Fully Automated Production Lines for High-Speed Manufacturing Efficiency

Introduction

In the age of Industry 4.0, fully automated production lines are transforming how manufacturers approach mass production. Automation delivers unparalleled speed, precision, and scalability by integrating robotics, CNC systems, real-time monitoring, and intelligent logistics. At Neway, we engineer and operate fully automated manufacturing lines designed to handle high-volume casting, machining, and post-processing with exceptional efficiency and repeatability.

What Are Fully Automated Production Lines?

A fully automated production line consists of interconnected machines and systems that execute production tasks without manual intervention. These lines typically include:

Automated die casting cells with robotic part handling

CNC machining centers integrated with pallet changers or gantry systems

Inline inspection stations with CMM and vision systems

Conveyor-based transfer systems and robotic assembly

Data-driven control platforms for real-time performance optimization

These systems work harmoniously to reduce downtime, eliminate human error, and maintain consistent output around the clock.

Benefits of Automation in High-Speed Manufacturing

Feature | Benefit |

|---|---|

Continuous operation | 24/7 production with minimal interruptions |

Consistent quality | Robotic control ensures process stability and repeatability |

Higher throughput | Cycle time reductions of 30–60% compared to manual setups |

Real-time monitoring | Smart sensors track every parameter from mold temperature to spindle speed |

Lower per-unit cost | Maximizes output while reducing labor and scrap |

Applications of Fully Automated Lines

Automated lines are most effective in high-volume, repeatable part production environments such as:

Automotive: Transmission housings, engine covers, brackets

Consumer electronics: Connector shells, heat sinks, enclosures

Appliances: Motor housings, frames, panels

Lighting and telecom: LED heat sinks, junction boxes, RF shields

Industrial components: Valve bodies, pump casings, electrical hardware

Automation in Die Casting Production

Neway’s die casting lines are equipped with the latest automation technologies:

Multi-cavity dies to produce several parts per cycle

Automated ladling systems for metal transfer

Robotic extractors with programmable cooling delay

Spray lubrication and mold release cycles

Vision systems for in-mold part verification

We operate horizontal cold chamber and hot chamber machines with clamp forces from 150 to 1,200 tons, supporting annual volumes exceeding 1 million units.

Case Example: Automotive Die Casting Line

For a Tier-1 automotive supplier, Neway deployed an automated line to produce 600,000 gear housings per year using A380 aluminum. The cell included robotic ladling, extraction, trimming, and CNC post-machining, reducing labor costs by 40% and improving first-pass yield to 98.7%.

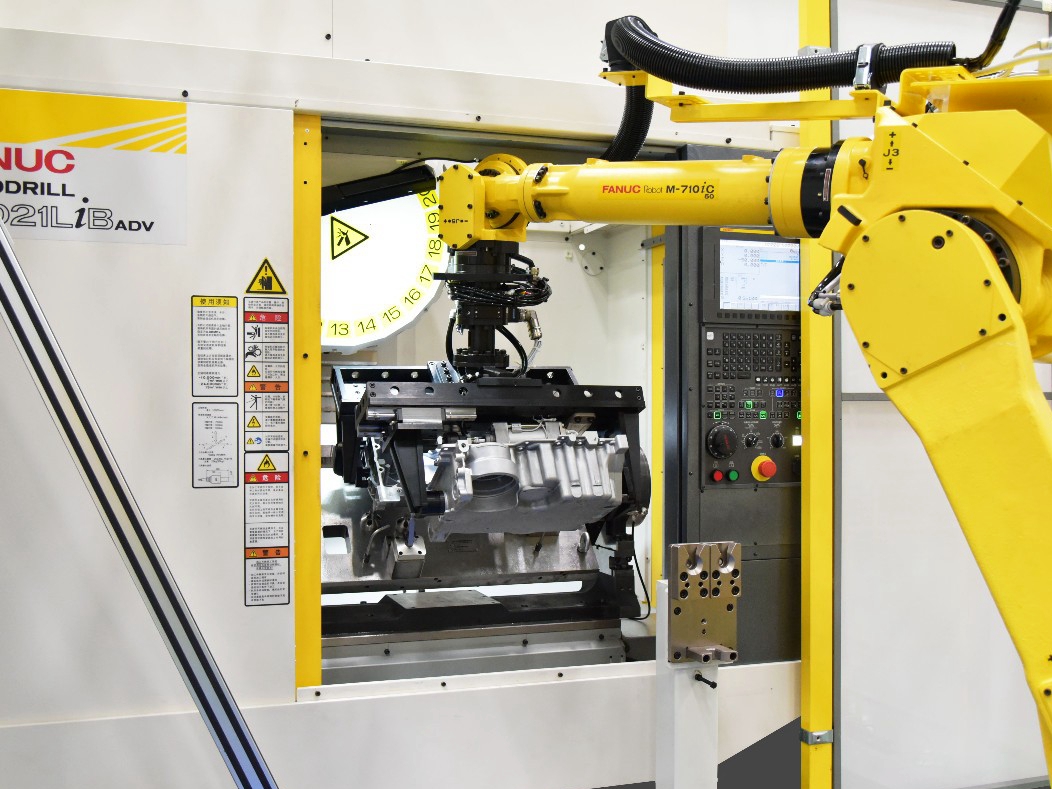

Automation in CNC Machining Operations

We also integrate full automation into our CNC machining lines:

Robotic arm or gantry systems for loading/unloading

Tool monitoring and break detection with automatic changeovers

Zero-point fixtures and pallets for quick indexing

Inline CMM inspection every nth part or batch

Auto deburring and chip handling stations

These allow Neway to machine tens of thousands of castings per month with tolerances as tight as ±0.005 mm and surface finishes down to Ra 0.8 µm.

Post-Processing and Assembly Automation

Fully automated lines extend beyond casting and machining to include finishing and assembly:

Tumbling, sand blasting, and anodizing stations with automatic part handling

Robotic painting and powder coating booths

Optical alignment systems for assembly tasks such as fastener insertion or gasket placement

Final CMM inspection and labeling modules

Data-Driven Manufacturing with Smart Controls

Our fully automated lines are managed via a centralized MES (Manufacturing Execution System), which provides:

Real-time status dashboards (OEE, uptime, cycle time)

SPC data collection for trend analysis

Predictive maintenance alerts

Production tracking with full traceability by part and lot number

This lets us respond instantly to anomalies, prevent downtime, and continuously optimize operations.

Why Choose Neway for Automated Manufacturing?

Capability | Specification |

|---|---|

Cycle time | 15–60 seconds per part depending on geometry and material |

Dimensional tolerance | Up to ±0.005 mm (machining), ±0.10 mm (casting) |

Automation coverage | Die casting, CNC, finishing, inspection, packaging |

System uptime | >95% achieved across production cells |

Throughput capacity | Up to 50,000 parts/month per line |

Conclusion

Fully automated production lines are the backbone of modern high-speed manufacturing. By minimizing manual intervention and maximizing consistency, automation allows companies to scale confidently, delivering high-quality parts faster and more affordably.

At Neway, we design and operate fully automated die casting and machining lines for global OEMs and Tier 1 suppliers. Contact us today to learn how automation can transform your production efficiency.

FAQs

What part volumes justify the investment in a fully automated production line?

Can automation be applied to aluminum, zinc, and copper casting?

How does automated inspection ensure dimensional accuracy?

What cycle times are typical for robotic die casting lines?

Is Neway’s automation scalable for future part variants?