Enhancing Casting Precision: Comprehensive Material Testing for Consistency & Performance

Introduction

Precision in metal casting requires meticulous control over material properties. At Neway, our rigorous material testing procedures verify mechanical, chemical, and microstructural integrity, ensuring consistent, high-performance components. Our comprehensive evaluations help manufacturers confidently meet strict industry standards, reducing variability and ensuring reliability in demanding industries like automotive, aerospace, electronics, and industrial equipment manufacturing.

Importance of Comprehensive Material Testing

Comprehensive material testing directly impacts casting consistency, precision, and final performance. Systematic evaluation ensures adherence to stringent specifications and enhances reliability by:

Verifying compliance with international standards (ASTM, ISO, SAE).

Minimizing defects, including porosity, cracks, shrinkage, and inclusions.

Ensuring consistent mechanical properties (strength, ductility, hardness, fatigue resistance).

Confirming precise alloy compositions and phase distribution.

Providing accurate data and documentation for quality control and customer assurance.

Consistent material testing significantly reduces risks, improves component longevity, and ensures predictable casting quality.

Key Areas of Material Testing

At Neway, our comprehensive approach covers critical testing categories to optimize casting precision and reliability:

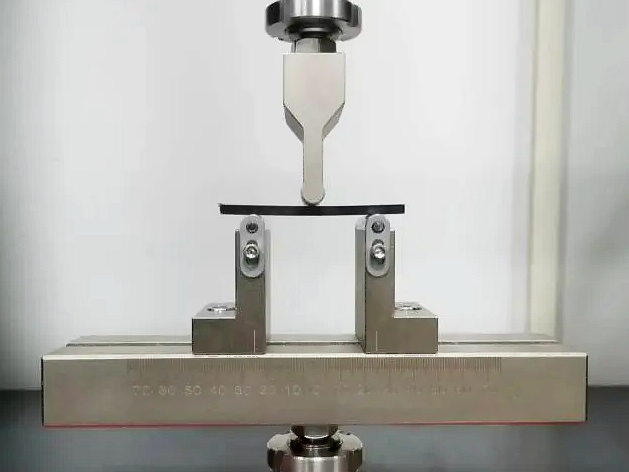

Mechanical Property Testing

Mechanical property testing measures critical performance parameters including:

Tensile Strength (ASTM E8/E8M): Ultimate strength verification, e.g., A380 aluminum alloy typically around 324 MPa.

Hardness Testing (ASTM E18/E10): Evaluating resistance to deformation (H13 steel typically 48–52 HRC; aluminum alloys like A356 around 70–90 HB).

Impact Testing (ASTM E23): Confirming toughness for dynamic applications, aluminum alloys such as AC8A typically exceeding 8–10 Joules.

Fatigue Testing (ASTM E466): Assessing durability under cyclic loading conditions (10^6 cycles or more).

Chemical Composition Analysis

Accurate chemical composition analysis ensures precise alloy performance and consistency:

Optical Emission Spectroscopy (OES): Measuring elemental composition within ±0.01% accuracy.

X-ray Fluorescence (XRF): Non-destructive verification, accurate to ±0.05%.

Wet Chemical Analysis: Precise verification of critical alloying elements compliant with standards such as ASTM E34 and E350.

Common alloys evaluated include aluminum (AlSi12), zinc (Zamak 3), copper (Brass 360), and specialty alloys (beryllium copper).

Metallographic Analysis

Metallographic analysis confirms microstructural quality, crucial for defect-free casting:

Grain Size Analysis (ASTM E112): Precise grain size control influencing mechanical properties.

Phase Distribution (ASTM E407): Evaluating critical phases, optimizing strength, toughness, and corrosion resistance.

Defect Detection (ASTM E3): Microscopic identification of porosity, inclusions, shrinkage, and cracking.

Dimensional and Geometric Inspection

Precision dimensional inspections ensure casting accuracy:

Coordinate Measuring Machines (CMM): Achieving accuracy within ±0.002 mm.

Optical Comparator: Confirming geometric conformity within ±0.01 mm tolerances.

Surface Roughness Inspection: Ensuring surface finish compliance (typically Ra ≤1.6 µm for precision components).

Compliance with International Standards

Neway’s material testing aligns strictly with recognized global standards:

Testing Method | Relevant Standards |

|---|---|

Mechanical Testing | ASTM E8/E8M, E18, E10, E23, E466 |

Chemical Composition | ASTM E34, E350 |

Metallographic Analysis | ASTM E112, E407, E3, E45 |

Dimensional Inspection | ISO 1101, ASME Y14.5 |

General Compliance | ISO 9001, SAE, AS9100, RoHS, REACH |

Strict adherence to these standards assures consistent casting precision and reliable component performance.

Advantages of Comprehensive Testing

Rigorous material testing provides significant manufacturing and operational benefits:

Reduced defect rates: Early defect detection cuts production rejects by up to 50%.

Improved reliability: Precise verification of mechanical and chemical properties ensures dependable component performance.

Enhanced compliance: Detailed documentation supports regulatory and customer specifications.

Consistent quality: Reproducible testing methods ensure minimal variability in high-volume manufacturing.

Cost-efficiency: Reduced material waste and fewer production disruptions lower overall manufacturing costs.

Case Study: Precision Testing for Aerospace Components

An aerospace manufacturer required comprehensive material verification for aluminum castings (AC7A alloy) used in structural components:

Mechanical Testing: Tensile strength verified at 300–320 MPa; hardness consistently between 80–90 HB.

Chemical Analysis: Alloy composition precisely matched ASTM B85 requirements, including controlled silicon (7–9%) and magnesium (0.2–0.6%) content.

Metallographic Examination: Grain size (ASTM 5–7) and defect levels (<0.5%) strictly compliant with aerospace specifications.

Dimensional Accuracy: CMM inspections confirmed dimensional accuracy within ±0.005 mm.

Result: Full compliance achieved, significantly increasing reliability, safety, and end-user confidence.

Why Choose Neway for Material Testing?

Advantage | Specification and Details |

|---|---|

Advanced Laboratory | Mechanical, chemical, metallographic testing labs |

Compliance Standards | ASTM, ISO, SAE, AS9100, RoHS, REACH compliant |

Material Expertise | Aluminum, zinc, copper, steel, specialty alloys |

Precision Measurement | ±0.01% accuracy (composition), ±0.002 mm (CMM) |

Comprehensive Reporting | Detailed certification and full traceability |

Conclusion

Comprehensive material testing ensures precision, consistency, and superior casting performance. At Neway, our extensive testing protocols guarantee reliable metal castings, meeting rigorous industry standards and customer requirements.

Partner with Neway for trusted, precise, and dependable casting solutions backed by thorough, professional material testing.

FAQs

What types of material tests are essential for ensuring casting precision?

How does comprehensive material testing enhance casting quality and reliability?

Which international standards guide material testing in metal casting?

What mechanical properties are most critical for high-performance castings?

How frequently should comprehensive material testing be conducted during production?