المواد المناسبة للأنودة: أفضل المعادن لمعالجة الأسطح

Einleitung: Warum die Substratauswahl der erste Schritt zu erfolgreichem Anodisieren ist

Im Bereich der Oberflächenveredelung hängt die erfolgreiche Umsetzung des Anodisierens maßgeblich von der Wahl des richtigen Substrats ab. Als Oberflächenbehandlungsingenieur bei Newway erlebe ich häufig eine typische Realität: Wendet man denselben Anodisierprozess auf unterschiedliche metallische Substrate an, können völlig unterschiedliche Ergebnisse entstehen. Einige Metalle bilden robuste und langlebige anodische Schichten, während andere für diese Behandlung schlicht ungeeignet sind. Das Verständnis der Eigenschaften verschiedener Metalle und ihrer Kompatibilität mit dem Anodisieren ist entscheidend, damit das Endprodukt die gewünschte Leistung erreicht. Dieser Artikel bietet eine umfassende Betrachtung der am besten geeigneten Metalle für das Anodisieren und gibt Expertenhinweise zur Auswahl des passenden Substrats.

Aluminium und Aluminiumlegierungen: Der König des Anodisierens

Warum ist Aluminium die ideale Wahl?

Aluminium und seine Legierungen sind aufgrund ihrer einzigartigen Materialeigenschaften die idealen Substrate für das Anodisieren. Aluminium bildet an der Luft von Natur aus eine dünne Aluminiumoxidschicht, und Anodisieren ist im Wesentlichen ein elektrochemischer Prozess, der diese Oxidschicht gezielt verdickt und optimiert. Die künstlich erzeugte anodische Schicht besitzt eine poröse Struktur, eignet sich daher gut zum Färben und bietet nach dem Verdichten (Sealing) eine hervorragende Korrosionsbeständigkeit. Noch wichtiger: Aluminiumoxid ist deutlich härter als das Aluminiumsusbtrat und erhöht die Oberflächen-Verschleißfestigkeit erheblich.

Anwendungen und Herausforderungen bei Aluminium-Druckgusslegierungen

Im Bereich des Aluminium-Druckgusses sind A380 und ADC12 zwei häufig eingesetzte Legierungen. Obwohl diese Werkstoffe hervorragende Gießeigenschaften besitzen, stellt ihr relativ hoher Siliziumgehalt (typischerweise 7,5–12%) beim Anodisieren eine Herausforderung dar. Silizium kann die anodische Schicht dunkler oder gräulich erscheinen lassen und den Oberflächenglanz reduzieren. Um dem entgegenzuwirken, müssen Prozessparameter angepasst und spezielle Vorbehandlungen eingesetzt werden. Mit korrekt optimierten Prozessen lassen sich auch auf diesen Legierungen anodische Schichten mit guter Schutzwirkung erzielen – wobei der dekorative Effekt meist nicht so hochwertig ist wie bei siliziumarmen Legierungen.

Knetlegierungen aus Aluminium und High-End-Anwendungen

Für höherwertige Anwendungen, etwa in der Luft- und Raumfahrt oder in Premium-Consumer Electronics, werden häufig Knetlegierungen bevorzugt. Legierungen wie 6061, 6063 und 7075 mit geringerem Siliziumgehalt und homogenerer Mikrostruktur können sehr transparente Schichten mit hervorragender Färbbarkeit erzeugen. Nach geeigneter Anodisierung ermöglichen diese Legierungen eine große Farbauswahl bei gleichzeitig hoher Festigkeit und Korrosionsbeständigkeit.

Eine besondere Leichtbau-Option: Magnesiumlegierungen

Die Besonderheit des Anodisierens von Magnesiumlegierungen

Als leichtestes Konstruktionsmetall zeigt Magnesium beim Anodisieren ein deutlich anderes Verhalten als Aluminium. Magnesiumlegierungen benötigen spezielle Elektrolyte, die Fluoride enthalten, sowie anspruchsvollere Prozessbedingungen. Diese spezielle Anodisierbehandlung bildet eine keramikähnliche Beschichtung, die hauptsächlich aus Magnesiumfluorid besteht, und bietet eine sehr gute Verschleißfestigkeit sowie Korrosionsschutz.

Haupttypen und Anwendungsbereiche

Das Anodisieren von Magnesiumlegierungen wird im Allgemeinen in zwei Typen unterteilt: Dickschicht- und Dünnschichtsysteme. Dickschichtsysteme priorisieren einen hohen Korrosionsschutz und werden häufig in Automobilbauteilen sowie in der Luft- und Raumfahrt eingesetzt. Dünnschichtsysteme sind dekorativer und dienen als ideale Basis für eine nachfolgende Lackierung. Aufgrund ihrer hohen spezifischen Festigkeit und ihres ultraleichten Gewichts sind Magnesiumlegierungen besonders attraktiv für leichte 3C-Produkte wie Laptop-Gehäuse und portable Elektronik.

Titan und Titanlegierungen: Hochleistung und Biokompatibilität

Das Farbgeheimnis beim Anodisieren von Titan

Das Anodisieren von Titan und Titanlegierungen ist ein spezieller Prozess, der leuchtende Farben ohne Farbstoffe erzeugt. Der Färbemechanismus beruht auf optischer Interferenz: Durch präzise Steuerung von Anodisierspannung oder -strom wird die Dicke der Oxidschicht eingestellt. Unterschiedliche Schichtdicken verursachen unterschiedliche Interferenzeffekte – es entsteht ein breites Farbspektrum von Blau, Gold und Violett bis hin zu vielen weiteren Farbtönen.

Hauptanwendungsbereiche

Titananodisierung spielt eine entscheidende Rolle bei medizinischen Implantaten, da die entstehende Oxidschicht eine sehr gute Biokompatibilität bietet. In der Luft- und Raumfahrt erhalten anodisierte Titankomponenten nicht nur funktionale Kennzeichnungsfarben, sondern auch eine verbesserte Verschleißbeständigkeit. In hochwertigen Konsumgütern wie Uhrengehäusen und Brillenfassungen wird anodisiertes Titan wegen seines geringen Gewichts, hohen Tragekomforts und der unverwechselbaren Optik geschätzt.

Weitere Metalle, die anodisiert werden können

Einschränkungen von Zink und Zinklegierungen

Werkstoffe wie Zamak 3 und andere Zinklegierungen sind in der Regel für konventionelles Anodisieren ungeeignet. Zinkoxide, die sich in typischen Elektrolyten bilden, erzeugen keine stabile, schützende Schicht, und der Prozess kann zu starker Oberflächenkorrosion führen. Für Zinklegierungsteile empfehlen wir alternative Oberflächenbehandlungen wie Galvanisieren oder Lackieren, die besseren Schutz und attraktivere dekorative Ergebnisse liefern.

Tantal und Niob für Spezialanwendungen

Unter den seltenen Metallen können auch Tantal und Niob anodisiert werden, um attraktive Interferenzfarben zu erzeugen. Das Prinzip ähnelt dem von Titan, wobei die Farbe durch die Dicke der Oxidschicht bestimmt wird. Aufgrund ihrer hohen Kosten werden diese Metalle hauptsächlich in hochwertigem Schmuck und in ausgewählten Nischenanwendungen der Industrie eingesetzt.

Gängige Metalle, die für konventionelles Anodisieren ungeeignet sind

Stahl (einschließlich Edelstahl)

Stahl kann durch traditionelles Anodisieren keine wirksame Schutzschicht bilden. Die Eisenoxide, die sich unter natürlichen oder elektrolytischen Bedingungen bilden, sind porös und nicht schützend und können Korrosion oft sogar beschleunigen statt verhindern. Für Stahlkomponenten empfehlen wir Pulverbeschichtung, Galvanisieren oder andere Beschichtungstechnologien, um die gewünschte Leistung und Optik zu erreichen.

Kupfer und Kupferlegierungen

Auch Kupfer und seine Legierungen können durch konventionelles Anodisieren keine stabilen anodischen Schichten bilden. Kupferoxide sind nicht zuverlässig schützend und neigen dazu, unter unterschiedlichen Umgebungsbedingungen unvorhersehbar die Farbe zu verändern, was schwer kontrollierbar ist. Für Kupferteile empfehlen wir in der Regel Galvanisieren, Passivieren oder chemische Färbeprozesse.

Schlüsselfaktoren bei der Auswahl und Optimierung von Substraten für Ihr Projekt

Legierungsreihen und Einfluss von Legierungselementen

Art und Anteil der Legierungselemente beeinflussen die Anodisierqualität entscheidend. Silizium neigt dazu, die anodische Schicht zu verdunkeln; ein zu hoher Kupferanteil kann die Schichtgleichmäßigkeit und Korrosionsbeständigkeit beeinträchtigen; während geeignete Mengen an Magnesium und Zink (innerhalb bestimmter Grenzen) einige Schichteigenschaften verbessern können. Durch Druckguss-Engineering-Analysen können wir den Einfluss dieser Elemente bereits in der Konstruktionsphase vorhersagen und optimieren.

Die Bedeutung der Mikrostruktur

Eine feine und gleichmäßige Mikrostruktur ist die Grundlage für hochwertige anodische Schichten. Bei Druckgussteilen können T5/T6-Wärmebehandlungen helfen, die Struktur zu homogenisieren und Entmischungen zu reduzieren. Gleichzeitig ist die Kontrolle der Erstarrung – durch geeignete Werkzeugkonstruktion und Prozessparameter – entscheidend, um die Substratqualität und eine konsistente Anodisierleistung sicherzustellen.

Design und Oberflächenvorbehandlung

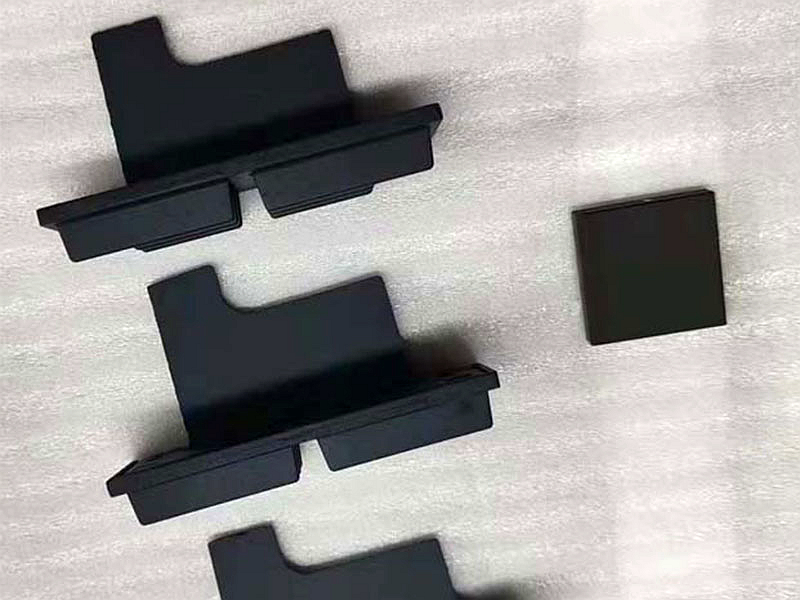

Ein gutes Produktdesign erhöht die Erfolgswahrscheinlichkeit beim Anodisieren erheblich. Mit Unterstützung von Druckguss-Design-Services lassen sich Merkmale wie scharfe Kanten, tiefe Sacklöcher und enge Spalte, die Elektrolytfluss und Wärmeabfuhr behindern, minimieren oder vermeiden. Vor dem Anodisieren kann Sandstrahlen eine gleichmäßige matte Oberfläche erzeugen, während CNC-Bearbeitung ein glattes, glänzendes Finish liefern kann. Diese Vor- und Nachbearbeitungs-Schritte schaffen eine stabile Basis für gleichmäßige, hochwertige anodische Beschichtungen.

Fazit: Das richtige Substrat ist die Basis für exzellente Oberflächenbehandlung

Die Auswahl des geeigneten metallischen Substrats ist die wichtigste Voraussetzung für ideale Anodisierungsergebnisse. Aluminium und seine Legierungen bleiben die am weitesten verbreitete und ausgewogenste Wahl; Magnesiumlegierungen bieten besondere Vorteile für Leichtbauanwendungen; Titanlegierungen sind unverzichtbar, wenn es um Hochleistung und spezielle Optik geht. Durch die Zusammenarbeit mit Lieferanten, die über starke Materialkompetenz verfügen und One-Stop-Services anbieten, sowie durch die frühzeitige Berücksichtigung von Substratauswahl und Prozesskompatibilität schon in der Designphase, können Sie im Endprodukt ein optimales Gleichgewicht aus Leistung, Optik und Kosten erreichen.

FAQ

Why do my die-cast aluminum parts appear uneven or dark after anodizing?

Is the corrosion resistance of anodized magnesium alloys sufficient for everyday use?

Are the colors of anodized titanium alloys stable, or will they fade over time?

Can Newway assist us in testing and selecting the most suitable aluminum alloy grade for anodizing?