Large-Scale Die Casting and CNC Machining for Mass Production

Introduction

The ability to produce consistent, high-precision parts at scale is critical for high-volume manufacturing. Large-scale die casting and CNC machining offer the ideal combination of speed, dimensional accuracy, and cost-efficiency for mass production of complex metal components. At Neway, we specialize in end-to-end die casting and CNC machining solutions tailored for industries requiring tens of thousands to millions of parts annually, with built-in quality assurance and scalable logistics.

Why Use Die Casting for Mass Production?

Die casting is one of the most efficient processes for producing high volumes of complex metal parts with excellent surface finish and minimal post-processing.

Key Benefits of Die Casting in Mass Production

Benefit | Description |

|---|---|

High Repeatability | Dimensional tolerances of ±0.10 mm or better for consistent parts |

Fast Cycle Times | Up to 4–6 shots per minute depending on mold and part complexity |

Material Efficiency | Minimal scrap and near-net-shape parts reduce raw material waste |

Surface Quality | As-cast surface finish down to Ra 3.2 µm, minimizing secondary processing |

High-Volume Capability | Optimized for batch sizes from 10,000 to over 1,000,000 units annually |

Die Casting Alloys for Scalable Production

Neway supports a full range of casting materials engineered for specific performance requirements:

Aluminum Alloys

A380: The industry standard for its strength-to-weight ratio and fluidity

A360: Offers superior corrosion resistance and ductility

AC4C: Excellent for thermal applications with conductivity up to 120 W/m·K

Zinc Alloys

Zamak 3: Best for tight tolerances and dimensional stability

Zamak 5: Offers better mechanical strength

ZA-8: Ideal for precision gears and small castings

Copper Alloys

Brass 360 and C18200 copper: Used in electrical, plumbing, and heat transfer components for their excellent conductivity and corrosion resistance

CNC Machining for High-Precision Post Processing

While die casting provides the base geometry, CNC machining is essential for achieving critical tolerances, surface finishes, and custom features.

Mass Production CNC Capabilities

Tolerance control up to ±0.005 mm

Surface finishes down to Ra 0.8 µm

Multi-axis machining for complex features

Batch-compatible automation for 24/7 operation

Neway operates CNC lines dedicated to high-throughput machining of die cast parts, with integrated post-machining and in-line metrology systems.

Tooling and Automation Integration

Efficient mass production begins with robust tooling and automation:

H13 and S7 steel tooling for mold life exceeding 500,000 cycles

Multi-cavity dies for simultaneous part production

Automated loading/unloading systems for CNC machining lines

Robotic deburring and part handling for consistent post-processing

Integrated CMM inspection for real-time dimensional validation

These systems ensure consistent part quality and production throughput across high-volume programs.

Applications for Large-Scale Die Casting and CNC Machining

Automotive: Transmission housings, brackets, and engine components

Consumer Electronics: Enclosures, heat sinks, and internal structures

Appliances: Structural frames, motor covers, and panel hardware

Telecom & Energy: Electrical connectors, RF shielding casings, and heat dissipation components

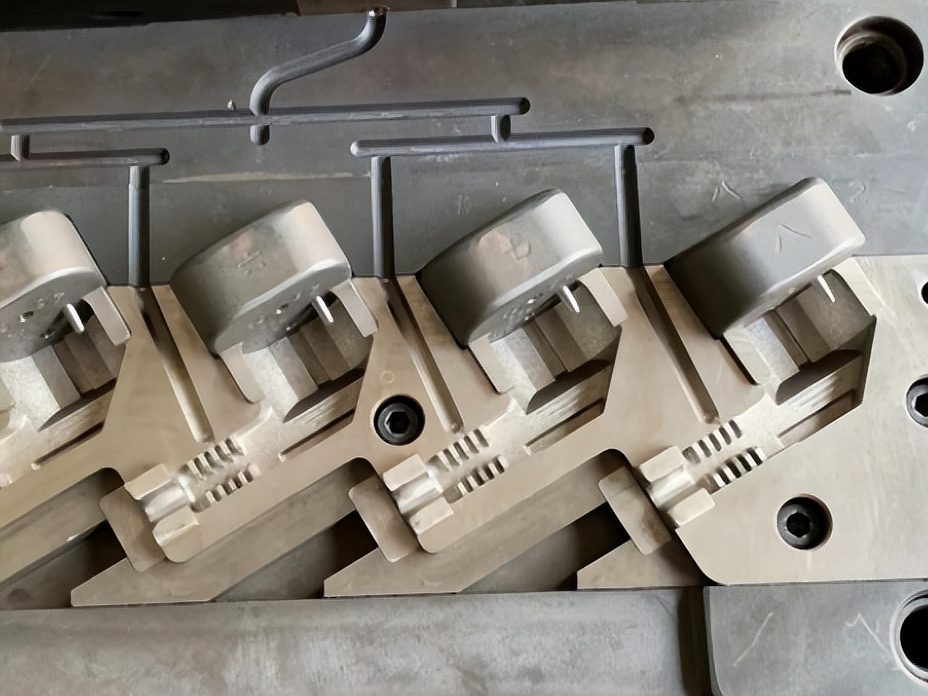

Case Study: Mass-Produced A380 Heat Sink Housings

A telecommunications OEM required 250,000 die-cast heat sink housings annually. We designed a four-cavity tool using A380 aluminum, integrated CNC finish machining, and applied tumbling and black anodizing. The customer received weekly shipments with 100% CMM-inspected batches, supporting uninterrupted assembly operations across multiple sites.

Quality Assurance and Supply Chain Support

Neway maintains strict process controls and documentation for mass production orders:

SPC and PPAP documentation for automotive and aerospace compliance

Full traceability from raw material to finished component

On-site QA team for dimensional inspection, pressure testing, and finish checks

Inventory programs including JIT delivery and consignment for global customers

Conclusion

Large-scale die casting and CNC machining are the backbone of modern mass production. With the right tools, automation, and engineering expertise, manufacturers can produce complex, high-performance parts at scale without sacrificing speed or quality.

At Neway, we deliver world-class mass production services for die cast and machined parts—on time, on spec, and on budget.

FAQs

What’s the minimum and maximum annual volume Neway supports for die cast mass production?

What tolerance levels are achievable with CNC post-machining after casting?

How does Neway ensure consistent quality in high-volume programs?

Can large-scale casting be paired with surface finishing and assembly?

What industries benefit most from mass production CNC and die casting?