Casting vs Forging: Which Process Lowers Production Costs

Introduction

Metal forming processes play a pivotal role in determining both the performance and cost efficiency of manufactured components. Among the most widely used methods, casting and forging stand out for their versatility and broad application across industries. However, these two processes differ significantly in tooling costs, material utilization, mechanical properties, and production efficiency.

For manufacturers seeking to reduce production costs while maintaining product quality, selecting the optimal process is critical. This article provides an engineering-driven comparison of casting versus forging, analyzing which process offers greater cost advantages across various production scenarios and design requirements.

Understanding Casting and Forging Processes

Selecting the optimal forming process requires a clear understanding of how casting and forging fundamentally differ. Each method offers distinct cost structures, material performance, and production capabilities. Engineers must evaluate these differences against their specific design and production goals.

Overview of Metal Casting

Metal casting is a manufacturing process where molten metal is poured into a mold cavity, solidifying into the desired shape. It supports a wide variety of alloys, including aluminum, zinc, copper, and specialty alloys.

Common casting processes include:

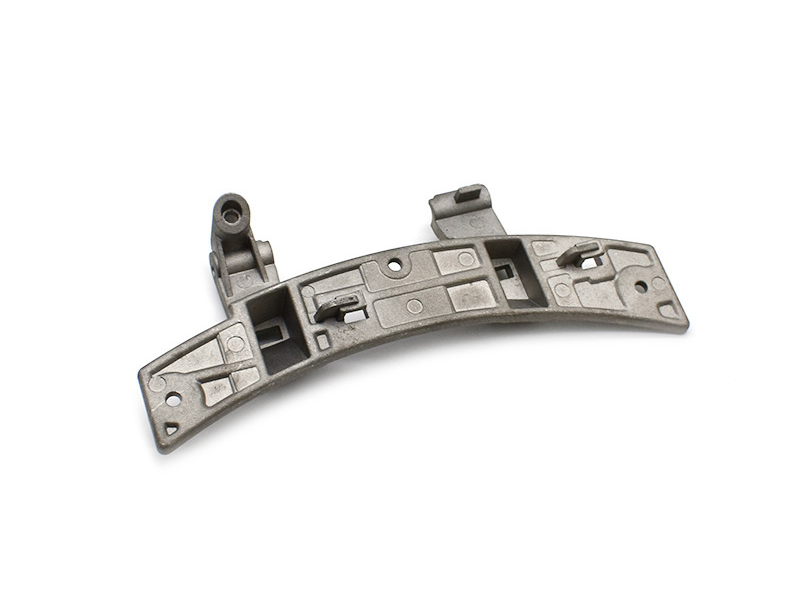

High Pressure Die Casting (HPDC): Ideal for high-volume production of thin-walled components with excellent surface finish and tight tolerances, used extensively in automotive and electronics.

Gravity Casting: Suitable for medium-complexity parts where moderate tooling investment and good mechanical properties are needed.

Sand Casting: Versatile for large or complex geometries, prototypes, or low-volume manufacturing.

Investment Casting: Delivers high precision for complex geometries, commonly used in aerospace and medical applications.

Casting offers unmatched design flexibility, allowing for intricate geometries, integrated features, and near-net shapes that reduce machining needs. However, it typically involves more extensive post-processing to achieve final specifications.

Overview of Metal Forging

Forging is a process in which metal is plastically deformed under compressive forces to shape it into the desired form. It refines the metal’s grain structure, enhancing mechanical strength and fatigue resistance.

Primary forging methods include:

Open-Die Forging: Used for large components such as shafts or disks.

Closed-Die (Impression-Die) Forging: Creates near-net shape parts for critical applications such as automotive suspension components, aerospace structural parts, and gears.

Cold Forging: Suitable for high-strength fasteners and precision components.

Forging generally achieves superior mechanical properties with minimal internal defects. Parts typically require less machining and offer greater fatigue life, making them ideal for high-performance, load-bearing applications. However, forging is limited in its ability to produce highly complex or integrated geometries and often incurs higher tooling and setup costs.

Cost Drivers in Casting vs Forging

To select the most cost-effective process, engineers must analyze the key factors that influence total production cost. Casting and forging exhibit different cost dynamics based on tooling, material usage, cycle times, and post-processing requirements. Below is a detailed comparison of these critical drivers.

Tooling and Setup Costs

Tooling investment is often the largest upfront cost in both casting and forging.

Casting typically involves permanent molds or dies. High-pressure die casting (HPDC) requires advanced tooling, costing $20,000 to $100,000+, depending on complexity. Gravity casting and sand casting patterns are significantly cheaper, especially for low-volume manufacturing or prototyping.

Forging tooling, particularly for closed-die forging, is highly engineered to withstand extreme compressive forces, often matching or exceeding HPDC costs. Additionally, the setup process involves precise temperature control and specialized equipment, increasing initial capital outlay.

For short runs or variable demand, casting is typically more cost-effective. For long-term, high-volume production of critical load-bearing parts, forging tooling costs can be amortized over large production volumes.

Material Utilization and Yield

Material yield and scrap rates directly impact production cost.

Forging generally achieves superior material utilization. The controlled deformation process minimizes waste, and forged parts exhibit dense, defect-free microstructures.

Casting, especially with complex geometries, involves gating systems, risers, and trimming, resulting in higher scrap rates. However, optimized gravity casting and low-pressure die casting techniques have significantly improved yield in recent years.

When raw material costs are high (such as copper alloys), forging offers distinct cost advantages through material savings.

Cycle Time and Production Speed

Production speed influences labor cost and machine utilization.

HPDC is one of the fastest metal forming processes, with cycle times measured in seconds, making it ideal for high-volume consumer products and automotive components.

Forging, especially hot forging, involves longer heating cycles and press strokes, leading to lower throughput compared to HPDC. Open-die forging for large parts can take several minutes per piece.

Sand casting and investment casting are relatively slow, with casting, cooling, and finishing times spanning hours to days, depending on part size.

For time-sensitive projects or markets driven by fast production cycles, casting—particularly HPDC—tends to lower per-part costs through superior throughput.

Post-Processing Requirements

Post-processing significantly influences total cost.

Casting often requires post-machining to achieve tight tolerances, and surface treatments such as anodizing, powder coating, or painting to enhance corrosion resistance and aesthetics. For example, premium surface finishes are essential in industries like consumer electronics.

Forging delivers superior as-formed tolerances and surface quality, often requiring less machining. This advantage reduces secondary operation costs, particularly valuable in applications where net shape or near-net shape is achievable.

In scenarios where parts must undergo extensive finishing—such as high-polish visible housings—casting may incur higher total cost. For functional parts requiring minimal finishing, forging typically provides an economical solution.

Mechanical Properties and Performance vs Cost

While cost is a primary consideration, mechanical performance must align with application requirements. Casting and forging produce components with distinct structural characteristics that influence both initial production cost and lifecycle value.

Structural Integrity and Strength

Forging refines the grain structure through plastic deformation, producing parts with superior tensile strength, impact resistance, and fatigue life. Components such as aerospace structural parts, automotive suspension arms, and gear blanks are typically forged to maximize performance.

In contrast, casting involves solidification from a molten state, which can introduce porosity, shrinkage defects, and microsegregation. However, advanced casting techniques mitigate these risks:

High-pressure die casting (HPDC) achieves high density for thin-walled complex parts.

Low-pressure die casting delivers improved metallurgical quality for structural components.

Investment casting offers exceptional surface quality and fine detail while maintaining reasonable mechanical strength.

For non-critical components, cast parts often provide sufficient strength at a lower cost. For highly stressed applications, forging justifies its higher initial expense through superior durability.

Design Flexibility

Casting clearly outperforms forging in design freedom.

Complex geometries with integrated features—such as consumer electronics housings, pump housings, or intricate heat sinks—are most efficiently produced via casting.

Internal channels, undercuts, and optimized topology are challenging or impossible to forge without complex multi-stage operations and secondary machining.

Forging excels for simpler, solid geometries where mechanical properties are paramount—shafts, rings, disks, and connecting rods.

Tolerances and Surface Finish

Surface finish and dimensional accuracy are key contributors to post-processing costs.

HPDC can achieve surface roughness as low as Ra 1.6–3.2 μm with minimal machining required—ideal for automotive engine components and cosmetic applications.

Sand casting produces rougher surfaces and larger tolerances, requiring significant post-processing for precision parts.

Forging delivers an excellent surface finish with minimal flash, and tolerances approaching ±0.2 mm for precision closed-die forging. In many applications, this reduces or eliminates secondary machining, driving down total cost.

For products where cosmetic appearance or complex geometry dominates (consumer electronics, architectural hardware), casting is often the more cost-effective choice. For components where strength-to-weight ratio and fatigue life are critical, forging delivers better value despite higher upfront tooling costs.

Process Selection Guidelines to Minimize Production Costs

The choice between casting and forging must align with project-specific priorities: production volume, part complexity, material performance, and total cost of ownership (TCO). A structured evaluation helps engineers select the process that optimizes both manufacturing cost and end-use value.

Cost Optimization for Low vs High Volume Production

Production volume plays a decisive role in process selection.

For low-volume manufacturing—custom parts, prototypes, and specialty components—casting typically offers the most economical solution. Processes such as sand casting or gravity casting require minimal tooling investment, making them ideal for runs of 10 to 5,000 units.

For high-volume production (50,000+ units/year), HPDC achieves unbeatable per-part cost through rapid cycle times and low material waste.

Forging becomes most competitive in medium to high volumes of high-performance parts, where its superior mechanical properties reduce lifecycle costs. In automotive, forged drivetrain components often outperform cast alternatives in TCO.

Part Geometry and Function

Geometry and function dictate process feasibility.

Complex, integrated shapes with thin walls, fine features, or internal passages strongly favor casting. Examples include consumer electronics housings and LED heat sinks.

Load-bearing, fatigue-critical components—such as aerospace brackets, connecting rods, or gear blanks—benefit from the superior grain flow and strength of forging.

Where both processes are technically viable, casting usually offers lower initial and per-part cost, while forging offers superior long-term reliability for mission-critical applications.

Total Cost of Ownership (TCO) Considerations

TCO encompasses all costs associated with a part over its lifecycle: tooling, production, quality control, warranty claims, and service life.

Forging commands higher tooling and unit costs but can deliver parts with longer service life and lower field failure rates—reducing warranty and maintenance expenses in sectors like aerospace and energy.

Casting, particularly HPDC, excels in high-throughput consumer products where minimizing per-part cost and time to market is critical.

Factors such as yield, scrap rates, inspection requirements, and post-processing must all be considered to accurately model TCO.

In many cases, working with an experienced manufacturing partner such as Neway Die Casting helps optimize this balance through design-for-manufacturability (DFM) insights.

Case Study: Comparative Example

Criteria | Casting | Forging |

|---|---|---|

Tooling Cost | Medium to High | High |

Per-Part Cost | Low (HPDC) / Medium (Sand) | Medium |

Design Complexity | High | Limited |

Mechanical Strength | Medium to High | Very High |

Surface Finish | Good (HPDC), varies by process | Excellent |

Production Speed | Very High (HPDC), varies | Medium |

Best for | Complex parts, large runs | Critical load-bearing parts |