High-Precision 3D CAD Modeling and 2D Drawing Conversion Services

Introduction

Accurate 3D CAD models and 2D technical drawings are the foundation of efficient manufacturing. Whether you're prototyping a new product, preparing for CNC machining, or modernizing legacy drawings, high-precision CAD documentation ensures your project stays on spec and schedule. At Neway, we offer expert 3D CAD modeling and 2D drawing conversion services that bridge design and production, enabling seamless communication between engineering, tooling, and manufacturing teams.

Our CAD specialists support various industries—from automotive to aerospace and industrial equipment—delivering reliable design data for CNC machining, die casting, and rapid prototyping.

What Are CAD Modeling and Drawing Conversion Services?

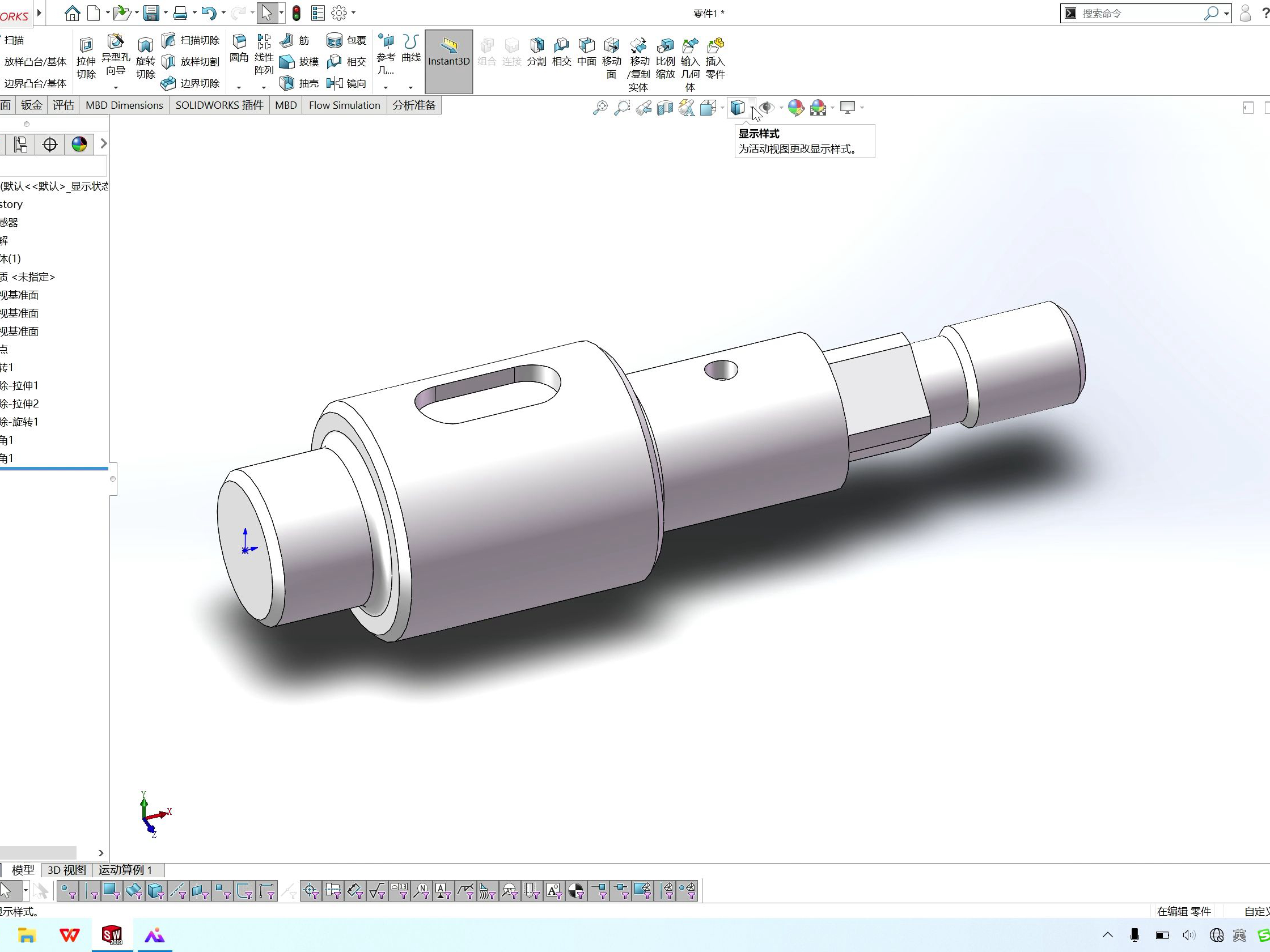

CAD modeling involves creating three-dimensional digital representations of parts, assemblies, or systems using industry-standard software (such as SolidWorks, AutoCAD, CATIA, or Siemens NX). 2D to 3D conversion transforms legacy drawings, hand sketches, or outdated blueprints into fully parametric, editable 3D models.

Key Outputs:

3D CAD Models (STEP, IGES, STL, SLDPRT, X_T)

2D Technical Drawings (DWG, DXF, PDF)

Manufacturing-ready files with tolerances, threads, GD&T, and surface finish callouts

Whether you're starting from a scanned PDF or a physical prototype, our engineering team can generate clean, structured CAD files ready for downstream use.

Benefits of High-Precision CAD Modeling

Benefit | Description | Value for Production |

|---|---|---|

Accuracy and Consistency | Parametric geometry with defined constraints | Eliminates ambiguity and ensures uniformity |

Design for Manufacturability (DFM) | Models include draft angles, fillets, tolerances | Reduces design iterations and machining issues |

Rapid Design Updates | Easily editable and scalable for revisions | Shortens product development cycles |

Simulation and Analysis | Ready for FEA, CFD, or CAM programming | Improves performance and reduces prototyping costs |

Production Documentation | Includes 2D drawings with full dimensional data | Supports CNC machining, inspection, and quality control |

With accurate 3D CAD files, you reduce the risk of rework, avoid interpretation errors, and speed up quotation and production processes—particularly in high-mix, low-volume manufacturing.

Typical Applications and Use Cases

Our CAD modeling and conversion services support a broad range of customer needs, including:

Reverse Engineering: Convert physical parts into digital models for modification or reproduction

Legacy Drawing Modernization: Transform paper blueprints into editable CAD formats

Prototyping: Build accurate 3D models for 3D printing or low-volume production

Manufacturing Prep: Generate machine-ready files for multi-axis machining, die casting, or injection molding

Assembly Modeling: Design entire mechanical systems with full BOM and motion simulation

We support both part-level and complex multi-component assemblies with full geometric dimensioning and tolerancing (GD&T).

Supported Formats and Software

We work with industry-standard formats to ensure compatibility across platforms:

Input Formats | Output Formats |

|---|---|

PDF, DWG, DXF, STL, Sketch | STEP, IGES, SLDPRT, Parasolid, STL, DWG, DXF, PDF |

CAD systems we support include:

SolidWorks

AutoCAD

Fusion 360

CATIA

Siemens NX

PTC Creo

Rhino 3D

We also accept scanned documents, hand sketches, or physical samples with dimensions for full reverse modeling.

Quality Assurance and Engineering Standards

All models and drawings produced by Neway follow engineering best practices and international standards, including:

ISO 2768 for dimensional tolerances

ASME Y14.5 for GD&T

DIN and ANSI standards for threads, fits, and finishes

Before delivery, each CAD model is validated for accuracy, checked against input specifications, and reviewed by senior mechanical engineers to ensure manufacturing readiness.

FAQs

What is the typical turnaround time for a 2D to 3D CAD conversion?

Can you work from scanned blueprints or hand-drawn sketches?

What tolerances and annotations can be added to CAD models?

Are the generated CAD files compatible with CNC and CAM software?

Do you provide NDA protection for confidential drawings and prototypes?