How To Choose the Tool and Die Materials

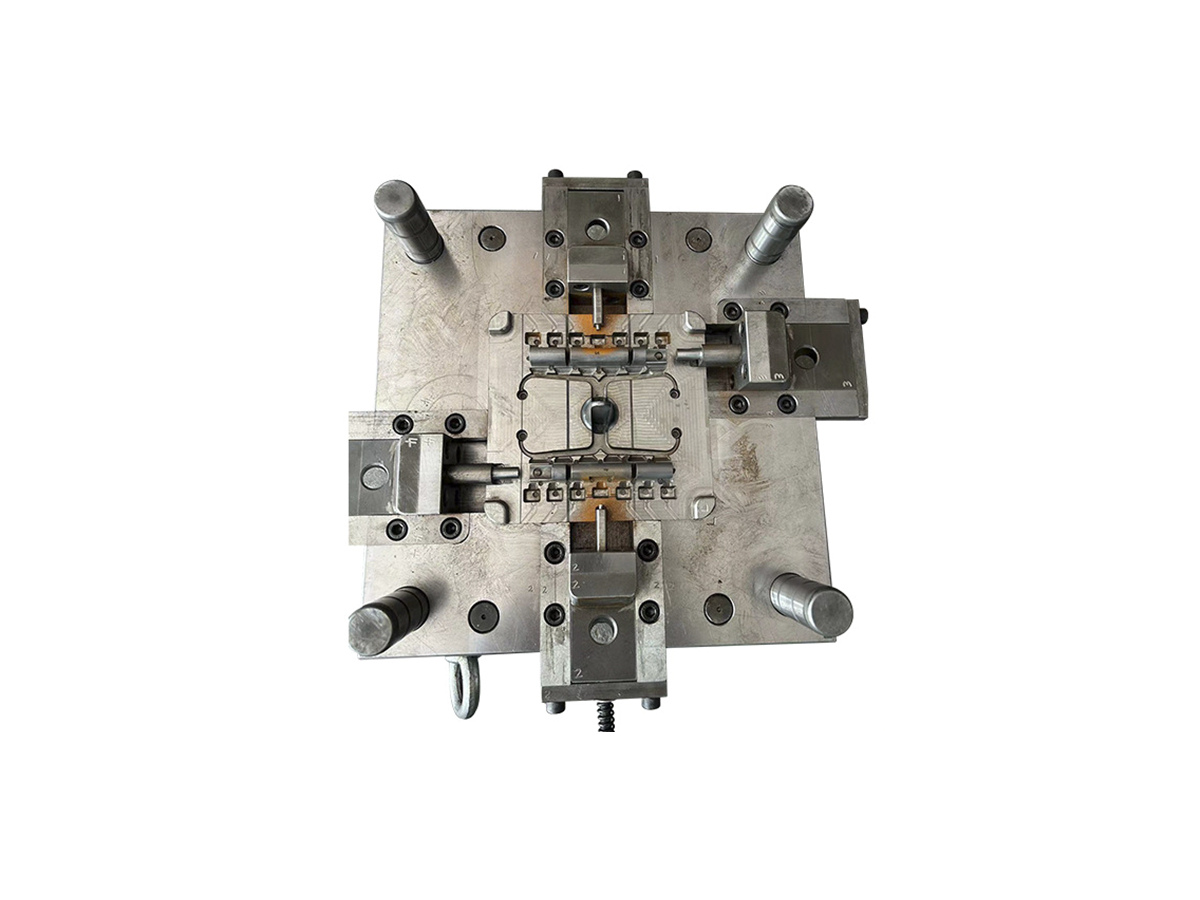

Tooling is the backbone of every precision casting or molding operation. Whether you're producing millions of die-cast parts or low-volume prototypes, selecting tool and die materials directly impacts production quality, tooling life, cycle times, and cost efficiency. At Neway, our tool and die making services are tailored to match your production volume, casting material, and performance expectations.

Tooling is the backbone of every precision casting or molding operation. Whether you're producing millions of die-cast parts or low-volume prototypes, selecting tool and die materials directly impacts production quality, tooling life, cycle times, and cost efficiency. At Neway, our tool and die making services are tailored to match your production volume, casting material, and performance expectations.

This guide outlines the critical factors influencing the selection of tool steels and specialty die materials, including thermal stability, wear resistance, toughness, machinability, and service life under real-world manufacturing conditions.

Why Tool and Die Material Selection Matters

Tool and die materials must endure mechanical stress, high temperatures, and chemical attacks during their operational lifespan. The wrong choice can lead to cracking, excessive wear, dimensional instability, and poor surface finish on cast components. Proper material selection ensures:

Dimensional consistency for tight-tolerance parts

Extended tool service life (100,000+ cycles in high-pressure aluminum die casting)

Minimized rework, downtime, and cost per part

Improved productivity and repeatability

Key Performance Requirements for Tool and Die Materials

Thermal Fatigue Resistance

In die casting, molten aluminum (~660°C), zinc (~420°C), or copper (~1085°C) is repeatedly injected into steel molds. Tooling must resist heat checking, thermal shock, and oxidation. For example, high-performance tools must maintain structural integrity over 100,000 injection cycles for aluminum, and at least 10,000 cycles for brass or bronze.

Wear Resistance and Hardness

Tool steels should possess a Rockwell hardness of 44–52 HRC (heat-treated) for aluminum die casting, or up to 60 HRC for cold work stamping dies. This ensures durability against erosive wear, cavitation, and molten metal flow.

Impact Toughness

Toughness protects against chipping and cracking during thermal cycling and mechanical impact. For die inserts, Charpy V-notch impact values greater than 20 J are often desirable, especially for geometrically complex molds.

Machinability and Surface Polishability

Precision tool cavities must be CNC-machined and polished to tight tolerances (±0.01 mm) and fine surface finishes (Ra < 0.4 µm for cosmetic parts). Materials with good machinability reduce tool build lead times and improve surface consistency.

Dimensional Stability

After heat treatment, low-distortion materials are critical to maintain the accuracy of complex cavities. Volumetric shrinkage below 0.3% post-hardening is typically acceptable for precision die tooling.

Overview of Common Tool and Die Materials

Neway offers a broad range of tool materials suitable for different manufacturing volumes, casting alloys, and operating conditions.

H13 Tool Steel

Hardened to: 44–52 HRC

Operating temperature: Up to 600°C

Thermal conductivity: ~24 W/m·K

Charpy impact energy: ~22–26 J

Applications: Aluminum die casting, zinc die casting, plastic injection molding

H13 is the most widely used hot work tool steel due to its excellent balance of strength, toughness, and heat resistance. It is the industry standard for aluminum and zinc casting molds.

P20 Tool Steel

Pre-hardened to: 28–32 HRC

Excellent machinability and polishability

Used for: Prototype molds, urethane casting, short-run tools

Operating temperature: Below 400°C

P20 is cost-effective for medium-hardness dies and injection molds where full hardness and thermal resistance are not essential.

D2 Tool Steel

Hardened to: 58–62 HRC

High chromium content (~12%) for wear resistance

Poor thermal fatigue and toughness

Ideal for: Cold work dies, blanking, and trim dies for thin sheet metals

D2 is perfect for high-abrasion applications but unsuitable for high-temperature casting or thermally cycled tools.

A2 Tool Steel

Hardened to: 56–60 HRC

Good dimensional stability and machinability

Moderate impact resistance

Used for: General-purpose dies, forming tools, and inserts

A2 bridges the gap between wear resistance and toughness in low-temperature applications.

Beryllium Copper (BeCu)

Hardness: 35–45 HRC

Thermal conductivity: Up to 110 W/m·K

Excellent polishability and corrosion resistance

Used for: Core pins, slides, and inserts in injection molding or zinc casting

BeCu is ideal for areas requiring rapid heat dissipation or fine surface finishes, particularly where cooling efficiency is critical.

Tool Steel S7

Hardened to: 54–56 HRC

Exceptional impact resistance

Toughness without brittleness

Applications: Trim dies, stamping tools, impact-intensive dies

S7 is used for tooling that faces repetitive impact and mechanical shock more than thermal cycling.

Tungsten Carbide

Hardness: >80 HRC

High compressive strength and wear resistance

Low toughness; brittle under shock

Used for: High-wear inserts, trimming dies, long-life shearing tools

Carbide is best for extremely high-wear environments and long-run trimming operations.

Inconel 718

Nickel-based superalloy

Tensile strength: Up to 1240 MPa at 700°C

Excellent creep and oxidation resistance

Used for: Copper alloy die casting, thermal core inserts

Inconel is necessary for hot-runner dies and high-temperature copper/brass applications where traditional steels fail prematurely.

How to Choose the Right Tool Material

The following criteria can guide material selection for die and mold design:

Parameter | Recommended Material |

|---|---|

Casting metal: Aluminum/Zinc | H13 or P20 (low volume) |

Casting metal: Copper/Brass | Inconel 718, BeCu inserts |

Tool life: <100,000 shots | P20, A2, S7 |

Tool life: >500,000 shots | H13, Carbide, Inconel |

Surface finish critical | BeCu, P20 |

Tight tolerances & polish | BeCu, A2 |

Budget-limited prototypes | P20 or pre-hardened steels |

Neway’s engineering team will analyze cycle temperature, thermal expansion, part geometry, and projected lifetime to select or recommend the most appropriate tool and die material for your project.

Integrated Tooling and Production at Neway

Neway provides complete tooling solutions from concept to production:

Design consultation with DFM and mold flow simulation

CNC and EDM machining with ±0.01 mm accuracy

Heat treatment and polishing

Tool integration with casting processes, including post-machining and finishing

Assembly and tool refurbishment services for multi-project reuse

Whether your project requires low-volume manufacturing or mass production, our tooling systems are engineered for reliability, accuracy, and cost control.

Conclusion

Choosing the right tool and die material is fundamental to successful, efficient, and long-lasting manufacturing. You can significantly reduce production risk and cost by aligning your tooling material with the casting alloy, cycle temperature, tool life, and part geometry. With deep expertise in tool steel and die making, Neway helps you streamline manufacturing from design through full-scale production.

For expert guidance or a quote on tooling solutions, contact Neway today.