What materials work best for copper and brass die casting?

What Materials Work Best for Copper and Brass Die Casting?

Material Selection in Copper-Based Alloy Die Casting

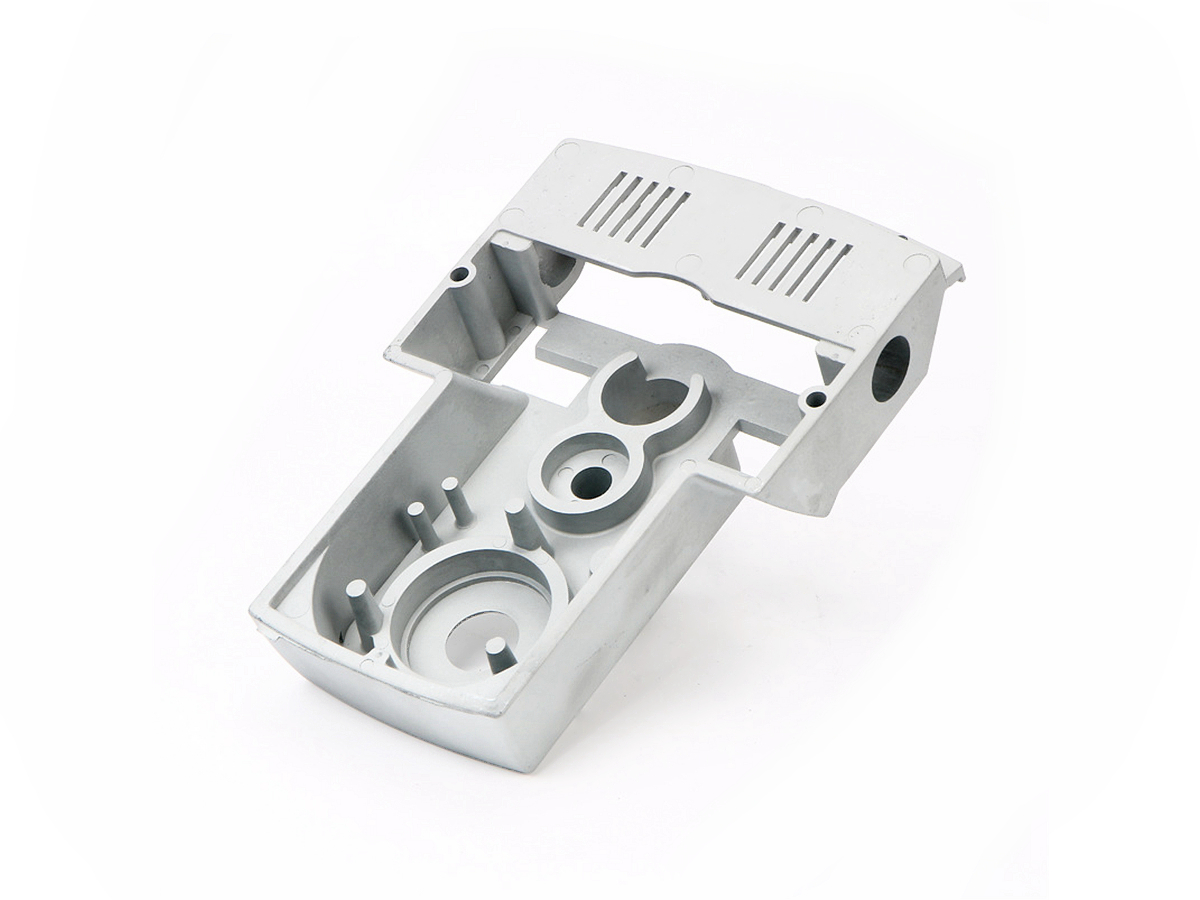

Copper and brass die casting require specialized alloys engineered for high strength, excellent corrosion resistance, and reliable castability. Due to the high melting point of copper alloys (up to 1200°C), the selected materials must also provide superior thermal conductivity, pressure tightness, and wear resistance. Neway offers a broad range of copper die casting materials designed to meet these demands across industries like plumbing, marine, automotive, and electrical hardware.

Top Copper and Brass Alloys for Die Casting

1. Brass 380

Brass 380 is one of the most commonly used casting brasses due to its excellent pressure tightness, corrosion resistance, and castability. It’s ideal for valve bodies, fittings, and pump housings.

2. Brass 464 (Naval Brass)

Brass 464 includes 1% tin for superior corrosion resistance in saltwater environments, making it perfect for marine hardware, propellers, and hull fittings.

3. Aluminum Bronze C95400

C95400 offers very high strength, good shock resistance, and outstanding corrosion performance, even in seawater or chemically aggressive environments. It’s commonly used for bushings, gears, and hydraulic fittings.

4. Leaded Red Brass C83600

C83600, also known as ounce metal, is a high-castability alloy often used for faucets, valves, and decorative hardware. It offers good machinability and moderate strength.

5. Beryllium Copper

Beryllium copper is not typically used for die cast parts but is often used in die inserts due to its outstanding thermal conductivity and wear resistance when casting copper-based alloys.

Recommended Casting and Tooling Solutions for Copper and Brass Projects

To achieve optimal casting results, Neway offers:

Copper Alloy Die Casting

Copper Die Casting: Comprehensive services for brass, bronze, and specialty copper alloys.

Material Selection Guidance

Copper Alloys: View detailed alloy properties for brass, aluminum bronze, and red brass grades.

Precision Tooling and Heat Management

Tool and Die Making: Durable dies for high-temperature copper alloy casting, including specialized inserts for thermal control.

Our one-stop service provides full support for alloy selection, tooling design, casting execution, and part finishing to meet demanding industrial performance and quality standards.