تصنيفات الأنودة بالقوس الكهربائي: المعايير والأنواع والتطبيقات

مقدمة عن الأنودة القوسية

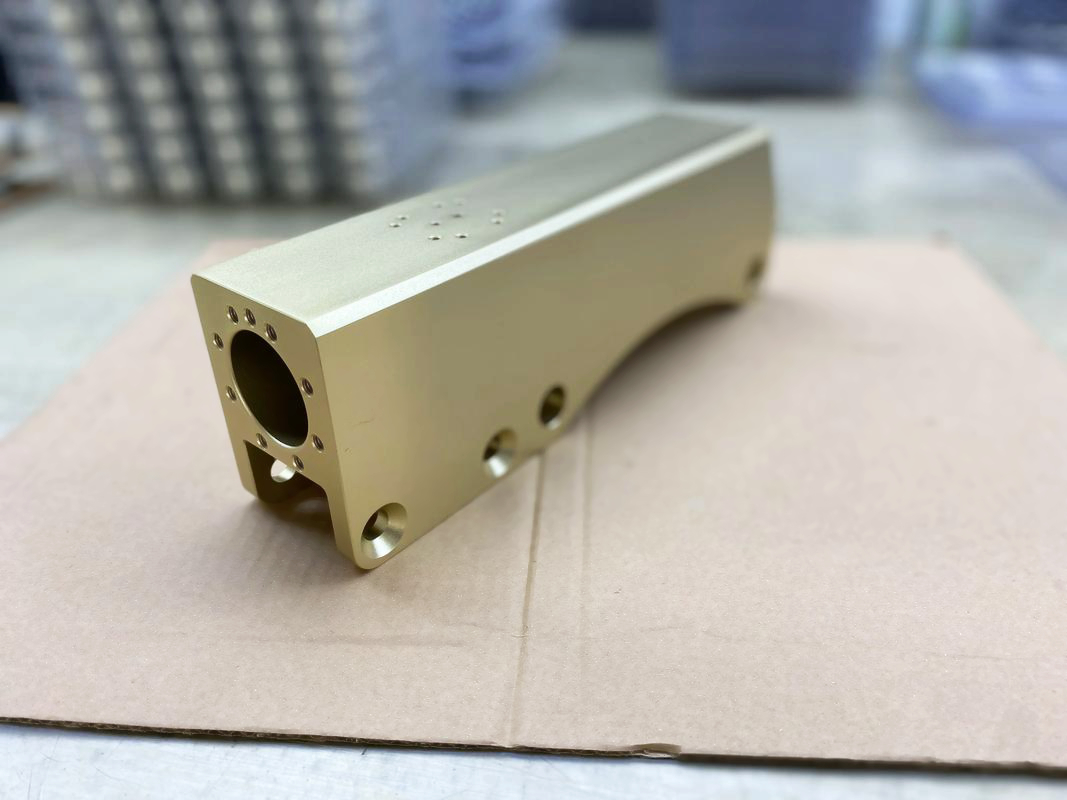

بصفتي مهندسًا في Neway، أتعامل كثيرًا مع مكوّنات يجب أن تصمد أمام بيئات عدوانية، وأحمال حرارية عالية، وظروف ميكانيكية قاسية. تُعد الأنودة القوسية—والتي يُشار إليها عادةً باسم الأكسدة بالميكرو-قوس (MAO) أو الأكسدة الكهربية البلازمية (PEO)—واحدة من عمليات هندسة الأسطح القليلة القادرة على تلبية هذه المتطلبات. إن فهم تصنيفاتها ومعاييرها أمرٌ أساسي لضمان اتساق الطلاء وموثوقيته وتوافقه مع المواد، خصوصًا عندما نُدمج العملية مع طرق تصنيع سابقة مثل صب الألومنيوم بالقوالب، أو صب الزنك بالقوالب، أو صب النحاس بالقوالب.

تُفصّل هذه المقالة معايير الأنودة القوسية، والأنواع الرئيسية المستخدمة عبر الصناعات، والاعتبارات التصنيعية اللازمة لضمان طلاءات عالية الأداء للتطبيقات الحديثة.

المعايير العالمية التي تحكم الأنودة القوسية

تُعد الأنودة القوسية أكثر تعقيدًا من الأنودة الكهروكيميائية التقليدية لأنها تتضمن تفريغات بلازمية موضعية. لذلك، تضع المعايير العالمية تعريفات صارمة لأداء الطلاء.

متطلبات ISO وASTM وMIL ومتطلبات قطاع السيارات

تركّز معايير ISO وASTM بقوة على التصاق الطلاء، والصلادة، والمسامية، وتجانس السماكة، وقوة العزل الكهربائي. يجب أن تلتزم طلاءات MAO ذات المستوى الجوي بمواصفات MIL التي تُعرّف استمرارية الطلاء واستقرار البنية المجهرية. وغالبًا ما تعتمد برامج السيارات مقاييس خاصة بالشركات المصنّعة (OEM)، بما في ذلك مقاومة دورات التآكل وتحمل الصدمات الحرارية.

التصنيف وأداء الطلاء

تُصنَّف الطلاءات عادةً حسب فئة الصلادة، ونطاق السماكة، وفئة قوة العزل الكهربائي، ومستوى المسامية. وتتأثر هذه العوامل بتركيب السبيكة ودرجة حرارة العملية والنمط الكهربائي. وبالنسبة لهياكل الإلكترونيات الاستهلاكية—بما في ذلك تلك المنتَجة عبر تعاونات مثل هياكل الألومنيوم المخصصة لهواوي—يضمن التصنيف اتساق العزل الكهربائي والمظهر التجميلي.

معايير قطاعات الطيران والإلكترونيات والطاقة

تتطلب الهياكل المقاومة للحرارة في مكوّنات الطيران وأغلفة البطاريات عالية الجهد في صناعة المركبات الكهربائية طلاءات MAO مُثبتة عبر اختبارات العزل الكهربائي ومقاومة التعب. وغالبًا ما تُدمج هذه العمليات مع خطوات تشطيب دقيقة مثل التشغيل باستخدام CNC أو النمذجة السريعة، خلال التطوير.

أنواع الأنودة القوسية والفروقات التقنية

الأكسدة بالميكرو-قوس التقليدية (MAO)

تعتمد MAO التقليدية على تفريغات عالية الطاقة تتشكل على أسطح الألومنيوم. وتنتج طبقات خزفية كثيفة بمقاومة ممتازة للاهتراء والتآكل.

الأكسدة الكهربية البلازمية (PEO)

تستخدم PEO أنماطًا كهربائية أكثر تحكمًا وأنظمة إلكتروليت متقدمة لتحقيق أسطح أنعم وأداء عزل كهربائي أعلى. ويشيع اعتمادها في مكوّنات الإدارة الحرارية للمركبات الكهربائية وقطاع الطيران.

الأنودة القوسية الصلبة مقابل الأنودة القوسية الزخرفية

تُعظّم الطلاءات القوسية الصلبة كلًا من الصلادة والسماكة، ما يجعلها مناسبة للتطبيقات الهيكلية أو عالية الإجهاد. أما النسخ الزخرفية فتركّز على جودة التشطيب والتحكم بالمسامية الدقيقة وثبات اللون، وغالبًا ما تُستخدم في الإلكترونيات الاستهلاكية وإكسسوارات التجميل.

MAO بدرجات حرارة عالية مقابل MAO بدرجات حرارة منخفضة

تنتج MAO ذات الحرارة العالية طبقات أكثر سماكة وصلادة، لكنها تتطلب طاقة أكبر وتولّد إجهادًا حراريًا أعلى. وتُفضّل MAO منخفضة الحرارة للمسبوكات رقيقة الجدار المصنوعة باستخدام سبيكة ADC12 أو ألومنيوم A380.

أنماط التغذية الكهربائية DC والنبضي والهجين

تتيح الأنماط النبضية والهجينة للمهندسين التحكم بسلوك الميكرو-قوس بدقة أكبر، ما يقلل عيوب الطلاء ويحسن التجانس على الهندسيات المعقدة.

توافق المواد والسلوك المعدني

أداء سبائك الألومنيوم

لا تتصرف جميع سبائك الألومنيوم بالطريقة نفسها تحت الأنودة القوسية. فالسبائك المصبوبة عالية السيليكون، مثل AlSi10Mg أو A380، تتطلب ضبطًا دقيقًا للتحكم في المسامية الدقيقة ومنع التشققات الحرارية. بينما تُنتج السبائك المشغولة عادةً طبقات خزفية أكثر نعومة وتجانسًا.

كما أن القائمة الواسعة من سبائك الألومنيوم المستخدمة في الصب بالقوالب تستلزم معايير طلاء مخصصة لكل تركيب.

اعتبارات الزنك والمغنيسيوم

تطبيق MAO على الزنك والمغنيسيوم ممكن تقنيًا لكنه أكثر تخصصًا. إذ توفر MAO على المغنيسيوم فوائد كبيرة من حيث نسبة القوة إلى الوزن، لكنها تتطلب إلكتروليتات خاصة.

تأثير محتوى السيليكون والموصلية والبنية السطحية

يؤثر محتوى السيليكون على سلوك البلازما. فالسبائك الأعلى سيليكونًا تتطلب جهودًا أعلى وغالبًا ما تنتج أسطحًا أكثر خشونة. كما تؤثر الموصلية الحرارية على تبديد الحرارة أثناء عملية التفريغ.

تدفق العملية ومعايير التصنيع الأساسية

المعالجة المسبقة وتنشيط السطح

تبدأ الأنودة القوسية الناجحة بمعالجة مسبقة دقيقة: إزالة الشحوم، والتنظيف القلوي، وتنشيط السطح. وغالبًا ما تُقذف أسطح الصب بحبيبات (bead blasting) أو تُشغّل تشغيلًا خفيفًا لتحسين التجانس.

تركيب الإلكتروليت والتحكم بحوض المعالجة

تؤثر كيمياء الإلكتروليت على جهد الانهيار وشدة البلازما. ويُعد الرصد اللحظي للحوض أمرًا حاسمًا لمنع حالات تفريغ غير مستقرة.

المعالجات اللاحقة والتشطيب النهائي

تأتي عمليات الإحكام والتلوين والتعديلات البُعدية بعد مرحلة الأكسدة الأساسية. وبالنسبة لمنتجات الصب بالقوالب، قد يشمل التشطيب إزالة الزوائد أو تشغيلًا لاحقًا، ثم تطبيق الأنودة لـالمسبوكات بالقوالب عندما تُستخدم أيضًا طرق طلاء تقليدية.

الدمج مع سير عمل الصب بالقوالب

تتوافق الأنودة القوسية بسلاسة مع عمليات الصب لدينا في Neway، بما في ذلك سبائك الزنك ومكوّنات الألومنيوم عالية الضغط. وتضمن خدمة الصب بالقوالب الشاملة لدينا اتساق الطلاء من النموذج الأولي إلى الإنتاج الكمي.

تطبيقات صناعية عبر القطاعات الرئيسية

الطيران

توفر المكوّنات المؤنودة قوسيًا أداء حاجز حراري، ومقاومة للاهتراء، وعزلًا كهربائيًا. وهي أساسية للهياكل، والدعامات، والمناطق القريبة من المحرك.

الإلكترونيات

تستفيد الأجهزة ذات الأغطية الحرارية أو الهياكل الزخرفية—المشابهة لتلك المطوّرة لهواوي—من مقاومة الخدش وثبات اللون.

السيارات

تعتمد أغلفة بطاريات المركبات الكهربائية، ومكوّنات المحرك، وملحقات منظومة نقل الحركة على MAO لتحسين الأداء الحراري. وتُبرز شراكات مثل حلول صب مكوّنات السيارات أهميتها.

المنتجات الاستهلاكية

تجعل جودة التشطيب الممتازة الأنودة القوسية جذابة للإلكترونيات الشخصية، والإكسسوارات الفاخرة، وقطع الهاردوير.

التحكم بالجودة والتحقق من الأداء

اختبارات صلادة الطلاء وسماكته

تضمن اختبارات الميكرو-صلادة وقياسات السماكة بالتيار الدوامي (eddy-current) الالتزام بفئات الأداء المحددة.

تحليل المسامية والبنية المجهرية

تؤكد فحوصات SEM والتقييم المعدني (metallographic) استمرارية الطلاء وتوزيع المسام.

اختبارات التآكل والاحتكاك والعزل الكهربائي

تخضع المكوّنات عالية القيمة لاختبارات الصدمة الحرارية ورذاذ الملح والتحقق من قوة العزل الكهربائي لضمان الموثوقية في التطبيقات القاسية.

كيف تعزز الأنودة القوسية دورة حياة المنتج

مزايا المتانة

تعزز طبقة الأكسيد الخزفية مقاومة الاهتراء بشكل كبير مقارنةً بالأنودة التقليدية.

اعتبارات الكفاءة والتكلفة

على الرغم من أن MAO أكثر استهلاكًا للطاقة، فإن متانتها تقلل احتياجات الصيانة أو الاستبدال على المدى الطويل.

ضمان قابلية التكرار

يضمن سلوك التفريغ المستقر وكيمياء الإلكتروليت المضبوطة والمعالجة المسبقة المحسّنة اتساق الطلاء عبر الدفعات.

الخلاصة

تجمع الأنودة القوسية بين فيزياء البلازما والكيمياء الكهربائية وهندسة المواد لتكوين طبقات شبيهة بالسيراميك تتفوق على الأنودة التقليدية. ومن خلال مواءمة تصنيفات العملية مع المعايير العالمية والتحكم الدقيق بالمعايير لكل سبيكة، تضمن Neway أداء طلاء موثوقًا عبر تطبيقات متعددة، بما في ذلك الطيران والإلكترونيات والسيارات والقطاعات الصناعية.