High-Strength Copper Die Casting for Efficient Automotive Cooling Systems

Automotive cooling systems rely on components with high thermal conductivity, mechanical durability, and reliable form factor repeatability. As vehicles become increasingly electrified and engine thermal loads continue to rise, copper die casting has emerged as a preferred method for manufacturing heat exchangers, cooling plates, and liquid routing modules. Copper’s superior heat transfer properties and structural integrity under thermal cycling make it ideal for demanding automotive environments.

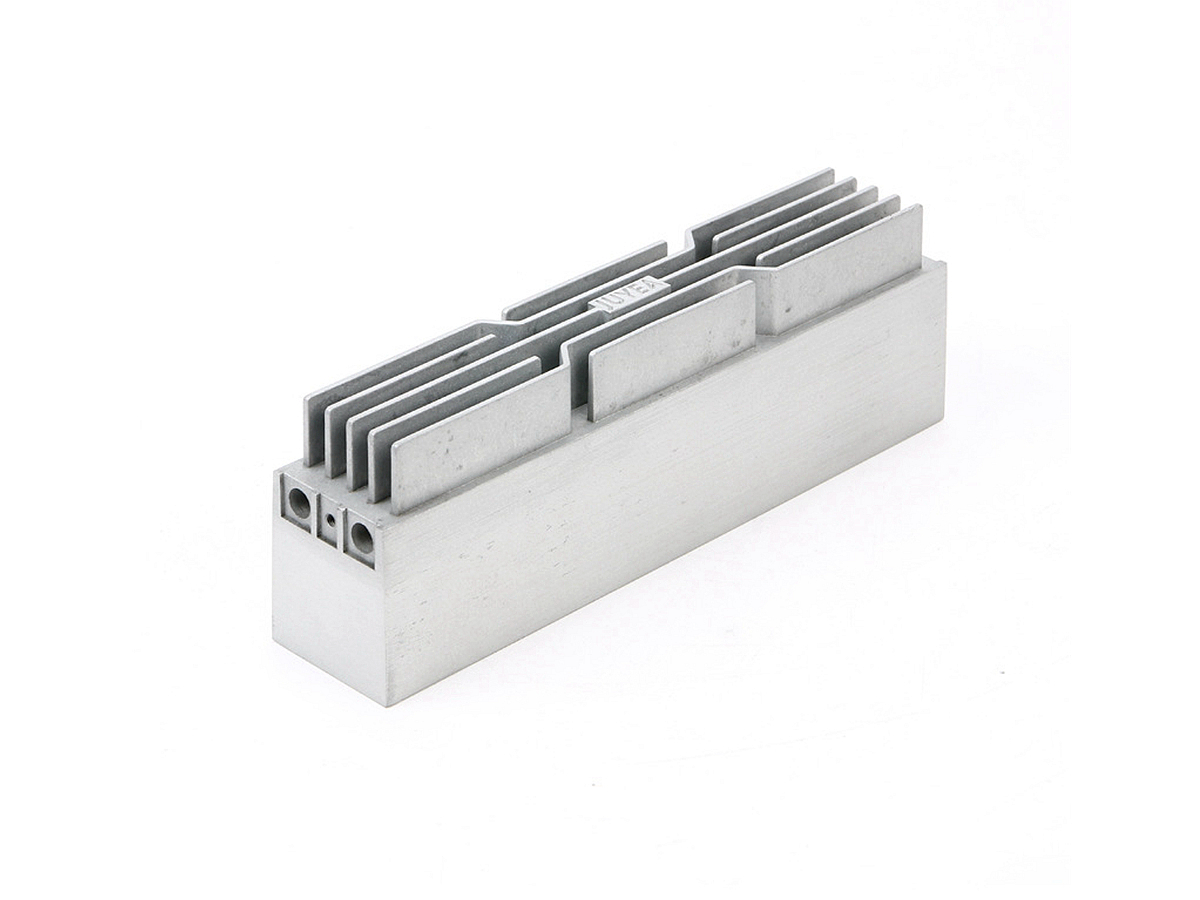

Neway provides copper die casting services for advanced cooling system components used in internal combustion engine (ICE), hybrid, and battery electric vehicles (BEVs). Our precision die casting capabilities ensure efficient thermal transfer, minimal porosity, and consistent tolerances required for large-scale automotive production.

Why Copper Is Ideal for Automotive Cooling Applications

Copper’s thermal conductivity, nearly four times greater than aluminum's, makes it an ideal material for heat dissipation in compact spaces. Automotive cooling supports rapid heat extraction from engines, transmissions, power electronics, and battery systems. Copper alloys also offer natural corrosion resistance and excellent mechanical strength under vibration and thermal fatigue.

Key Advantages

Thermal conductivity: 300–400 W/m·K

Tensile strength: 200–400 MPa, depending on the alloy

Pressure resistance: up to 3.5 MPa in cooling housings

Dimensional tolerance: ±0.02 mm in critical mating or sealing surfaces

Service temperature: -40°C to 200°C in automotive environments

Copper die casting allows integration of thin walls, sealing flanges, internal cooling channels, and mounting brackets, reducing part count and improving assembly efficiency.

Common Copper Die Cast Components in Automotive Cooling

Automotive cooling systems increasingly require integrated, space-saving designs. Copper die casting is ideal for producing multifunctional components with built-in heat transfer and structural features.

Component Type | Application Examples | Key Functional Requirements |

|---|---|---|

Cooling Plates | EV battery packs, power inverters, IGBT modules | High heat flux management, flatness, corrosion resistance |

Radiator Headers | Engine radiator tanks, transmission oil coolers | Thin wall casting, pressure durability, tube sealing interfaces |

Liquid Routing Modules | Battery chillers, electronic valve bodies | Sealing surfaces, pressure resistance, internal flow paths |

Pump Housings | Electric water pumps, oil recirculators | Thermal load resistance, dimensional repeatability |

Heat Exchanger Shells | AC condenser/evaporator modules, refrigerant distributors | Uniform channel geometry, vibration durability |

Copper Alloys Used in Automotive Die Casting

Neway utilizes several copper and copper-based alloys that conform to ISO 1634-1 and ASTM B148 standards for automotive-grade casting.

Alloy | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Best Use Cases |

|---|---|---|---|

C18200 | ~320 | ~340 | Cooling plates, pump housings, header tanks |

C17500 | ~180 | ~600 (age-hardened) | Fatigue-prone parts, electric drive cooling enclosures |

CuZn37 | ~120 | ~450 | Mid-strength routing modules and brackets |

CuNi10Fe1 | ~40 | ~400 | Corrosion-resistant modules in marine or chemical EVs |

C18200 (chromium copper) is most often used for high-thermal-conductivity automotive parts that require strong mechanical performance and solder compatibility.

Precision and Surface Finish Requirements

Automotive cooling parts demand stringent tolerances to maintain sealing integrity, ensure consistent coolant flow, and prevent vibration-induced wear.

Wall thickness: 1.2–3.0 mm for fluid walls or contact zones

Flatness: ≤ 0.03 mm on cooling plates for thermal interface materials

Hole location accuracy: ±0.02 mm for press-fit fittings or threaded ports

Surface roughness: Ra ≤ 1.6 µm for sealing surfaces and gasket interfaces

Porosity level: <0.5% verified by vacuum leak testing or X-ray inspection

Neway utilizes CNC machining for sealing grooves, mounting threads, or O-ring channels, ensuring ready-to-assemble components.

Surface Treatments and Environmental Protection

To extend service life in high-humidity and temperature-variable environments, Neway offers several post-processing and coating options for copper die cast parts:

Electroplating: tin or nickel plating to improve corrosion resistance and electrical contact integrity

Powder coating: up to 100 µm protective coatings for exposed cooling modules

Painting: color-coding for assembly ID or safety standards compliance

Tumbling and polishing: for smooth exterior finish or improved flow dynamics

Assembly: integration of O-rings, fasteners, valves, or thermal pads

All finishing processes conform to RoHS and REACH regulations, with available salt spray testing per ISO 9227 or ASTM B117 standards.

Tooling and Production Capabilities

Neway’s tool and die making division is optimized for high-complexity automotive tooling, including multi-cavity and slide-intensive designs.

Die material: H13 tool steel with wear-resistant inserts

Die life: 100,000–300,000 cycles for copper-based alloys

Tooling lead time: 4–6 weeks including full DFM and mold flow simulation

Part cycle time: 30–45 seconds depending on size and geometry

Rapid prototyping: short-run tooling or hybrid soft-tooling available

Neway supports both low-volume launches and mass production for tier-1 automotive suppliers.

Case Study: Copper Cooling Plate for High-Voltage EV Inverter

An electric vehicle manufacturer required a thin, high-precision copper plate for inverter cooling. Specifications included:

Target conductivity ≥ 300 W/m·K

Flatness ≤ 0.03 mm over 200 mm × 140 mm surface

Wall thickness of 1.6 mm, with integrated inlet/outlet bosses

2.5 MPa pressure resistance

Compatibility with thermal interface materials (TIM) and epoxy coatings

Annual demand: 250,000 units

Neway used C18200 alloy and a slide-cored 2-cavity die design. After casting, the parts were CNC machined for groove depth control and plated with 10 µm nickel. The components passed burst testing, thermal performance benchmarks, and warpage tests post-TIM application.

Why Automotive OEMs and Tier Suppliers Trust Neway

Neway offers vertically integrated copper die casting solutions tailored to automotive cooling system manufacturers:

ISO 9001:2015-certified quality management

Full in-house control from tooling to final assembly

Support for PPAP documentation, IMDS submissions, and process FMEA

Automotive-qualified materials and finishing options

Design-for-manufacturability feedback to improve part performance and reduce cost

We deliver precision copper components ready for direct assembly in thermal management modules, radiators, pump housings, and heat shields.

Conclusion

As the automotive industry demands more efficient and durable cooling systems for combustion, hybrid, and electric platforms, copper die casting offers an unmatched combination of thermal performance, design flexibility, and manufacturing precision. At Neway, we leverage advanced copper alloys and high-precision casting technologies to deliver the parts that keep next-generation vehicles cool, safe, and efficient.

To get started on your automotive cooling system project, contact Neway today.

FAQs

Which copper alloys provide the best conductivity for automotive cooling systems?

How does copper die casting compare to aluminum for heat exchanger components?

What sealing tolerances are achievable for cooling modules with integrated ports?

What finishing options prevent copper corrosion in glycol or refrigerant environments?

What is the typical cycle time and lead time for automotive cooling plate production?