Durable and Corrosion-Resistant Aluminum Die Cast Parts for Marine Applications

Marine environments present some of the most challenging conditions for mechanical components. Exposure to saltwater, UV radiation, and varying temperatures leads to accelerated corrosion, metal fatigue, and long-term degradation of materials. In this setting, aluminum die casting has emerged as a reliable and cost-effective solution for manufacturing durable, corrosion-resistant components used across marine vessels, offshore systems, and coastal installations.

Marine environments present some of the most challenging conditions for mechanical components. Exposure to saltwater, UV radiation, and varying temperatures leads to accelerated corrosion, metal fatigue, and long-term degradation of materials. In this setting, aluminum die casting has emerged as a reliable and cost-effective solution for manufacturing durable, corrosion-resistant components used across marine vessels, offshore systems, and coastal installations.

At Neway, we produce custom aluminum die cast parts engineered specifically for marine applications. Our castings combine strength, lightweight performance, and superior resistance to saltwater corrosion, making them ideal for environments where reliability is paramount.

Why Aluminum Die Casting Is Ideal for Marine Environments

Aluminum alloys used in die casting provide excellent strength-to-weight ratios while offering intrinsic corrosion resistance. Combined with high-pressure die casting, they enable the production of parts with complex geometries and tight tolerances, suited for both structural and non-structural marine components.

Key Performance Advantages

Density of ~2.7 g/cm³ reduces total part weight by up to 60% compared to steel

Tensile strength up to 310 MPa with A356-T6 heat treatment

General tolerances to ±0.05 mm; critical surfaces to ±0.02 mm

Salt spray resistance exceeding 1000 hours with anodizing or powder coating

Operating temperature range from -40°C to 150°C without deformation or embrittlement

These properties reduce maintenance cycles, improve vessel fuel efficiency, and ensure longer service life under continuous exposure to harsh conditions.

Typical Marine Applications for Aluminum Die Cast Parts

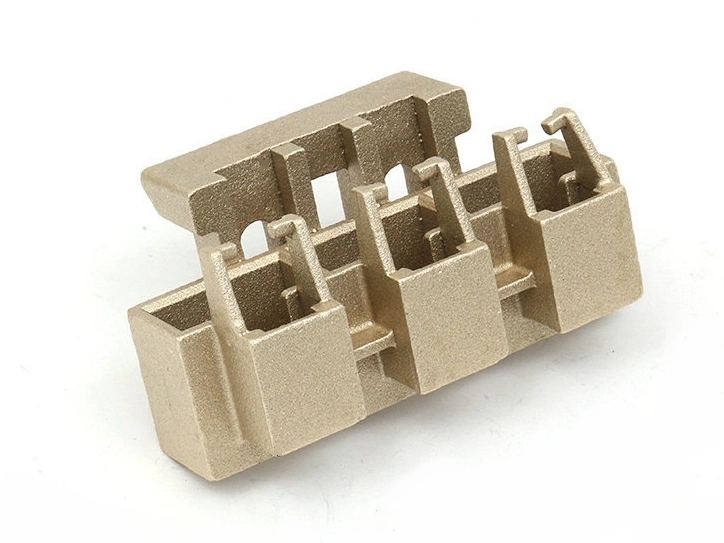

Aluminum die casting supports a wide range of parts used on and around watercraft and marine infrastructure.

Application Area | Component Examples | Functional Requirements |

|---|---|---|

Hull and Deck Systems | Housings, frames, access covers | Corrosion resistance, weight reduction, form integrity |

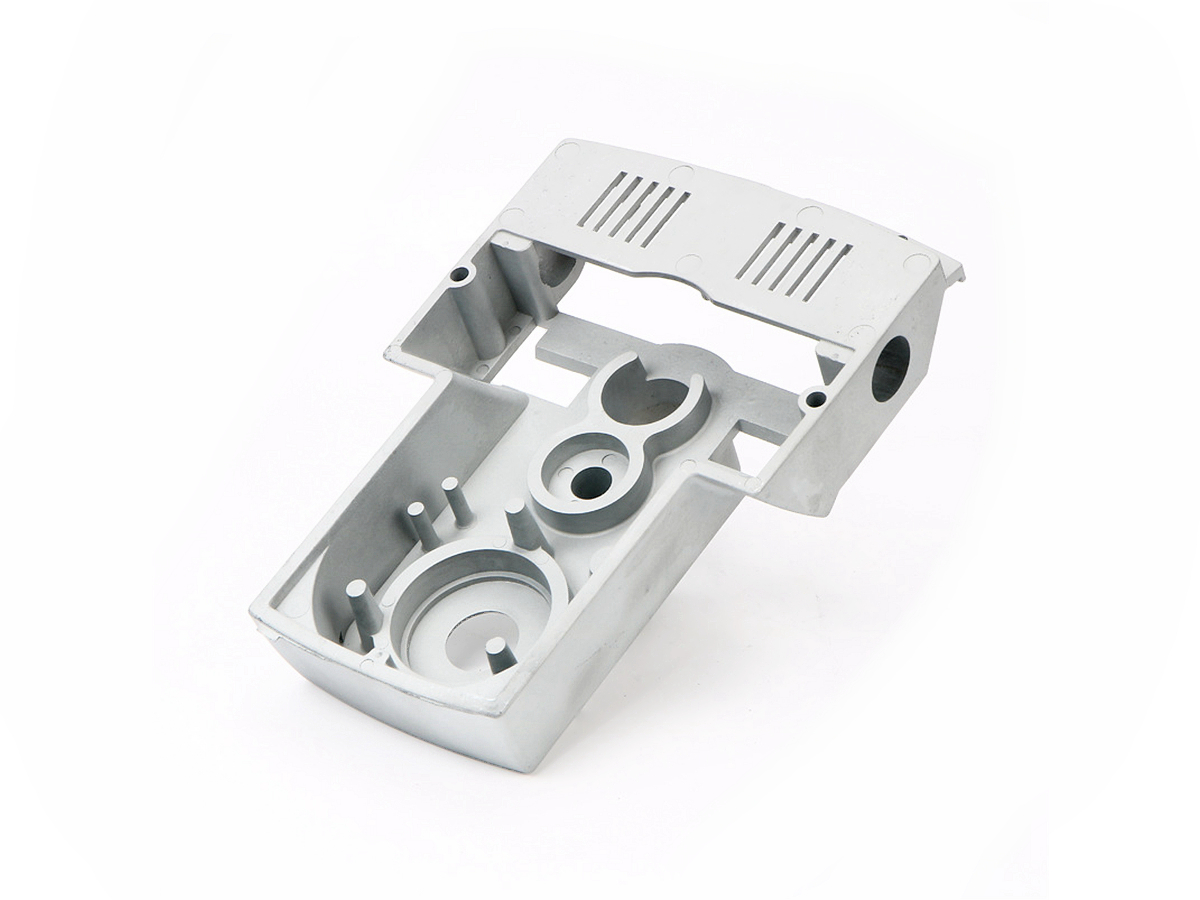

Electrical Systems | Junction boxes, enclosures, conduit supports | Waterproofing, EMI shielding, dimensional consistency |

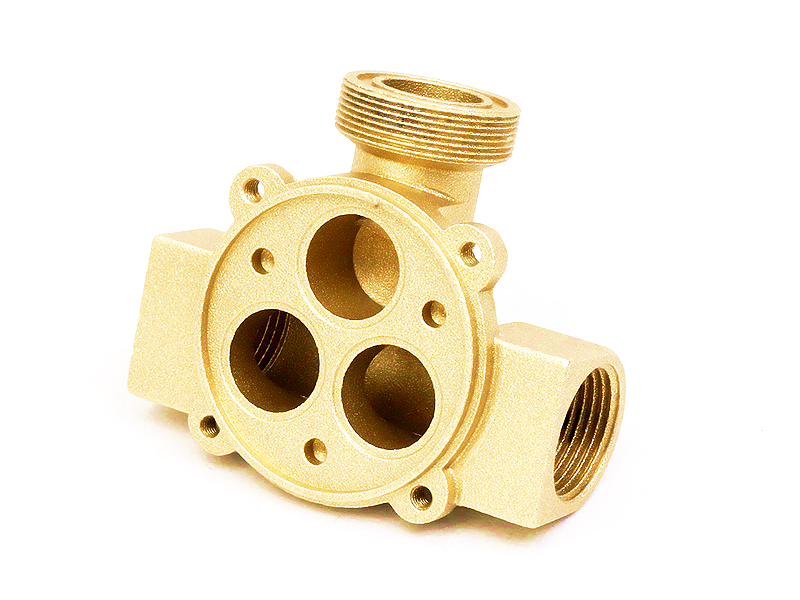

Propulsion Components | Pump casings, bearing carriers, filter housings | Pressure resistance, heat dissipation, fatigue strength |

Navigation and Control | Sensor mounts, gear actuators, light fixtures | Vibration resistance, corrosion protection, finish durability |

Offshore Infrastructure | Mounting brackets, handrail supports, clamps | UV and salt spray resistance, mechanical reliability |

Marine-Grade Aluminum Alloys

Neway uses marine-optimized aluminum alloys that comply with standards such as ASTM B85, ISO 3522, and MIL-A-8625.

Alloy | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Marine Uses |

|---|---|---|---|---|

A360 | 2.65 | ~290 | High | Waterproof enclosures, control systems |

A356-T6 | 2.68 | 290–310 | Excellent | Propulsion, pumps, heat exchangers |

AlSi12 | 2.66 | 250–280 | Very High | Navigation brackets, sensor housings |

A356 and AlSi12 are particularly suited for saltwater contact and structural use, offering long-term resistance to pitting and galvanic corrosion.

Corrosion Resistance and Surface Protection

While aluminum alloys are naturally resistant to corrosion, marine-grade parts often require additional protection due to constant salt exposure. Neway provides in-house surface treatments to enhance corrosion performance:

Anodizing: Type II and III anodizing per MIL-A-8625 for pitting resistance and dielectric strength

Powder coating: 60–100 µm thickness; adheres to ISO 2812 for solvent resistance

Painting: Marine-grade topcoats for UV protection and aesthetic durability

Tumbling and sand blasting: Achieve uniform Ra ≤ 3.2 µm for protective finish prep

These finishes meet or exceed ISO 9227 salt spray test (1000+ hours) and ASTM B117 corrosion test standards.

Precision, Strength, and Machinability

Die cast parts for marine systems must offer structural integrity and precision mating with other mechanical systems, especially in propulsion and control applications.

Tolerances of ±0.05 mm on general features

Flatness ≤ 0.08 mm over surfaces up to 250 mm

Machinability: excellent for adding threads, sealing surfaces, and complex cutouts

Fatigue resistance: validated to cyclic loads exceeding 50 MPa over 10⁶ cycles in A356-T6

Pressure-tightness: capable of withstanding 10 bar hydrostatic pressure when required

We also provide CNC post-machining for critical mounting and sealing interfaces.

Tooling, Production Scalability, and Lead Times

Neway supports tool and die making and high-efficiency production across both low-volume manufacturing and mass production programs.

Die steel: H13 tool steel with corrosion-resistant inserts for long life

Tool life: 75,000–150,000 shots for aluminum die molds

Cycle time: 30–70 seconds, depending on part complexity

Tooling lead time: 4–6 weeks

Production volumes: from pilot batches to 500,000+ parts annually

We also offer rapid prototyping services to support initial design validation for marine systems.

Case Study: Offshore Navigation Beacon Housing

A marine safety equipment supplier required corrosion-resistant housing for offshore LED navigation beacons. Design criteria included:

Service life >10 years in saltwater

Surface finish: powder-coated and UV-resistant

Weight under 1.2 kg

Dimensional flatness <0.1 mm

Operating temperature range: -20°C to +80°C

Neway used A360 aluminum alloy with a multi-cavity mold and integrated cooling features. Post-casting powder coating ensured 1200-hour salt spray resistance. Finished assemblies passed all drop, impact, and weathering tests according to IEC 60529 and EN 60945.

Why Marine OEMs Choose Neway

Neway provides end-to-end support for marine casting projects, including:

Design support for corrosion-optimized geometries

Certified ISO 9001:2015 production and marine-grade material traceability

In-house machining, coating, and assembly

Fatigue, salt spray, pressure, and drop testing

Flexible logistics and export support for coastal and offshore markets

We help clients reduce part weight, extend service life, and accelerate time to market with high-quality, corrosion-resistant die-cast parts.

Conclusion

In harsh marine environments, aluminum die cast components deliver strength, dimensional accuracy, and long-term corrosion resistance. With advanced alloy selection, protective finishing, and precision manufacturing, Neway ensures your parts remain reliable under water, salt, sun, and time. Whether for onboard systems, offshore structures, or shoreline installations, our aluminum solutions offer durability where it matters most.

To start your marine casting project, contact Neway today.

FAQs

What aluminum alloys are best suited for saltwater marine environments?

How does aluminum die casting compare to stainless steel in corrosion resistance?

Can marine die cast parts be sealed to IP65 or higher standards?

What surface coatings provide the best protection in coastal conditions?

What testing standards apply to aluminum parts used in marine systems?