فوائد الأنودة بالقوس الكهربائي: الأداء والمتانة وقيمة التصميم

القيمة الأساسية للأنودة القوسية

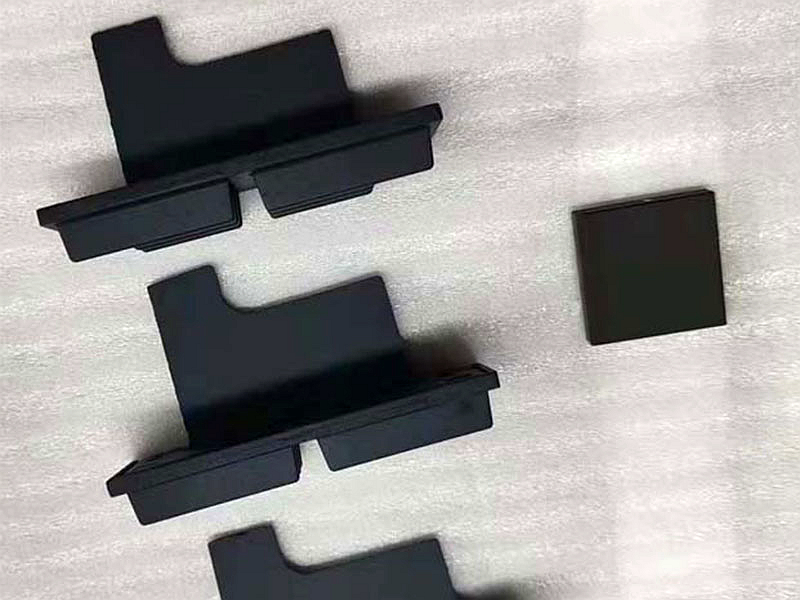

بصفتي مهندسًا في Neway، أعمل مباشرةً مع مكوّنات يجب أن تؤدي أداءً موثوقًا في ظروف قاسية تشمل الدورات الحرارية والإجهاد الميكانيكي والأجواء المسببة للتآكل والتعرّض الكهربائي. أصبحت الأنودة القوسية—المعروفة أيضًا بالأكسدة بالميكرو-قوس (MAO)—إحدى أكثر تقنيات الطلاء التحويلي الخزفي تنوعًا لتعزيز هذه المكوّنات. وعلى عكس الأنودة التقليدية، تعتمد MAO على تفريغ بلازمي يُنشئ أكسيدًا خزفيًا كثيفًا مقاومًا للاهتراء ويوفّر عزلًا كهربائيًا عاليًا.

عبر صناعات متعددة—من الطيران إلى الإلكترونيات الاستهلاكية—تطورت الأنودة القوسية إلى أسلوب استراتيجي لهندسة السطح يرفع موثوقية المكوّنات ويطيل عمر الخدمة ويضيف قيمة تصميمية مميزة. وعند دمجها مع طرق التصنيع السابقة مثل صب الألومنيوم بالقوالب أو التشغيل باستخدام CNC، يمكن تحسين الطلاء بالكامل لتحقيق أداء أفضل وكفاءة تكلفة أعلى وقابلية تكرار مستقرة في الإنتاج.

مزايا الأداء الهيكلي

تشكّل طبقة نانو-خزفية

تُكوّن الأنودة القوسية طبقة خزفية تتكون أساسًا من أكاسيد من نوع الكورندوم والموليت. تُشكّل هذه الأطوار بنية مزدوجة الطبقة تتضمن حاجزًا خارجيًا كثيفًا وطبقة انتقالية أكثر متانة وأعلى ليونة. يتيح هذا البناء الطبقي للمكوّنات المنتجة عبر صب الزنك بالقوالب أو صب النحاس بالقوالب تحمّل البيئات الميكانيكية القاسية.

صلادة عالية ومقاومة ممتازة للاهتراء

غالبًا ما تُظهر طلاءات MAO مستويات صلادة تتجاوز الأنودة التقليدية بعدة مراتب. وفي الصناعات التي يشيع فيها الاهتراء الانزلاقي أو التآكل بالجسيمات، تُحسّن هذه الخاصية عمر الخدمة الوظيفي بشكل كبير.

مقاومة التآكل والثبات الكيميائي

من أكثر جوانب الأنودة القوسية قيمةً قدرتها على مقاومة التآكل. فالطبقة الخزفية تقاوم الأكسدة ورذاذ الملح والتعرّض الكيميائي. وهذا مهم للغاية للهياكل الحاملة، وأغطية بطاريات المركبات الكهربائية، والمكوّنات الخارجية عالية المتطلبات.

الثبات الحراري ومقاومة الصدمة الحرارية

تتحمل MAO التعرض لدرجات حرارة مرتفعة، ما يجعلها مناسبة للمنتجات التي تواجه أحمالًا حرارية مستمرة. تستفيد سبائك الألومنيوم مثل A380 وADC12 من هذه الحماية الإضافية، بما يحسن أداءها في حجرات المحركات والتدريع الإلكتروني وأغلفة الإدارة الحرارية.

العزل الكهربائي وقوة العزل

يعزز الطلاء الخزفي قوة العزل (Dielectric Strength) بشكل ملحوظ. وبالنسبة لمصممي أغلفة الإلكترونيات، يفتح ذلك المجال لجدران أرق ومنتجات أخف وزنًا. ولهذا السبب تُستخدم MAO كثيرًا في أغلفة الإلكترونيات الاستهلاكية.

المتانة طويلة الأجل وقيمة دورة الحياة

إطالة عمر المكوّن

تحمي طبقة الأكسيد الخزفي في الأنودة القوسية المكوّنات من أكثر أشكال التدهور شيوعًا—الاهتراء والتآكل والتعرية الحرارية—ما يطيل عمر الخدمة مباشرةً ويقلل دورات الاستبدال.

تقليل متطلبات الصيانة

يستفيد المصنعون الصناعيون من تقليل فترات التوقف غير المخطط لها. سواءً لحوامل الطيران، أو مكوّنات مجموعة الحركة في السيارات، أو الأغلفة الميكانيكية، فإن الطلاء الخزفي المستقر يقلل إجمالي تكلفة الملكية.

ثبات الأداء في البيئات القاسية

تُظهر المكوّنات المعرّضة للبيئات البحرية أو الكيميائية أو عالية الحرارة قدرة أكبر على الاحتفاظ بسلامتها الهيكلية لمدة أطول. وهذا يجعل الأنودة القوسية خيارًا مناسبًا للعديد من مكوّنات الطيران التي يجب أن تؤدي أداءً ثابتًا تحت ظروف طيران متغيرة.

مقاومة التدهور الناتج عن الاهتراء

يؤدي التلامس الانزلاقي المستمر والاحتكاك المتكرر والتعرّض للجسيمات إلى تدهور الأسطح المعدنية غير المطلية تدريجيًا. وتُبطئ البنية البلورية في MAO هذا الضرر بشكل كبير.

قيمة التصميم والمزايا الجمالية

ملمس ميكروي فريد وإحساس سطحي مميز

تُنتج الأنودة القوسية سطحًا خزفيًا ذا نسيج ميكروي طبيعي يمنح المنتجات إحساسًا لمسيًا فاخرًا. وغالبًا ما يستغل المصممون هذه السمة لتمييز المنتجات الاستهلاكية الراقية.

ثبات اللون والتعبير الزخرفي

رغم أن MAO وظيفية بالدرجة الأولى، فإن بعض السبائك تدعم تشطيبات زخرفية. يتيح ذلك تخصيصًا بصريًا دون التضحية بالمتانة.

مظهر فاخر للمنتجات الاستهلاكية والصناعية

سواء كان المنتج غلاف حاسوب محمول أو هيكل جهاز ذكي أو أداة صناعية محمولة، تعزز MAO المتانة والانطباع العام بالجودة.

دمج الوظيفة مع الجماليات

بالنسبة للهياكل المبددة للحرارة، يمكن لـ MAO تحسين الانبعاثية الحرارية مع رفع المظهر العام. هذه الفائدة المزدوجة جذابة في تطبيقات مثل الأغلفة الحرارية ووحدات المركبات الكهربائية وأغلفة تخزين الطاقة.

مزايا مقارنةً بالأنودة التقليدية

سماكة وصلادة أعلى

تنتج الأنودة التقليدية عادةً طبقات أكسيد أرق. أما الأنودة القوسية فتوفر طبقات خزفية أكثر سماكة—وغالبًا أقوى بعدة مرات—ما يجعلها مثالية للبيئات عالية الحمل أو عالية الاهتراء.

عمر اهتراء أطول وقوة ميكانيكية أفضل

تستفيد التطبيقات التي تتضمن أسطح أدوات أو واجهات انزلاقية أو غبارًا كاشطًا من عمر الاهتراء الاستثنائي في MAO.

ملاءمة للتطبيقات عالية الحرارة

تقاوم الطبقات الخزفية في MAO التليّن والأكسدة عند درجات حرارة تتجاوز بكثير حدود ما تستطيع الأنودة التقليدية تحمله.

حالات استخدام وظيفية وزخرفية

تسد MAO الفجوة بين أداء الطلاء الوظيفي والجماليات البصرية، وهو تفوق يصعب تحقيقه عبر الأنودة التقليدية.

أداء الركائز المختلفة

أداء سبائك الألومنيوم

يبقى الألومنيوم أكثر الركائز توافقًا. وتستجيب مجموعات مختلفة من سبائك الألومنيوم بشكل متفاوت مع MAO. فعلى سبيل المثال، تُشكّل درجات صب القوالب عالية السيليكون مثل AlSi10Mg طبقات عالية المقاومة للاهتراء، بينما تُنتج السبائك المشغولة أسطحًا أكثر نعومة.

أداء سبائك المغنيسيوم

تحقق مكوّنات المغنيسيوم تحسنًا كبيرًا في مقاومة الاهتراء والتآكل. وفي التصاميم خفيفة الوزن التي تُحسب فيها كل غرامات، تصبح MAO معززًا حاسمًا للمتانة.

أداء سبائك التيتانيوم

يوفر التيتانيوم عند معالجته بـ MAO توافقًا حيويًا ممتازًا وخصائص سطحية عالية القوة، ما يجعله مناسبًا لحوامل متخصصة ومكوّنات طبية وأجزاء عزل عالية المتطلبات.

سلوك سبائك الزنك والنحاس

رغم أن ذلك أقل شيوعًا، يمكن تطبيق MAO على سبائك الزنك ضمن شروط محسّنة. ويكون سلوك البلازما أكثر حساسية على هذه المواد، ما يتطلب ضبطًا دقيقًا للمعايير الكهربائية.

التوافق مع تدفق التصنيع

التكامل مع عمليات الصب بالقوالب

تعمل الأنودة القوسية بشكل ممتاز مع مكوّنات الألومنيوم المصبوبة بالضغط العالي. وعند دمجها مع عمليات مثل أنودة المسبوكات بالقوالب، يمكن تخصيص استراتيجيات تشطيب هجينة لتحقيق توازن بين الأداء والتكلفة.

التوافق مع التشغيل باستخدام CNC

تساعد المكوّنات المُحسّنة عبر CNC على تجانس MAO بشكل أفضل. كما يقلل تشطيب السطح المتحكم به من مناطق التفريغ المفرط (Hotspots) ويزيد كثافة الطلاء.

المواءمة مع تطوير النماذج الأولية والإنتاج

في مراحل التطوير المبكرة، تُسرّع النمذجة السريعة اختبار MAO عبر توفير أجزاء تجريبية دقيقة قبل الالتزام بقوالب الإنتاج.

تعزيز الأداء عبر المعالجات اللاحقة

بعد MAO، تُحسن عمليات السدّ والتشطيبات الميكانيكية مقاومة التآكل واتساق السطح بشكل إضافي.

قيمة التطبيق حسب الصناعة

هندسة الطيران

تخدم متانة الأنودة القوسية وقوة العزل ومقاومة الحرارة الأغلفة الهيكلية والحوامل والوحدات المعرضة لبيئات طيران قاسية.

تطبيقات السيارات

تعتمد أغلفة بطاريات المركبات الكهربائية، وأغلفة مجموعة الحركة، والهياكل ذات الأهمية للسلامة غالبًا على MAO لتحقيق أهداف الأداء. وتوضح حلول الصب للسيارات لدينا كيف يؤدي دمج خبرة الصب مع MAO إلى مكوّنات قوية وطويلة العمر.

الإلكترونيات الاستهلاكية

تستخدم الأغلفة الراقية المطوّرة ضمن مشاريع أغلفة الإلكترونيات الاستهلاكية MAO لتحقيق مظهر فاخر مع مقاومة خدش استثنائية.

المعدات الصناعية

في البيئات الشاقة، تعزز طلاءات MAO العزل ومقاومة الاهتراء للأغلفة الدقيقة والصمامات والمكوّنات الهيكلية.

تحسين التصميم والمنفعة مقابل التكلفة

DFAA (التصميم للأنودة القوسية)

يساعد تحسين أنصاف الأقطار وتوزيع سماكة الجدار ومناطق حساسية التفريغ على تعزيز تجانس الطلاء وخفض معدلات الهدر.

تأثير اختيار المادة

يقلل اختيار السبيكة المناسبة من استهلاك الطاقة ويحسن اتساق الطلاء. وعند استخدام مكوّنات مصبوبة ضمن خدمة الصب بالقوالب الشاملة، يصبح اختيار المادة جزءًا مدمجًا من خطة الإنتاج بالكامل.

تكلفة دورة حياة أقل

رغم أن MAO أعلى تكلفة من الأنودة التقليدية، إلا أن متانتها الممتدة تخفض التكلفة طويلة الأجل عبر تقليل الصيانة والأعطال والاستبدال.

التكامل مع التصنيع المتكامل

تُحقق المشاريع التي تستفيد من تكامل الصب والتشغيل والطلاء—المتاح ضمن نموذج Neway المتكامل رأسيًا—اتساقًا أعلى وأزمنة دورة أقل.

قيمة الاستدامة في الأنودة القوسية

تقليل الصيانة والاستبدال

يعني عمر المنتج الأطول أن عددًا أقل من المكوّنات يحتاج إلى تصنيع ونقل وإعادة تدوير.

دعم هندسة تخفيف الوزن

تُمكّن MAO تصنيع هياكل معدنية أرق وأخف دون التضحية بالمتانة، ما يساهم في رفع كفاءة الطاقة في النقل والإلكترونيات.

هندسة سطح صديقة للبيئة

مقارنةً بطلاءات خزفية أخرى، تستخدم MAO إلكتروليتات أقل ضررًا بيئيًا وتحد من الانبعاثات السامة.

الخلاصة ونقاط هندسية أساسية

توفّر الأنودة القوسية مزيجًا نادرًا من المتانة الميكانيكية ومقاومة التآكل والثبات الحراري والعزل الكهربائي والجاذبية البصرية. بالنسبة للمهندسين الذين يطوّرون مكوّنات الجيل القادم، تمنح MAO مزايا كبيرة في الأداء والتكلفة، خاصةً عند دمجها ضمن سير عمل إنتاج متكامل عبر خدمة الأنودة القوسية. ومن أغلفة الطيران إلى الإلكترونيات الاستهلاكية، تواصل MAO مساعدة المصنعين على رفع الموثوقية وإطالة دورة الحياة وتعزيز جماليات المنتج.