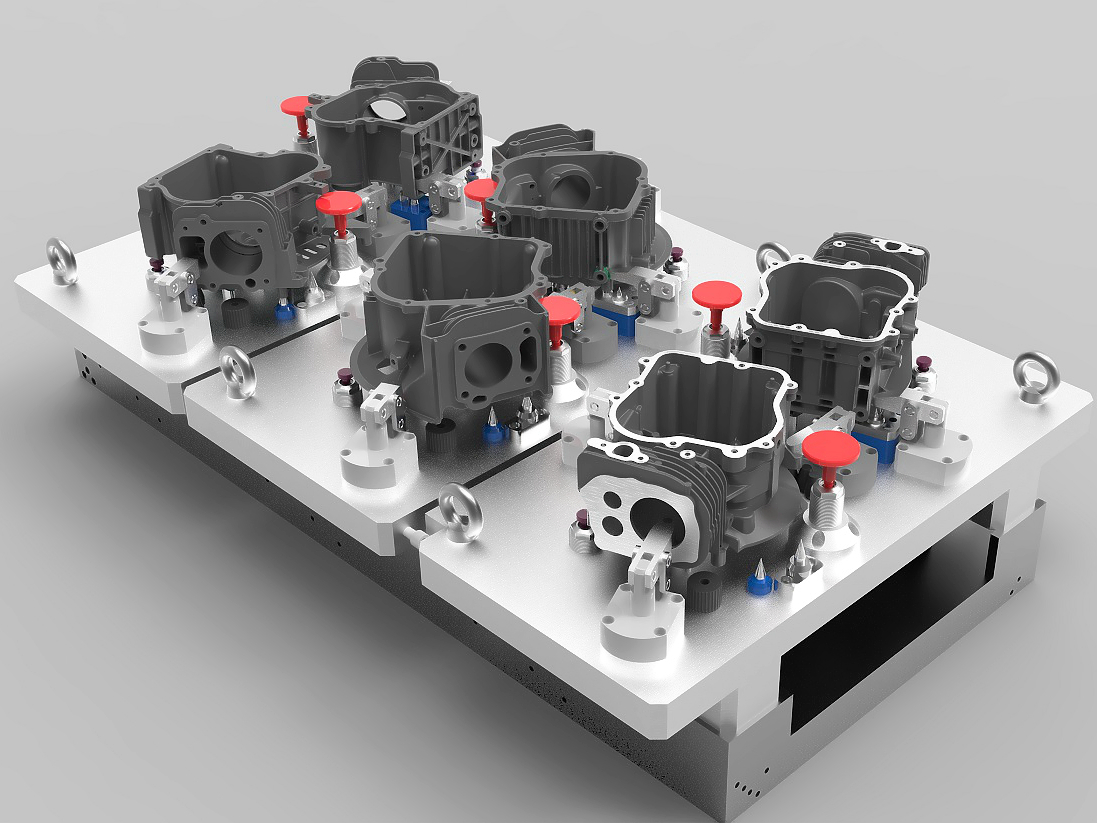

Comprehensive Custom Assembly Solutions

Our custom assembly services include a wide range of operations, tailored specifically to your product specifications:

Mechanical Assembly

Precision insertion of threaded inserts, studs, and fasteners (torque-controlled within ±5% per ISO 6789).

Press-fitting components (tolerance range: ±0.02 mm for critical fits).

Assembly of metal, plastic, and mixed-material components compliant with IPC-A-610 standards.

Electronic and Electromechanical Assembly

Integration of PCB assemblies, sensors, and wiring harnesses following IPC standards.

Electrostatic discharge (ESD) controlled assembly environments (ANSI/ESD S20.20 compliant).

Functional testing and inspection including continuity, insulation, and performance tests (ISO 9001 certified).

Sealing and Gasketing Solutions

Application of sealing materials such as O-rings, gaskets, adhesives, and sealants.

Achieving IP ratings (IP65–IP68) through precise assembly and sealing techniques.

Validation via leak-testing equipment per ASTM F2096 or equivalent standards.

Custom Secure Packaging Options

Neway provides tailored packaging solutions to ensure products remain protected and pristine through storage, transit, and final delivery:

Protective Packaging Solutions

Foam inserts (PE, PU) tailored to specific component geometries for optimal cushioning (ASTM D3574 compliant).

Anti-static packaging materials compliant with IEC 61340-5-1 for electronic components.

Custom corrugated boxes designed and tested to ISTA 3A and ASTM D4169 standards, ensuring durability and impact resistance.

Labeling and Traceability

Serialized labeling and barcoding conforming to industry standards (ANSI MH10.8.1, ISO/IEC 15416).

Custom logos and instructions printed directly onto packaging materials.

Detailed documentation and traceability reports compliant with ISO 9001 and industry-specific standards (RoHS, REACH).

Industry-Leading Quality Assurance

Quality assurance is embedded within our assembly and packaging processes to guarantee consistent and reliable performance:

Assembly process control using Statistical Process Control (SPC) to maintain defect rates below 0.1%.

Final inspections with Coordinate Measuring Machines (CMM) achieving ±0.002 mm measurement accuracy.

Drop testing and vibration testing for packaging compliance per ISTA and ASTM D4169 standards.

Comprehensive first-article inspection (FAI) and Production Part Approval Process (PPAP) documentation available.

Benefits of Choosing Neway for Assembly and Packaging

Benefit | Details and Specifications |

|---|---|

Reduced lead time | 20–30% faster overall delivery through integrated operations |

Cost savings | Elimination of secondary handling reduces overhead costs |

Packaging compliance | ISTA, ASTM D4169, ISO 11607 certified packaging solutions |

Assembly standards | IPC-A-610, ANSI/ESD S20.20, ISO 9001 quality systems compliance |

Global logistics | Documentation and packaging tailored to international shipping requirements |

Case Study: Fully Assembled Automotive Sensor Module

An automotive OEM required fully assembled sensor modules incorporating die-cast aluminum enclosures, threaded inserts, electronic PCBs, and wiring harnesses:

Neway designed a customized assembly line, integrating mechanical and electrical components to IPC-A-610 standards.

Precision torque control (ISO 6789 compliant) ensured consistent assembly performance.

Final products underwent functional tests for electrical continuity and IP67 compliance (water/dust ingress protection).

Packaging utilized customized foam inserts and ISTA-compliant corrugated boxes, reducing transit-related defects by over 90%.

Result: The customer achieved a 25% reduction in total project lead time and significantly streamlined their supply chain logistics.

Conclusion

Integrating custom assembly and secure packaging into your manufacturing workflow offers significant operational, logistical, and cost advantages. At Neway, our expertise ensures your components arrive ready-to-use, consistently meeting and exceeding stringent industry standards.

Choose Neway for fully integrated, reliable, and efficient solutions that enhance your market competitiveness and customer satisfaction.

FAQs

What assembly capabilities and standards are available for precision mechanical and electronic components?

How does integrated assembly and packaging improve overall supply chain efficiency?

Can packaging solutions meet specific international shipping and regulatory requirements?

What quality control and inspection methods are applied during custom assembly and packaging processes?

What measures are taken to ensure secure packaging and minimize damage during transportation?