Beryllium Copper

Introduction to Beryllium Copper

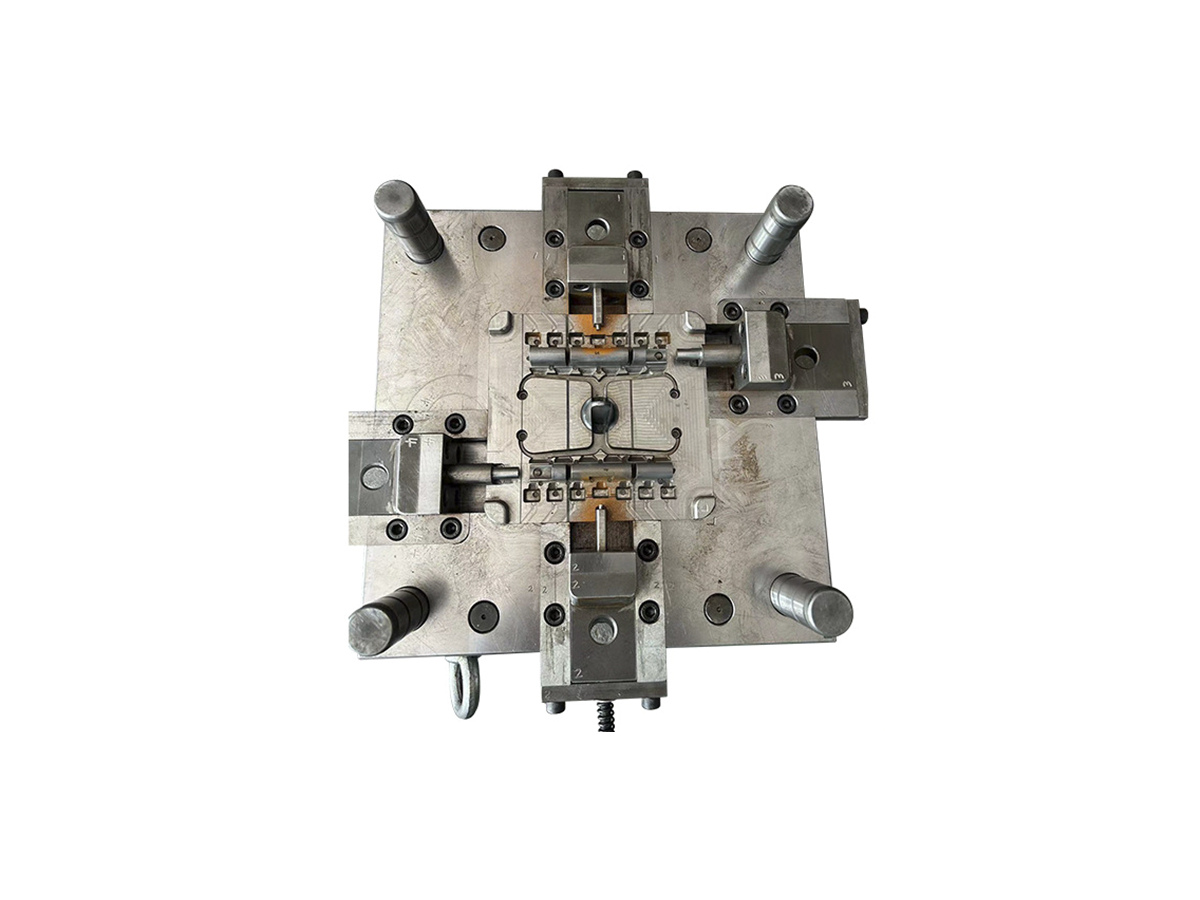

Beryllium copper (BeCu) is a high-performance copper-based alloy combining exceptional thermal conductivity, strength, and wear resistance. As one of the most advanced mold materials available, BeCu is extensively used in die casting and plastic injection tooling to improve cycle time, cooling performance, and dimensional accuracy.

At Neway Die Casting, Beryllium Copper is applied to tooling components that require rapid heat dissipation, tight tolerances, and enhanced mold durability, especially in high-precision aluminum and zinc alloy castings.

Beryllium Copper Chemical Composition (Typical C17200 Grade)

Element | Weight % | Function |

|---|---|---|

Copper (Cu) | ~97.75 | Base alloy, provides thermal/electrical conductivity |

Beryllium (Be) | 1.8–2.0 | Increases strength, hardenability, and thermal resistance |

Cobalt (Co), Nickel (Ni) | ≤ 0.5 | Enhances age-hardening response |

Other (Fe, Si, etc.) | ≤ 0.25 | Impurity control for conductivity and strength balance |

C17200 (Alloy 25) is the most common high-strength beryllium copper grade, conforming to ASTM B196 and RWMA Class 4 standards.

Physical Properties of Beryllium Copper

Property | Value & Unit |

|---|---|

Density | 8.26 g/cm³ |

Thermal Conductivity | 105–130 W/m·K |

Electrical Conductivity | 20–30 % IACS |

Coefficient of Thermal Expansion | 17.5 µm/m·°C |

Melting Range | 870–980 °C |

Specific Heat Capacity | ~380 J/kg·K |

Superior thermal conductivity enables BeCu molds to cool up to 5× faster than conventional steels, reducing cycle time significantly.

Mechanical Properties (Age-Hardened C17200)

Property | Value & Unit |

|---|---|

Tensile Strength | 1100–1400 MPa |

Yield Strength | 800–1200 MPa |

Hardness | 38–45 HRC |

Elongation | 2–8 % |

Modulus of Elasticity | ~128 GPa |

Fatigue Strength | ~310 MPa |

These values allow BeCu to withstand both thermal and mechanical stresses in precision casting environments.

Die Casting Tooling Advantages

BeCu is the material of choice in tooling applications where rapid thermal extraction and anti-soldering properties are critical:

Rapid cooling reduces cycle times by 20–40%

Resists aluminum soldering and thermal fatigue in core pins and inserts

High polishability makes it ideal for thin-wall or optical-grade mold surfaces

Better dimensional repeatability due to lower thermal distortion

At Neway’s tool and die workshop, BeCu is commonly used in:

Core pins, sleeve inserts, and gate bushings

High-performance prototype tooling for aluminum die casting

Shut-off and sealing surfaces in complex cavity systems

Common Applications

Beryllium copper excels in scenarios demanding both conductivity and mechanical strength:

Thin-wall electronic enclosures requiring dimensional precision

High-speed mold cycles for zinc and aluminum components

Molds with asymmetric cooling paths or localized hotspots

Die inserts and cores in high-pressure low-volume production

Sliding shut-off blocks or rotating cores with wear exposure

Machining Challenges and Solutions

BeCu is harder than most copper alloys and generates fine particulate dust, which must be handled with care:

Requires rigid tool setups and sharp carbide cutters

Low-speed, high-feed machining preferred to avoid surface hardening

Dust must be collected via wet systems or HEPA filtration due to beryllium toxicity

Neway ensures safe and precise BeCu CNC machining using:

Isolated machining stations with air control systems

Polishing and diamond finishing for optical-grade mold surfaces

Post-aging for dimensional stabilization before mold assembly

Surface Treatment Compatibility

Although BeCu is naturally corrosion-resistant, it also supports:

Chrome or nickel plating for enhanced wear life

EDM texturing for grip or matte finishes

Laser engraving without significant heat distortion

Polished BeCu inserts also serve well in mirror-finish casting applications without requiring coatings.

FAQs

What are the safety precautions for machining beryllium copper?

How does BeCu compare to H13 in mold cooling efficiency?

Can Beryllium Copper be used in high-tonnage production dies?

What is the expected mold cycle life for BeCu inserts?

Is BeCu suitable for plastic injection molds as well as die casting?