Functional Prototype Testing for Performance, Durability, and Accuracy

Introduction

Functional prototype testing plays a crucial role in validating the performance, structural integrity, and dimensional accuracy of components before mass production. It helps engineers identify potential design flaws, material limitations, and manufacturing constraints early in the development cycle. At Neway, we combine precise CNC machining, rapid prototyping, and advanced testing protocols to ensure every prototype meets rigorous real-world standards.

Why Functional Prototype Testing Matters

Unlike visual or conceptual prototypes, functional prototypes are built to closely simulate the final product in both geometry and material properties. They are used to:

Evaluate mechanical performance under expected service loads

Test tolerance-critical features for assembly compatibility

Analyze thermal, electrical, or chemical behavior of materials

Refine component design before tool investment or certification

Investing in thorough testing at the prototyping stage reduces the risk of failure during field use and shortens time-to-market.

Key Functional Testing Categories

1. Performance Testing

Performance testing ensures that the prototype meets its intended operational criteria. Common methods include:

Load and stress testing: Measures tensile, compressive, and flexural strength. For example, A380 aluminum components are tested for yield strength up to 170 MPa and tensile strength up to 317 MPa.

Thermal testing: Evaluates resistance to temperature fluctuations or heat dissipation. Alloys like C18200 copper are tested for thermal conductivity exceeding 300 W/m·K.

Fluid dynamics and sealing tests: Applied in cases like pump housings and valve bodies to ensure leak-proof performance under pressure.

2. Durability Testing

Durability testing assesses a component’s ability to withstand fatigue, wear, and environmental degradation over time.

Cyclic fatigue tests simulate real-world usage, e.g., over 1 million cycles at variable loads for mechanical parts.

Wear resistance evaluations are crucial for components made from materials like Zamak 5, used in rotating or sliding assemblies.

Environmental exposure tests replicate conditions such as salt spray, humidity, and UV radiation for exterior parts.

3. Dimensional Accuracy and Fit Testing

Dimensional testing ensures parts fall within the specified tolerance range, typically:

±0.005–0.01 mm for CNC-machined prototypes

±0.2–0.5 mm for 3D printed models, depending on the process

Accuracy verification methods include:

CMM (Coordinate Measuring Machine) inspections

Laser scanning and 3D model comparison

Gauge and pin testing for press-fit components

These tests confirm that each prototype aligns with design intent and can be reliably assembled with mating parts.

Technologies Used in Functional Testing

At Neway, our prototyping and machining capabilities are backed by advanced inspection and testing equipment, including:

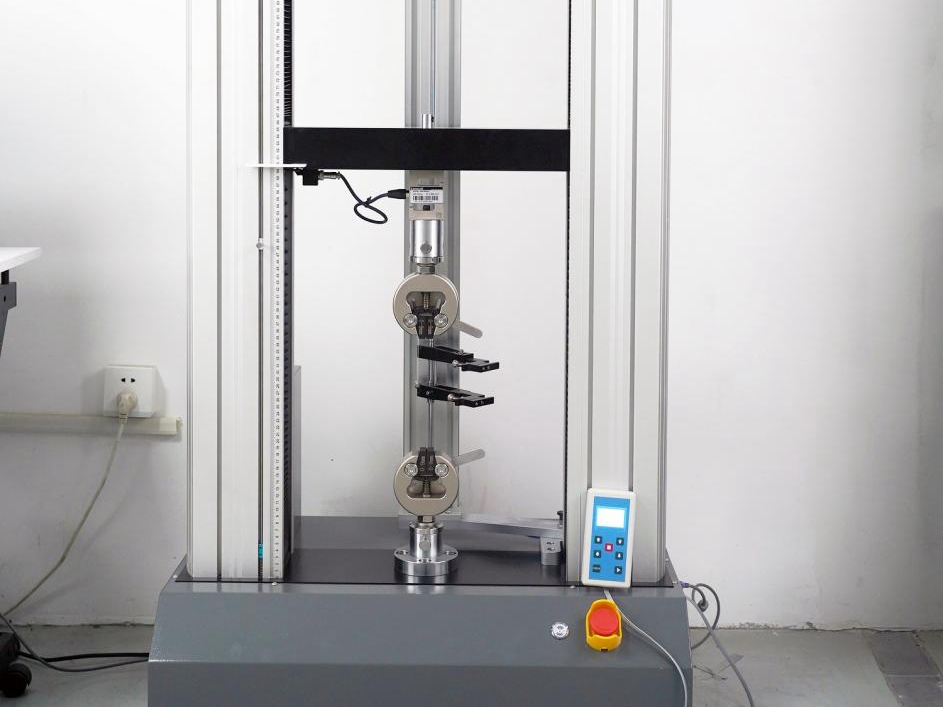

Digital force gauges and load frames for mechanical testing

Thermal chambers for heat and cold shock trials

Surface profilometers for finish analysis (Ra values as fine as 0.8 µm)

High-resolution CMMs for 3D inspection and reverse engineering

We also simulate operating conditions with vibration rigs, salt fog chambers, and endurance fixtures for repetitive motion testing.

Case Applications

Automotive Industry

Functional prototypes of engine mounts and housings made from A380 aluminum are subjected to thermal cycling from -40°C to +125°C, combined with fatigue testing for up to 5 million cycles to simulate years of field use.

Consumer Electronics

Enclosures made from high-conductivity copper or Zamak 3 undergo EMI shielding validation, drop testing from 1.5 meters, and screw thread engagement tests to verify robustness and electromagnetic performance.

Industrial Equipment

Valve prototypes are tested for fluid leakage at pressures up to 10 bar and subjected to 500-hour salt spray tests by ASTM B117 to assess corrosion resistance.

Ensuring Manufacturing Readiness

Functional testing not only verifies design robustness but also highlights manufacturability issues. For instance:

Misaligned features may reveal CNC toolpath or fixturing limitations.

Assembly interference could signal incorrect tolerance stack-ups.

Fracture points during testing may suggest the need for fillet redesign or wall thickness optimization.

Identifying and addressing these concerns during prototyping ensures a smoother transition into low-volume manufacturing or mass production.

Conclusion

Functional prototype testing is a strategic step in modern product development, offering data-driven insights into how a part will perform under real conditions. Manufacturers can avoid costly rework and improve confidence before production by incorporating industry-standard tests for strength, accuracy, and durability.

At Neway, we offer end-to-end prototyping, testing, and production support, ensuring every design is validated, verified, and ready to succeed.

FAQs

What testing methods are used to assess prototype durability?

How does functional testing differ from visual or conceptual prototyping?

What is the standard tolerance for CNC-machined prototypes?

Can prototypes be tested under environmental stress conditions?

How does prototype testing reduce product development risk?