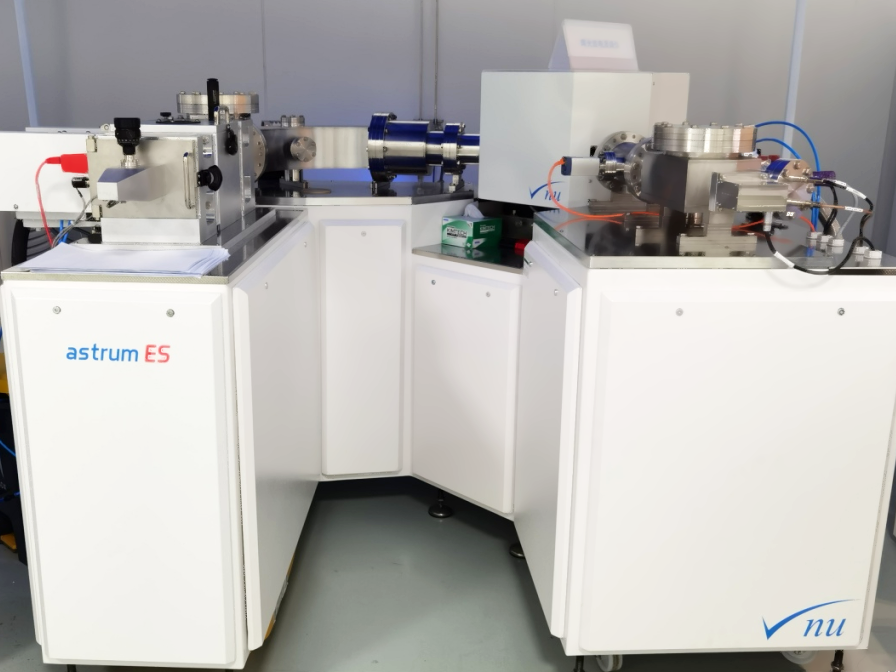

Ultra-Pure Alloy Verification: Glow Discharge Mass Spectrometer (GDMS) for Material Analysis

GDMS: Alloy Purity Assurance

In industries demanding atomic-level material precision—semiconductor fabrication, nuclear reactors, and biomedical implants—trace contaminants (≤0.1 ppb) can sabotage performance. Glow Discharge Mass Spectrometry (GDMS) detects impurities at parts-per-trillion (ppt) sensitivity, exceeding ASTM E3061 and ISO 17025 requirements for critical applications.

Neway’s Thermo Scientific™ Element GDMS systems analyze aerospace titanium, semiconductor-grade aluminum alloys, and nuclear zirconium, certifying compliance with ITAR, SEMI, and NASA standards.

GDMS Technology: Precision and Protocol

Operational Mechanism

Sputtering:

Argon plasma (5 kV, 5 mA) bombards the sample, ejecting atoms layer-by-layer (0.1–10 nm/s).

Ionization:

Atoms ionized via electron impact (70 eV) in a radio-free quadrupole cell.

Mass Separation:

Double-focusing magnetic sector (10,000 mass resolution) filters ions by m/z ratio.

Detection:

Combined Faraday cups (major elements) and ion counters (trace elements) achieve dynamic range >10⁹.

Performance Metrics

Detection Limits: 0.005 ppb (B, Li), 0.02 ppb (Fe, Ni), 0.1 ppb (U, Th).

Depth Profiling: 0.5 nm resolution for PVD coatings.

Throughput: 10 samples/8-hour shift with auto-loader.

Industry-Specific Applications

1. Semiconductor Manufacturing

Al-Si Targets (99.9999%):

Quantify sodium (<0.01 ppb) in AlSi12 to prevent transistor leakage.

Certify copper (<0.05 ppb) per SEMI F20 for 5nm node wafers.

2. Nuclear Fuel Cladding

Zr-4 Alloy Tubes:

Control hafnium (<50 ppm) and boron (<0.1 ppm) to maintain neutron economy.

3. Orthopedic Implants

Ti-6Al-4V ELI:

Ensure vanadium (<0.1 ppm) and aluminum (<0.5 ppm) meet ASTM F3001 biocompatibility.

GDMS vs. Competing Techniques

Parameter | GDMS | ICP-MS | SIMS |

|---|---|---|---|

Detection Limit | 0.005 ppb (B) | 0.1 ppb (B) | 0.1 ppb (B) |

Depth Resolution | 0.5 nm | N/A | 1 nm |

Matrix Effects | Minimal (conductive samples) | High (polyatomic interference) | Moderate (charging issues) |

Throughput | 8–12 samples/day | 20–30 samples/day | 4–6 samples/day |

Example: GDMS detected 0.2 ppb gold in high-purity copper inductors, causing RF signal loss. Switching to argon-shielded melting resolved the issue.

Quality Assurance Integration

Stage 1: Raw Material Vetting

Zinc Alloys:

Verify <0.01 ppb cadmium in Zamak 7 per RoHS Directive 2011/65/EU.

Stage 2: Process Validation

Vacuum Arc Remelting:

Monitor oxygen (<5 ppm) and nitrogen (<3 ppm) in Ti-6Al-4V during CNC machining.

Stage 3: Final Certification

Medical Grade NiTi:

Certify iron (<10 ppm) and cobalt (<0.5 ppm) per ISO 5832-11.

ROI and Compliance Benefits

Yield Enhancement:

Reduced gallium contamination in GaAs wafers from 0.8 ppb to <0.1 ppb, boosting yields by 12%.

Regulatory Compliance:

Achieved NADCAP accreditation for aerospace suppliers via AMS 2750-compliant reports.

Cost Avoidance:

Prevented $2.3M recall by detecting 1.2 ppb uranium in quantum chip copper interconnects.

Case Study: Satellite Component Failure Resolution

A GEO satellite manufacturer experienced intermittent signal loss in Ku-band transponders. GDMS analysis revealed:

Contaminant: 3.4 ppb tungsten from worn carbide tooling.

Root Cause: Tool abrasion during high-speed machining.

Solution: Switched to diamond-coated tools, eliminating tungsten ingress.

Conclusion

Neway’s GDMS services deliver ppt-level impurity control for mission-critical alloys, enabling compliance with MIL-STD-883, ITER MQS, and ISO 13485. From prototyping to full-scale production, we ensure materials meet the pinnacle of purity.

FAQs

What is the minimum sample thickness required for GDMS depth profiling?

Can GDMS analyze non-conductive ceramic coatings?

How are hydrogen and helium measured via GDMS?

What accreditation does Neway hold for GDMS testing?

Can GDMS differentiate isotopic ratios (e.g., ⁶Li vs. ⁷Li)?