Microstructure Integrity: Metallographic Analysis for Defect-Free Metal Casting

Introduction

Ensuring the microstructural integrity of metal castings is crucial to preventing defects and guaranteeing long-term reliability. At Neway, we employ comprehensive metallographic analysis to examine grain structure, phase distribution, and defect presence, allowing precise control over casting quality. Our rigorous evaluations enable defect-free components, ideal for demanding industries such as automotive, aerospace, electronics, and industrial manufacturing.

Importance of Metallographic Analysis

Metallographic analysis is essential for verifying microstructural quality, significantly influencing a casting’s mechanical properties, durability, and overall performance. By performing detailed microscopic evaluations, manufacturers can:

Identify and mitigate common defects (porosity, inclusions, shrinkage, and cracks).

Ensure compliance with international quality standards (ASTM, ISO, SAE).

Verify proper alloy phase formation and grain size control.

Optimize heat treatment processes, maximizing mechanical properties.

Provide reliable documentation and traceability for quality assurance and customer confidence.

Regular microstructural analysis significantly enhances product consistency, reduces failure risks, and ensures predictable casting performance.

Key Components of Microstructural Examination

At Neway, we utilize several standardized metallographic techniques to thoroughly inspect metal castings:

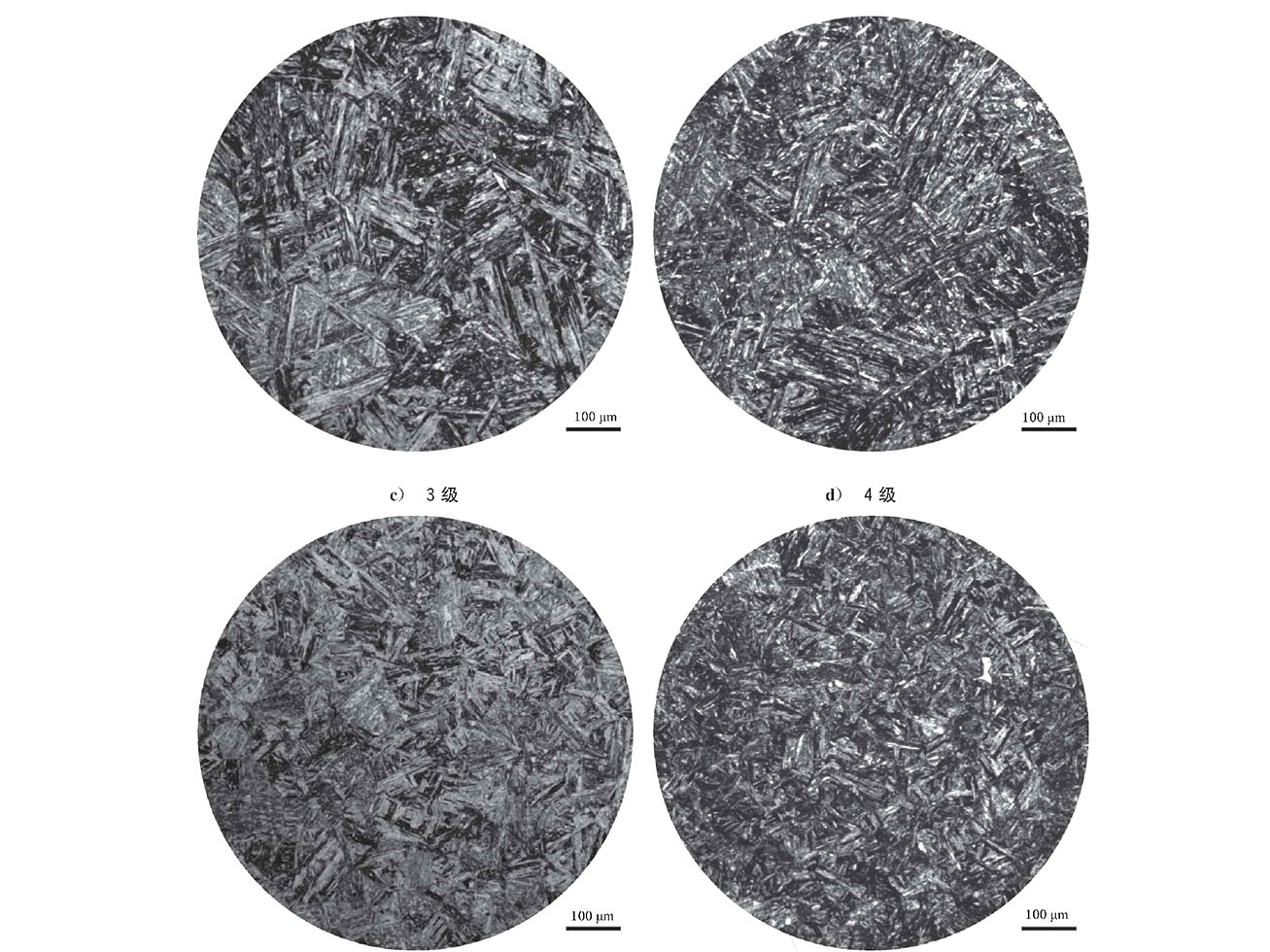

Grain Size Analysis (ASTM E112)

Grain size significantly influences material strength, ductility, and fatigue resistance. Metallographic examination accurately measures grain size, typically ensuring aluminum alloys like A356 and A380 maintain grain sizes within ASTM E112 standard (usually ASTM grain size numbers 4 to 7 for optimal mechanical properties).

Phase Identification and Distribution (ASTM E407)

Phase distribution critically impacts alloy characteristics like strength, toughness, and corrosion resistance. Using chemical etchants (ASTM E407 standard), metallography reveals phases clearly. For example:

Aluminum-silicon phases in alloys such as AlSi12.

Zinc-rich and aluminum-rich phases in zinc alloys like Zamak 3 and ZA-8.

Copper-zinc phases in brass alloys (Brass 360) or nickel-rich phases in copper-nickel alloys (CuNi10Fe1, CuNi30Fe1).

Defect Detection and Analysis (ASTM E3)

Metallography effectively identifies internal casting defects:

Porosity: Internal voids detected clearly at magnifications up to 500x.

Inclusions: Foreign particles clearly visible, enabling source identification and elimination.

Shrinkage cavities: Identified through precise microstructural examination, ensuring corrective measures in future castings.

Techniques in Metallographic Analysis

Neway’s advanced laboratory employs state-of-the-art techniques for comprehensive metallographic evaluation:

Sample Preparation (ASTM E3): Precise cutting, grinding, polishing, and etching processes to ensure clear, artifact-free microstructures.

Optical Microscopy: High-resolution microscopes (up to 1000x magnification), clearly revealing grain boundaries, defects, and phase details.

Scanning Electron Microscopy (SEM): Advanced SEM techniques for detailed examination of microstructures at magnifications up to 100,000x, identifying fine precipitates and micro-defects.

Digital Image Analysis: Computer-assisted grain size, phase fraction, and porosity measurements for enhanced accuracy and reproducibility.

Compliance with International Standards

Our metallographic examinations comply strictly with international industry standards:

Testing Method | Relevant Standards |

|---|---|

Grain Size Analysis | ASTM E112, ISO 643 |

Sample Preparation | ASTM E3 |

Phase Analysis | ASTM E407 |

Defect Detection | ASTM E3, ASTM E45 (inclusions) |

General Quality Assurance | ISO 9001, SAE, AS9100 |

Meeting these rigorous standards ensures our castings consistently deliver defect-free, reliable performance suitable for high-demand industries.

Benefits of Rigorous Metallographic Analysis

Robust metallographic analysis provides several significant advantages:

Enhanced mechanical properties: Precise grain control significantly improves strength and ductility.

Reduced manufacturing defects: Early identification and mitigation of defects reduce scrap rates by up to 50%.

Consistent quality: Maintaining stringent microstructural standards results in reliable, reproducible casting quality.

Long-term durability: Optimized microstructures significantly enhance casting lifespan, even under harsh operational conditions.

Regulatory compliance: Reliable documentation and traceability help meet stringent industry and customer requirements (e.g., RoHS, REACH compliance).

Case Study: Aerospace Aluminum Casting Quality Assurance

An aerospace component manufacturer required microstructural validation of aluminum castings (AC7A):

Grain size analysis confirmed ASTM grain sizes between 5 and 7, ensuring optimal strength and fatigue resistance.

Phase analysis identified uniform aluminum-silicon phase distribution, enhancing mechanical consistency.

Defect analysis via optical and SEM microscopy verified porosity below acceptable aerospace industry limits (<0.5%).

Result: The manufacturer achieved full compliance with aerospace specifications, significantly increasing reliability, safety, and customer satisfaction.

Why Choose Neway for Metallographic Analysis?

Advantage | Specification and Details |

|---|---|

Advanced Lab Capabilities | Optical microscopy, SEM, digital image analysis |

International Standards | Full compliance with ASTM, ISO, SAE, and AS9100 standards |

Material Expertise | Aluminum, zinc, copper alloys, steel alloys |

Accurate Reporting | Detailed, certified reports and documentation |

Reliable Results | Consistent, reproducible analyses with proven accuracy |

Conclusion

Metallographic analysis is critical for ensuring defect-free metal castings with optimal microstructural integrity. At Neway, we deliver rigorous microstructural evaluations, maintaining strict standards and ensuring our customers receive reliable, high-performance metal components.

Partner with Neway for comprehensive metallographic analysis, safeguarding your products’ long-term performance and reliability.

FAQs

Why is metallographic analysis crucial for metal castings?

Which defects can be detected through metallographic analysis?

What international standards govern metallographic testing methods?

How does grain size affect the mechanical properties of castings?

What are the typical metallographic tests conducted on aluminum and zinc alloys?