Optimized Component Designs to Enhance Manufacturability and Efficiency

Introduction

Design optimization is crucial in transforming great product concepts into efficient, cost-effective, and high-performing manufactured components. Whether you're creating parts for CNC machining, die casting, or rapid prototyping, small changes in geometry, material selection, or feature layout can significantly improve cycle time, material usage, and quality.

At Neway, we provide design optimization services tailored to enhance manufacturability, reduce production complexity, and support scalable manufacturing across various industries, including automotive, electronics, industrial equipment, and consumer products.

What Is Design Optimization for Manufacturability?

Design for Manufacturability (DFM) is the engineering practice of refining part geometry, tolerances, and features to simplify manufacturing while maintaining or improving functionality. It ensures components can be produced using available manufacturing processes with minimal risk of errors, rework, or inefficiency.

Key Goals of Design Optimization:

Reduce production time and setup costs

Minimize tool paths and machining complexity

Eliminate unnecessary features or tight tolerances

Improve part strength and performance

Enhance surface finish and assembly compatibility

Engineers can predict and resolve design challenges through advanced CAD tools and simulation before physical production begins.

Design Optimization Techniques We Use

Technique | Description | Benefit |

|---|---|---|

Feature Simplification | Eliminating undercuts, thin walls, deep pockets | Reduces tool wear and CNC cycle time |

Tolerance Analysis | Assigning realistic dimensional tolerances | Avoids costly precision machining when unnecessary |

Material Optimization | Selecting alloys for cost, machinability, and strength | Improves performance and lowers raw material costs |

Part Consolidation | Combining multiple parts into one | Minimizes fasteners and reduces assembly time |

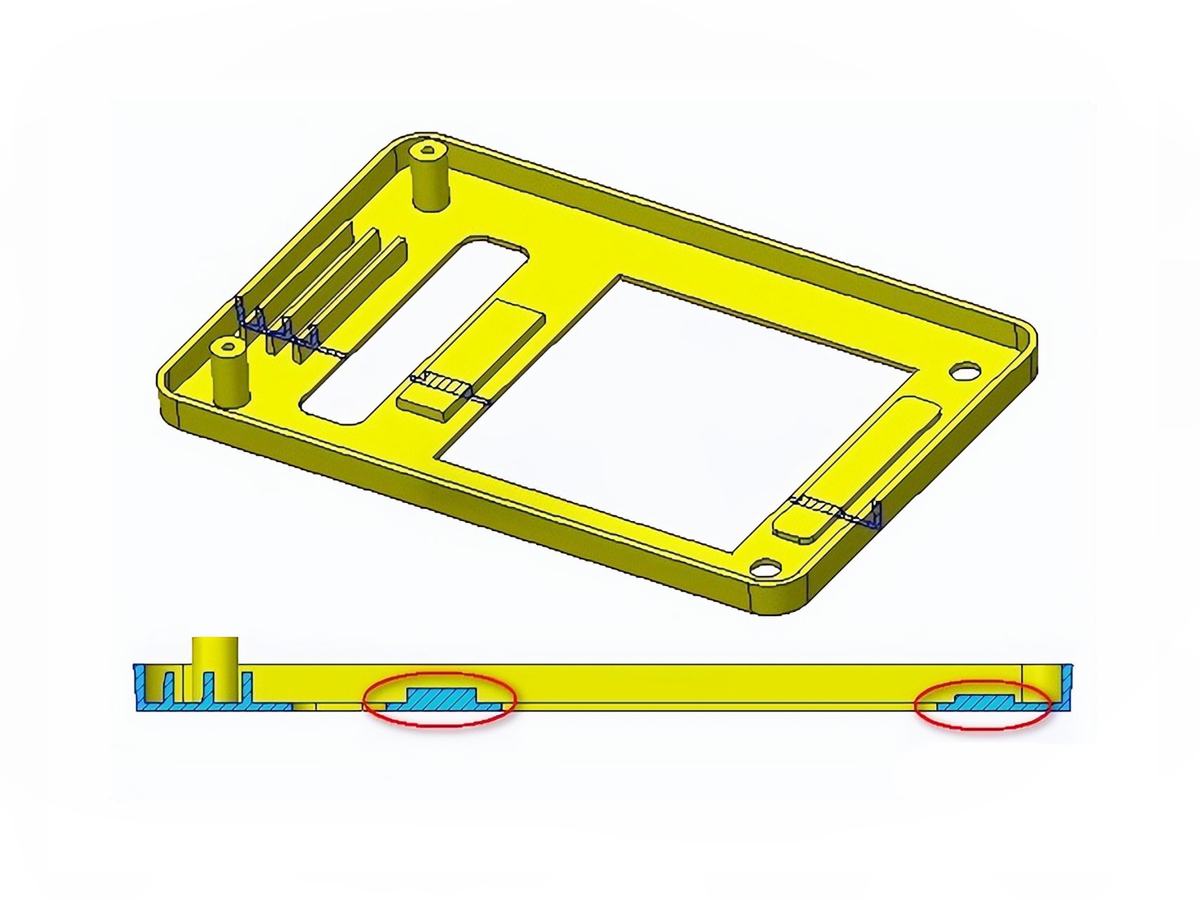

Draft and Radius Adjustments | Modifying features for easier mold release or tool access | Supports better flow in casting and lowers machining errors |

Designs are modeled in 3D CAD and evaluated for manufacturability using CAM toolpath simulation, mold flow analysis, and finite element analysis (FEA) where needed.

Benefits of Optimized Component Design

Area | Improvement | Impact |

|---|---|---|

Cost Efficiency | Material waste and tool time reduced | Saves up to 30% in production cost |

Quality and Consistency | Easier to machine or cast accurately | Reduces rejects and variation |

Faster Time to Market | Simplified setup and fabrication | Speeds up prototyping and first article approval |

Better Product Performance | Balanced strength, weight, and tolerances | Improves service life and reliability |

In a case study for an automotive bracket, revising the internal fillets and wall thickness reduced CNC cycle time by 27% while improving load-bearing capacity by 18% in FEA simulation.

Integration with Production Services

Optimized component designs are delivered in the form of manufacturing-ready 3D CAD models and 2D technical drawings, complete with:

GD&T according to ASME Y14.5

ISO 2768 or client-specified tolerance standards

Material specifications and post-processing instructions

They’re ready for production via:

CNC milling and turning

Our in-house engineers work closely with your team to validate the design, prototype the part if needed, and scale up to production with minimal disruption.

Applications of Design Optimization

Optimized part designs benefit a wide range of product categories:

Automotive: Engine brackets, heat sinks, pump housings

Industrial: Pneumatic blocks, valve bodies, gearboxes

Consumer Electronics: Casings, thermal components, fasteners

Medical Devices: Enclosures, surgical tools, instrument guides

Aerospace: Structural supports, fluid system components

Whether reducing the wall thickness of a die cast enclosure or simplifying the geometry of a machined bracket, design optimization leads to measurable gains across the board.

FAQs

What software tools are used in design optimization?

How does DFM affect lead time and production cost?

Can optimized designs be implemented on existing production lines?

Do you provide prototype testing after design revisions?

What industries benefit most from component design optimization?