CNC Machining vs Casting: Choosing the Best Manufacturing Method

Introduction

Selecting the optimal manufacturing method is a critical decision in modern product development. CNC machining and metal casting are two of the most widely used processes, each offering unique advantages in cost, precision, design flexibility, and production efficiency. However, their suitability depends heavily on factors such as part geometry, production volume, material performance, and lead time.

This article provides an engineering-driven comparison of CNC machining and casting. It will guide manufacturers through key considerations—helping them choose the best method to optimize production costs, meet design requirements, and ensure long-term product quality.

Understanding CNC Machining and Casting Processes

To select the most suitable manufacturing method, it is essential to understand how CNC machining and casting fundamentally differ. Each offers unique capabilities that influence design flexibility, material performance, cost, and production scalability.

What Is CNC Machining

CNC machining is a subtractive manufacturing process where computer-controlled tools precisely remove material from a solid workpiece. This method includes milling, turning, drilling, grinding, and other operations, allowing manufacturers to achieve extremely high tolerances and surface finishes.

CNC machining supports a broad range of materials, including metals (such as aluminum, steel, and titanium), plastics, and composites. It is widely used for:

Aerospace components requiring exceptional precision

Medical devices

Mold bases and tooling

Low-volume production or prototypes where design changes are frequent

Since no casting mold is required, CNC machining excels in low-volume manufacturing and high-mix product environments.

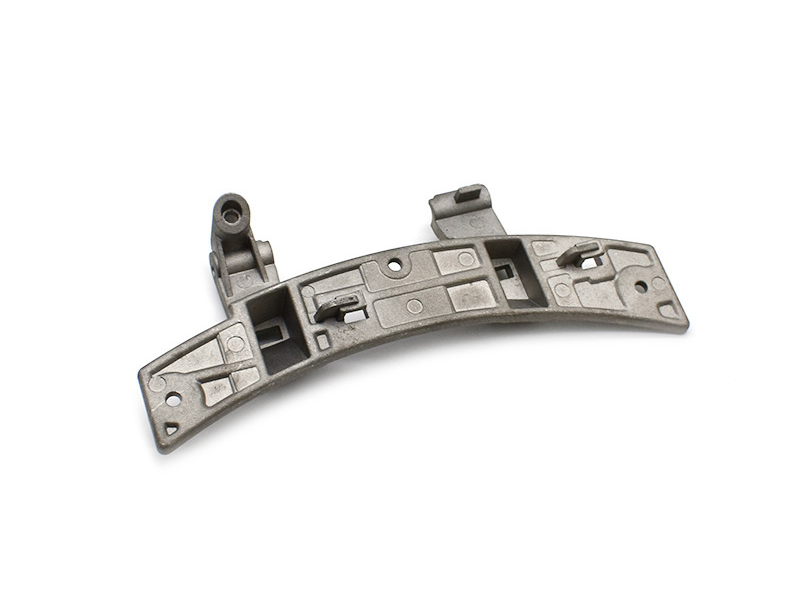

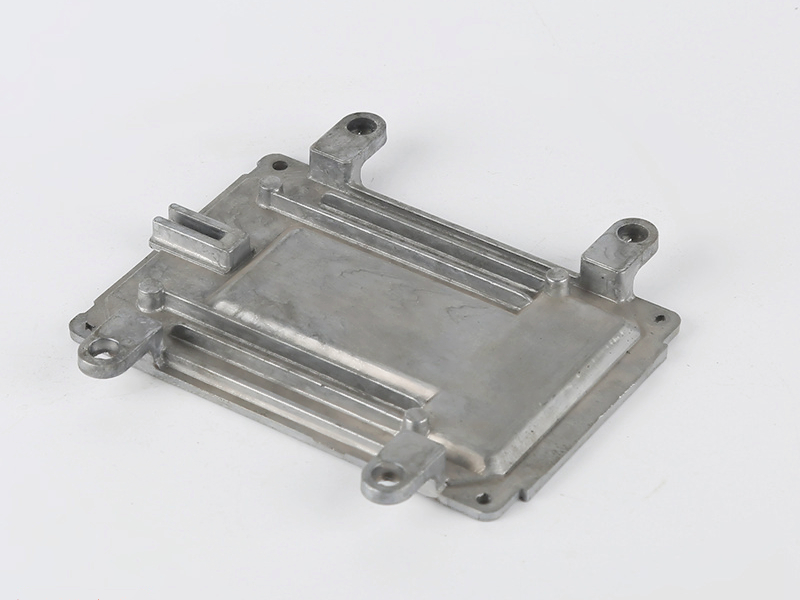

What Is Metal Casting

Metal casting is a forming process where molten metal is poured into a mold and allowed to solidify into the desired shape. It enables the production of near-net shape parts, significantly reducing material waste.

Common casting methods include:

High Pressure Die Casting (HPDC): Ideal for thin-walled, complex parts with high production volumes.

Gravity Casting: Suitable for medium-volume production with moderate tooling investment.

Sand Casting: Flexible and economical for large components and prototypes.

Investment Casting: Enables production of highly detailed parts with excellent surface finish.

Metal casting is frequently used for:

Casting offers unparalleled design freedom, enabling complex internal geometries and integrated structures not feasible with machining alone.

Cost Comparison: CNC Machining vs Casting

Selecting the most cost-effective process requires an in-depth understanding of how CNC machining and casting differ in terms of tooling, material usage, production cost per part, and post-processing. Each process has specific cost drivers that must be weighed against project goals.

Tooling and Setup Costs

CNC machining requires minimal tooling. A set of cutting tools and workholding fixtures is sufficient, making it ideal for low-volume manufacturing, prototyping, or parts with frequent design changes. No expensive molds or dies are needed—setup costs are low and lead times are short.

In contrast, metal casting often requires substantial tooling investment:

HPDC molds can range from $20,000 to over $100,000, depending on complexity.

Gravity casting and sand casting tooling are less expensive, but still represent a notable upfront cost.

Therefore, for low-volume or one-off parts, CNC machining typically offers a lower overall setup cost.

Per-Part Production Cost

Per-part production cost trends depend heavily on batch size.

CNC machining involves long cycle times, especially for complex geometries, which drives up labor and machine costs. For small runs, this is acceptable, but for large batches, machining becomes cost-prohibitive.

Casting—especially HPDC—achieves extremely low per-part cost at scale, as cycle times are measured in seconds and molds can produce thousands to millions of parts before wear-out.

In general:

Low-volume = CNC is more economical

High volume = Casting dominates in cost efficiency

Material Utilization and Waste

CNC machining is a subtractive process—removing material to create the final shape. This often results in significant waste, especially for parts with large internal cavities or complex geometries. The cost of wasted material must be considered, especially with expensive alloys like titanium or copper alloys.

Casting is an additive process in that the part is formed directly to near-net shape. This maximizes material utilization and minimizes waste. Techniques like low-pressure die casting further improve yield and reduce scrap.

Post-Processing Costs

CNC machining produces high-precision parts with excellent surface finish directly from the machine. Many components require minimal or no post-processing.

In contrast, cast parts often require:

Post machining to meet tight tolerances

Surface treatments such as anodizing, powder coating, or painting to achieve the desired aesthetic and corrosion performance

For example, premium surface finishes are often required for consumer electronics housings.

Thus, while casting offers lower per-part cost, post-processing expenses must be considered when comparing total production cost.

Performance and Design Considerations

Beyond cost, engineers must consider how CNC machining and casting compare in terms of precision, mechanical properties, design flexibility, and consistency. The right process must align not just with budgets but also with functional and quality requirements.

Tolerances and Surface Finish

CNC machining delivers industry-leading precision.

Typical tolerances are ±0.01 mm or better, making it the method of choice for critical aerospace components, medical implants, and precision tooling.

Surface finishes from CNC milling or turning can achieve Ra values of 0.4–1.6 μm without additional polishing.

By contrast, casting processes—especially high pressure die casting (HPDC)—have improved significantly in precision and surface quality.

HPDC parts can achieve tolerances of ±0.1–0.2 mm and excellent surface finishes, suitable for automotive engine components and consumer electronics housings.

Investment casting offers near-net shape parts with fine detail and smoother surfaces compared to sand casting.

Thus, for ultra-precision parts, CNC machining remains superior. For medium-precision requirements, modern casting techniques provide cost-effective alternatives.

Design Complexity

Casting enables exceptional design freedom.

Complex geometries, internal cavities, thin walls, and integrated features can be easily achieved through casting processes like HPDC or gravity casting.

Investment casting enables intricate designs with minimal machining.

In contrast, CNC machining excels at simple to moderately complex geometries where high precision is critical. However, CNC struggles with internal features that require multi-axis setups or specialized tooling, driving up costs for intricate designs.

For parts like LED heat sinks or intricate pump housings, casting is often the only feasible solution.

Mechanical Properties

The mechanical properties of CNC-machined parts are superior because the base material’s integrity remains intact.

High-strength alloys retain their original metallurgical properties, providing excellent fatigue resistance and durability.

CNC machining is ideal for parts subjected to high mechanical loads or cyclic stresses.

Casting can achieve good mechanical properties, especially with optimized high-strength aluminum alloys or copper alloys.

Low-pressure die casting improves material density and reduces porosity.

However, cast parts may exhibit lower fatigue resistance compared to machined counterparts due to micro-defects introduced during solidification.

For structural applications or mission-critical components, CNC machining offers an undeniable advantage in mechanical performance.

Repeatability and Quality Consistency

CNC machining delivers excellent repeatability, with computer-controlled processes ensuring part-to-part consistency across production runs.

Precision inspection and coordinate measuring machines (CMM) validate dimensional accuracy.

Casting repeatability depends heavily on mold quality, process control, and foundry expertise.

HPDC offers high consistency for large-scale production, but variations can occur due to mold wear and process fluctuations.

For industries requiring strict quality standards—such as aerospace, medical, or high-end automotive—CNC machining remains the preferred choice.

When to Choose CNC Machining vs Casting

Selecting between CNC machining and casting depends on a combination of production volume, part complexity, lead time, and total cost of ownership (TCO). This section provides clear guidelines for choosing the most cost-effective method based on real-world manufacturing considerations.

Volume and Lead Time

Production volume is often the primary factor influencing process selection.

For low-volume production or prototypes (1 to 1,000 units), CNC machining offers flexibility and fast turnaround. There is no need for expensive tooling, making it ideal for short lead times or rapidly evolving designs.

For high-volume production (10,000+ units), casting—especially high-pressure die casting (HPDC)—is far more economical. Once tooling is amortized, per-part costs drop dramatically, making casting the preferred choice for mass production.

Low-volume manufacturing often benefits from hybrid approaches, where prototypes are CNC-machined and production transitions to casting once designs are validated.

Part Geometry and Function

Geometry and functional requirements strongly influence process choice.

Casting excels at producing complex, hollow, or highly integrated parts—such as consumer electronics housings or LED heat sinks—that would be prohibitively expensive or impossible to machine.

CNC machining is ideal for high-precision, load-bearing components requiring tight tolerances, such as aerospace brackets, mold inserts, or medical devices.

For mixed-requirement assemblies, engineers often combine processes—for example, casting the housing and CNC machining critical interfaces.

Total Cost of Ownership (TCO)

TCO includes all expenses associated with a part: tooling, production, inspection, post-processing, maintenance, and lifecycle performance.

Casting delivers lower per-part costs for high-volume products but incurs higher upfront tooling and inspection requirements to manage quality consistency.

CNC machining incurs higher per-part costs but offers superior repeatability and reduces quality-related risk for critical components.

Factors such as yield rates, scrap, tool life, and warranty risk should all be modeled when evaluating TCO. For highly regulated industries—such as aerospace or medical—CNC machining often proves more cost-effective when lifecycle risk is considered.

Case Study: Comparative Example

Criteria | CNC Machining | Casting |

|---|---|---|

Tooling Cost | Low | Medium to High |

Per-Part Cost | High (small batch) | Low (high batch) |

Tolerances | Very High (±0.01 mm) | Medium to High (HPDC ±0.1–0.2 mm) |

Design Flexibility | Medium | Very High |

Surface Finish | Excellent (Ra ≤ 1.6 μm) | Good to Excellent (HPDC, Investment) |

Lead Time | Short | Medium |

Best for | High-precision parts, small series | Complex shapes, mass production |

By applying this structured decision matrix, engineers can confidently select the most suitable manufacturing method for their project’s technical and business objectives.