تصنيفات الأنودة: الأنواع والمعايير الصناعية

Einleitung: Warum das Verständnis von Anodisierungs-Klassifikationen wichtig ist

Bei der Oberflächenbehandlung von Aluminium und Aluminiumlegierungen spielt das Anodisieren eine entscheidende und unersetzliche Rolle. Als Oberflächenveredelungsingenieur bei Newway weiß ich aus Erfahrung, dass die Wahl der richtigen Anodisierungsart die Produktleistung, Lebensdauer und Wettbewerbsfähigkeit am Markt maßgeblich beeinflusst. Unterschiedliche Anodisierungs-Klassifikationen unterscheiden sich nicht nur optisch; vor allem unterscheiden sie sich deutlich hinsichtlich Korrosionsbeständigkeit, Verschleißfestigkeit, Isoliereigenschaften und dekorativer Wirkung. Dieser Artikel führt Sie durch die wichtigsten Anodisierungs-Klassifikationen und die dazugehörigen Industriestandards, damit Sie die passendste Oberflächenbehandlung für Ihre Produkte auswählen können.

Grundprinzipien des Anodisierens

Was ist Anodisieren?

Anodisieren ist ein elektrochemischer Prozess, bei dem auf der Oberfläche von Aluminium und Aluminiumlegierungen eine dichte Oxidschicht gebildet wird. Dabei dient das Aluminiumbauteil als Anode. Fließt Strom in einem geeigneten Elektrolyten, wächst auf der Oberfläche eine poröse Aluminiumschicht (Aluminiumoxid). Diese Oxidschicht ist fest mit dem Grundwerkstoff verbunden und besitzt besondere Eigenschaften, die die Oberflächenmerkmale deutlich verbessern.

Gemeinsame Grundlage, unterschiedliche Wege

Obwohl alle Anodisierungsarten auf demselben elektrochemischen Prinzip beruhen, lassen sich durch die Anpassung von Parametern wie Elektrolyt-Zusammensetzung, Konzentration, Temperatur, Spannung und Stromdichte Oxidschichten mit unterschiedlichen Eigenschaften erzeugen. Diese Flexibilität ermöglicht es, Anforderungen von rein dekorativen Oberflächen bis hin zu hochfunktionalen Beschichtungen abzudecken.

Typ I: Chromsäure-Anodisieren

Prozess und Eigenschaften

Beim Chromsäure-Anodisieren wird eine 3–10%ige Chromsäurelösung als Elektrolyt unter vergleichsweise milden Prozessbedingungen verwendet. Es entsteht eine relativ dünne Oxidschicht, typischerweise 0,5–5 µm, mit einem opaken Erscheinungsbild von hellgrau bis dunkelgrau. Die größten Vorteile sind eine minimale Beeinflussung der Ermüdungsfestigkeit des Grundwerkstoffs, kombiniert mit guter Korrosionsbeständigkeit und hervorragender Lackhaftung. Dadurch eignet sich dieses Verfahren besonders für Präzisions-Strukturteile und dünnwandige Komponenten.

Hauptanwendungsbereiche

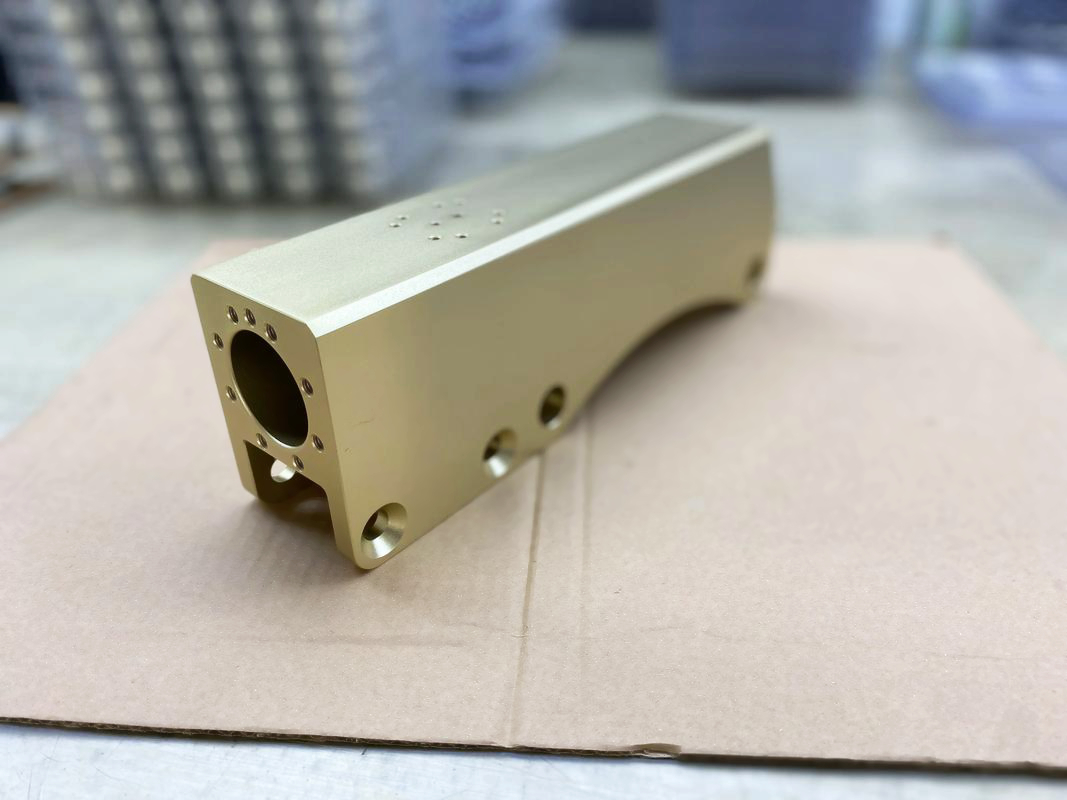

Chromsäure-Anodisieren wird in der Luft- und Raumfahrt sowie in der Verteidigungsindustrie häufig für die Oberflächenbehandlung von Präzisionsteilen eingesetzt. Es ist besonders effektiv für komplexe Bauteile aus Aluminium-Druckguss, da es selbst in tiefen Bohrungen und komplizierten Geometrien eine gleichmäßige Schichtbildung ermöglicht. Für Präzisionsteile, die eine Nachbearbeitung von Druckgussteilen erfordern, trägt dieses Verfahren dazu bei, die Maßhaltigkeit nach der Bearbeitung sicherzustellen.

Relevante Industriestandards

Chromsäure-Anodisieren wird hauptsächlich durch Standards wie MIL-A-8625 Typ I und AMS 2470 geregelt. Diese Standards definieren Anforderungen an Schichtgewicht, Korrosionsbeständigkeit, Versiegelungsqualität und weitere zentrale Leistungskennwerte. So fordert MIL-A-8625 beispielsweise ein Mindest-Schichtgewicht von 200 mg/dm² sowie den Nachweis der Korrosionsbeständigkeit durch anspruchsvolle Salzsprühprüfungen.

Typ II: Schwefelsäure-Anodisieren

Prozess und Eigenschaften

Schwefelsäure-Anodisieren ist die am häufigsten verwendete Anodisierungsart und nutzt eine 15–20%ige Schwefelsäurelösung als Elektrolyt. Die resultierende Oxidschicht kann in einem breiten Dickenbereich liegen, typischerweise 1,8–25 µm. Aufgrund ihrer porösen Struktur und hohen Transparenz eignet sie sich sehr gut zum Färben und ermöglicht eine große Farbvielfalt. In Bezug auf das Kosten-Nutzen-Verhältnis bietet das Schwefelsäure-Anodisieren klare Vorteile.

Hauptanwendungsbereiche

Im Bereich der Unterhaltungselektronik wird Schwefelsäure-Anodisieren umfassend eingesetzt. Beispielsweise wird die ikonische metallische Optik vieler Apple-Produkte durch gefärbte anodisierte Oberflächen erreicht. Auch Architektur-Beschläge, Automotive-Innenraumkomponenten und andere Produkte mit dekorativen Anforderungen nutzen dieses Verfahren häufig. Unser Zentrum für Anodisierungs-Services ist mit fortschrittlichen Färbe- und Farbkontrollsystemen ausgestattet und ermöglicht präzises Farbmatching für unsere Kunden.

Relevante Industriestandards

Schwefelsäure-Anodisieren wird unter anderem durch MIL-A-8625 Typ II, AMS 2471 und ASTM B580 definiert. Diese Standards legen klare Anforderungen an Schichtdicke, Farbechtheit, Versiegelungsqualität und verwandte Eigenschaften fest. So wird bei anodisierten Architektur-Aluminiumprofilen typischerweise eine Mindestschichtdicke von 10 µm gefordert, während für Außenanwendungen häufig 15–25 µm spezifiziert werden.

Typ III: Hartanodisieren

Prozess und Eigenschaften

Hartanodisieren verwendet einen ähnlichen Elektrolyten wie das Schwefelsäure-Anodisieren (Typ II), jedoch unter deutlich anspruchsvolleren Prozessbedingungen. Der Prozess erfolgt bei niedrigen Temperaturen nahe 0 °C und mit höheren Stromdichten. Dadurch entstehen wesentlich dickere Oxidschichten, typischerweise 25–100 µm oder mehr, mit Härtewerten über HV500, was eine herausragende Verschleiß- und Korrosionsbeständigkeit bietet.

Hauptanwendungsbereiche

Hartanodisieren wird vor allem in rauen Einsatzumgebungen eingesetzt, in denen Bauteile starkem Verschleiß und Korrosion widerstehen müssen. Typische Anwendungen sind Hydrauliksysteme, Zylinder, Getriebekomponenten und andere mechanische Teile, bei denen die Standzeit deutlich verlängert werden soll. Bei Automobilkomponenten bietet Hartanodisieren einen zuverlässigen Schutz für kritische Teile, etwa in Brems- und Getriebesystemen.

Relevante Industriestandards

Hartanodisieren wird durch Standards wie MIL-A-8625 Typ III, MIL-A-63576 und AMS 2472 definiert. Diese Standards stellen strenge Anforderungen an Schichthärte, Schichtdicke, Verschleißfestigkeit und Korrosionsbeständigkeit. So fordert AMS 2472 beispielsweise eine Mindesthärte von HV300 für Hartanodisierungsschichten und verlangt Prüfungen nach festgelegten Taber-Verschleißverfahren.

Neue Technologie: Arc-Anodisieren

Prozess und Eigenschaften

Arc-Anodisieren, auch bekannt als Micro-Arc Oxidation (MAO), ist ein spezielles Anodisierungsverfahren, das bei deutlich höheren Spannungen durchgeführt wird. Durch Mikro-Lichtbogenentladungen auf der Metalloberfläche bildet sich eine keramikähnliche Beschichtung mit einer Dicke von etwa 50–200 µm und Härtewerten, die HV1000 überschreiten können. Diese Schichten bieten eine exzellente Haftung, eine herausragende Hochtemperaturbeständigkeit sowie überlegene elektrische Isoliereigenschaften.

Hauptanwendungsbereiche

In hochwertigen Automobil-Anwendungen wird Arc-Anodisieren bei Motorkomponenten, Turboladerteilen und anderen Bauteilen eingesetzt, die erhöhten Temperaturen ausgesetzt sind. Auch die Luft- und Raumfahrt, die petrochemische Industrie sowie die Medizintechnik übernehmen diese fortschrittliche Oberflächentechnologie zunehmend. Unsere Arc-Anodisierungs-Services haben bereits innovative Lösungen für Kunden in diesen Branchen erfolgreich umgesetzt.

Relevante Standards und fortlaufende Entwicklung

Da es sich um eine relativ neue Technologie handelt, befindet sich die Standardisierung für Arc-Anodisieren noch in der Entwicklung. Aktuelle Praxis orientiert sich vor allem an passenden ASTM- und ISO-Prüfmethoden sowie an branchenspezifischen Spezifikationen. Mit zunehmender Reife der Technologie und wachsender Anwendung wird schrittweise ein umfassenderes und präziseres Standardsystem etabliert.

Wie Sie die richtige Anodisierungsart für Ihr Projekt wählen

Entscheidungsmatrix: Leistungsanforderungen priorisieren

Bei der Auswahl der Anodisierungsart ist der erste Schritt, die wichtigsten Leistungsanforderungen Ihres Produkts zu klären. Wenn dekorative Optik und eine große Farbvielfalt im Vordergrund stehen, ist Typ II (Schwefelsäure-Anodisieren) meist die beste Wahl. Für Werkzeuge, Formen oder bewegte Komponenten mit hoher Verschleißanforderung ist Typ III (Hartanodisieren) besser geeignet. Präzisionsbauteile in der Luft- und Raumfahrt profitieren häufig von Typ I (Chromsäure-Anodisieren). Für Komponenten, die unter extremen Bedingungen arbeiten, sollte Arc-Anodisieren in Betracht gezogen werden.

Material- und Designaspekte

Verschiedene Aluminiumlegierungen reagieren sehr unterschiedlich auf das Anodisieren. So lässt sich die Legierung A360 im Allgemeinen gut anodisieren und eignet sich für die meisten Verfahren, während A380 gegebenenfalls eine spezielle Vorbehandlung erfordert. Bereits in der Konstruktionsphase kann die Zusammenarbeit mit Druckguss-Design-Services helfen, scharfe Kanten, tiefe Sacklöcher und andere Geometrien zu vermeiden, die eine gleichmäßige Schichtbildung erschweren – und so eine konsistente Beschichtungsqualität sicherzustellen.

Kosten- und Lieferkettenfaktoren

Aus Kostensicht ist Typ II in der Regel am wirtschaftlichsten, gefolgt von Typ I und Typ III, während Arc-Anodisieren die teuerste Option ist. Bei der Auswahl müssen Produktpositionierung, erwartete Lebensdauer und Budgetrestriktionen ausbalanciert werden. Eine Zusammenarbeit mit einem professionellen Anbieter, der One-Stop-Services bietet, kann helfen, die gesamte Prozesskette zu optimieren und die Gesamtbetriebskosten zu senken.

Fazit: Präzise Auswahl für überlegene Produktleistung

Die Vielfalt der Anodisierungstechnologien ermöglicht zielgerichtete Lösungen für unterschiedliche Anwendungsszenarien. Von dekorativem Typ II über funktionalen Typ III, von präzisionsorientiertem Typ I bis hin zum fortschrittlichen Arc-Anodisieren – jede Klassifikation besitzt ihr eigenes, einzigartiges Nutzenprofil. Die richtige Wahl verbessert nicht nur die Optik, sondern steigert auch Funktionalität, Dauerhaftigkeit und Zuverlässigkeit erheblich. Als Ihr professioneller Partner für Oberflächenbehandlung setzt sich Newway dafür ein, die geeignetsten Anodisierungslösungen bereitzustellen, damit Ihre Produkte in einem stark umkämpften Markt hervorstechen.

FAQ

Can Type II anodizing achieve the same hardness as Type III hard anodizing?

What are the environmental and health impacts of Type I chromic acid anodizing?

Does Type III hard anodizing cause dimensional changes in parts?

Which type of anodizing is most suitable for my die-cast aluminum parts (such as ADC12)?

Can Newway provide anodizing services comply with industry standards such as MIL and AMS?