Stringent Quality Control to Ensure Consistency in Mass Production

Introduction

Consistency is the cornerstone of successful mass production. As volumes scale into the tens or hundreds of thousands, even minor variations can lead to performance failures, costly recalls, and customer dissatisfaction. That’s why stringent quality control (QC) is not just a value-added service—it's a non-negotiable part of modern manufacturing.

At Neway, we implement comprehensive, data-driven quality control systems across die casting, CNC machining, and post-processing to ensure every part meets exacting specifications, regardless of batch size or complexity.

Why Quality Control is Critical in Mass Production

In high-volume manufacturing, defects scale as fast as output. A deviation of just 0.05 mm across 50,000 parts could result in tens of thousands of rejected components.

Key risks mitigated by strong QC include:

Dimensional deviation affecting fit and function

Surface defects such as porosity, flash, or pitting

Material inconsistencies leading to premature failure

Process drift in long production cycles

Improper post-processing (e.g., coating adhesion, thread fit)

By detecting and correcting these early, manufacturers can maintain productivity, reduce rework, and protect end-user trust.

Our Approach to Quality Control

Neway’s quality control framework is embedded in every stage of the manufacturing process. It includes:

1. Pre-Production Quality Planning

Design for Manufacturability (DFM) review with dimensional stack-up analysis

Tooling and fixture validation

Sample Approval (FAI) and PPAP documentation for critical parts

Material certification with traceability (e.g., A380, Zamak 5, C18200)

2. In-Process Control (IPQC)

In-line checks every 10–30 pieces, depending on criticality

Real-time SPC (Statistical Process Control) monitoring

Go/no-go gauges, dial indicators, and optical measurement

Machine alarms for tool wear, thermal deviation, and parameter shifts

For example, in high-speed CNC operations, we track tool offset variation with tolerance thresholds of ±0.002 mm, automatically adjusting to maintain quality within limits.

3. Post-Processing Inspection

Post-machining, casting, and surface treatment are followed by:

100% visual inspection under standardized lighting

Surface finish validation (Ra < 3.2 µm standard; Ra 0.8 µm for precision surfaces)

Coating thickness testing (powder: 60–80 µm; anodizing: 10–25 µm)

Fit and function checks for threaded features, mating surfaces, and assemblies

4. Final Quality Assurance

Before packaging and shipment:

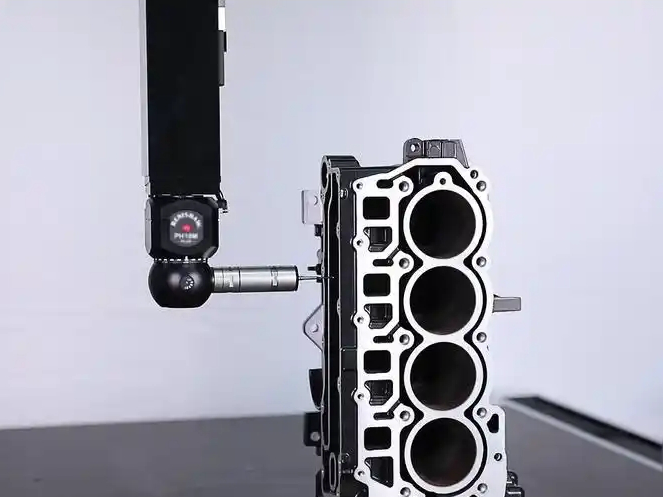

CMM (Coordinate Measuring Machine) verification of key dimensions

Leak testing for enclosed parts (up to 10 bar)

Functional tests (e.g., electrical continuity, mechanical motion)

Labeling, serialization, and full batch traceability

Real-Time Quality Tracking and Documentation

Our MES (Manufacturing Execution System) enables:

Real-time defect tracking by workstation and operator

Batch history logs linked to serial numbers or lot codes

Automated quality alerts and corrective action workflows

Exportable QA reports and inspection data for customers

All documentation can be shared upon request and formatted to meet industry standards such as ISO 9001, IATF 16949, or AS9102.

Case Example: Zero-Defect Policy for EV Component Production

A leading EV supplier required 300,000 aluminum sensor housings annually with <0.2% defect tolerance. Using A380 aluminum die casting and 5-axis CNC finish machining, we implemented:

Inline vision systems for flash and misalignment

Automated bore gauge validation for ±0.01 mm concentricity

Weekly destructive sample testing and metallographic analysis

Over 12 months, the defect rate averaged 0.06%, exceeding expectations and reducing customer QA time by 40%.

Benefits of a Strong Quality Control Program

Benefit | Description |

|---|---|

Dimensional consistency | Parts stay within ±0.005–0.01 mm range even in high-volume runs |

Lower scrap and rework | Reduces waste by catching process drift early |

Certification readiness | Prepares parts for use in aerospace, medical, or automotive sectors |

Traceable compliance | All data linked to batch, lot, and material certificates |

Brand and reputation protection | Delivers defect-free products to market with confidence |

Technologies and Tools Used

CMMs with micron-level precision

3D scanning for comparative geometry verification

Hardness testers, coating thickness meters, roughness testers

Vision systems with AI-driven detection of flash, cracks, or deformation

Digital SPC dashboards with automatic trend alerts

Conclusion

Quality isn’t an afterthought in mass production—it’s a system. At Neway, we embed quality control into every process to guarantee that every component meets your performance, safety, and consistency expectations.

From raw material verification to final CMM inspection, our comprehensive QC framework is designed to support the highest industry standards while keeping costs down and lead times short.

FAQs

What dimensional tolerances can Neway guarantee in mass production?

How is quality monitored during large-scale CNC machining?

What inspection methods are used for die cast surfaces?

Can customers receive quality reports and batch traceability documents?

What industry certifications support Neway’s QC processes?