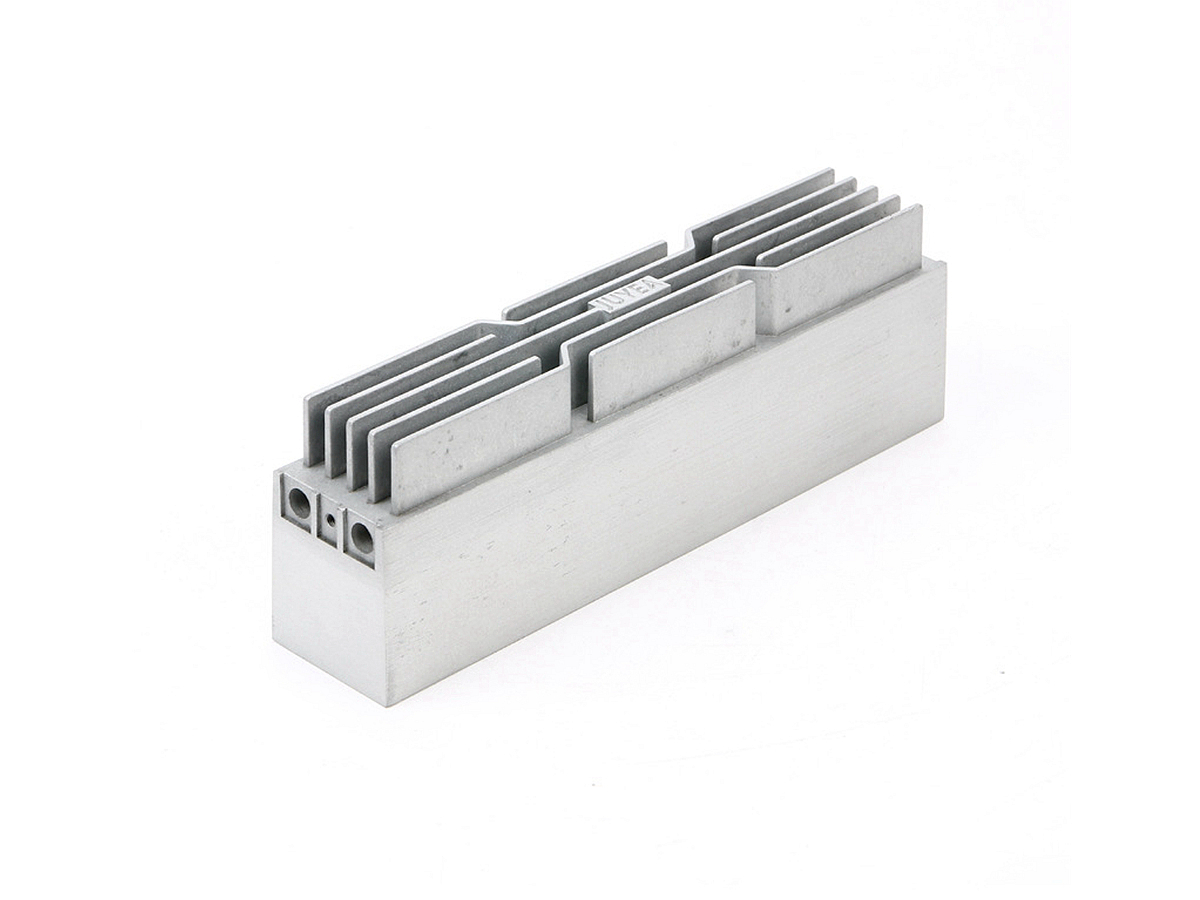

Custom Die Cast Aluminum Heat Sinks for Efficient Thermal Management

As electronics, power equipment, and LED systems evolve to become more compact and powerful, the challenge of thermal regulation becomes increasingly critical. Heat sinks play an essential role by drawing heat away from high-temperature components and dispersing it efficiently. Among various heat sink fabrication methods, aluminum die casting is an effective solution for combining thermal performance with design flexibility and manufacturing scalability.

As electronics, power equipment, and LED systems evolve to become more compact and powerful, the challenge of thermal regulation becomes increasingly critical. Heat sinks play an essential role by drawing heat away from high-temperature components and dispersing it efficiently. Among various heat sink fabrication methods, aluminum die casting is an effective solution for combining thermal performance with design flexibility and manufacturing scalability.

At Neway, we specialize in aluminum die casting services for custom heat sinks used in high-performance applications. Our solutions provide optimized thermal conductivity, structural precision, and production efficiency.

Why Aluminum Die Casting is Ideal for Heat Sinks

Aluminum alloys are widely used in heat sinks due to their lightweight, corrosion resistance, and high thermal conductivity. The die casting process enhances this by enabling the mass production of complex geometries such as integrated cooling fins, mounting tabs, and enclosed flow paths.

Performance Advantages

Thermal conductivity between 120 and 160 W/m·K for standard alloys

Net-shape or near-net-shape part formation for reduced secondary operations

General dimensional tolerances within ±0.05 mm; critical tolerances to ±0.02 mm

Heat sink wall thickness as low as 1.2 mm with reinforced structural design

Typical production cycle time of 30 to 60 seconds per part

These characteristics allow for tight-fitting assemblies, consistent thermal dissipation, and cost-effective high-volume production.

Typical Applications of Die Cast Aluminum Heat Sinks

Custom aluminum heat sinks are essential in various industries where compact, passive, or forced convection cooling is required. Some common uses include:

Industry | Applications | Key Requirements |

|---|---|---|

Consumer Electronics | Laptop CPUs, amplifiers, gaming consoles | Compact form factor, high heat dissipation |

Automotive | EV control units, motor drives, inverters | Thermal shock resistance, vibration durability |

Industrial Equipment | Motor controllers, PLCs, variable speed drives | High power density, long lifecycle reliability |

LED Lighting | High-lumen LED lamps, panel lights | Passive cooling, corrosion resistance |

Telecommunications | Base station cooling plates, signal routers | Lightweight, EMI shielding, airflow optimization |

Aluminum Alloys Used for Die Cast Heat Sinks

Neway casts heat sinks using aluminum alloys that balance thermal conductivity, fluidity for casting, and structural durability. These alloys conform to standards such as ASTM B85 and ISO 3522.

Alloy | Density (g/cm³) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Common Use Cases |

|---|---|---|---|---|

A380 | 2.74 | 96–105 | ~317 | Consumer electronics, enclosures with fins |

A360 | 2.65 | 120–130 | ~290 | Automotive and industrial thermal plates |

AlSi12 | 2.66 | 140–160 | 250–280 | LED light housings, precision cooling devices |

AlSi12 offers superior thermal performance and fluidity, making it ideal for dense fin structures and large surface area designs.

Heat Sink Design Capabilities

Neway supports advanced Design for Manufacturability services to assist engineers in developing heat sink geometries that optimize cooling performance.

Fin spacing: minimum 1.5 mm

Fin thickness: minimum 1.0 mm

Pin-fin, radial-fin, and cross-cut fin arrays supported

Base thickness tolerance: ±0.02 mm

Surface flatness: within 0.08 mm over 200 mm length

Surface roughness: Ra ≤ 2.0 µm achievable with tumbling

We provide mold flow simulation and thermal modeling to verify performance before tool development.

Surface Treatment and Post-Processing

To enhance heat sink efficiency and durability, Neway offers a range of post-processing and finishing services:

CNC machining: for mounting interfaces, countersinks, and precision slots

Anodizing: increases emissivity and provides corrosion resistance; Type II black anodizing is widely used for passive radiation enhancement

Powder coating: offers protection against UV and abrasion with 60–100 µm thickness

Sand blasting: improves thermal contact area and appearance

Painting: for color branding or protective topcoats

All finishes comply with ISO 9227 salt spray test and ISO 2409 cross-hatch adhesion standards.

Tooling and Production Capacity

Neway’s tool and die making team delivers fast, efficient solutions for thermal management components.

Die materials: H13 tool steel with optimized cooling channels

Tool life: 75,000–150,000 cycles for aluminum alloys

Cycle time: 30–60 seconds per part, depending on design complexity

Production volumes: suitable for low-volume manufacturing and full mass production

We also offer rapid prototyping with soft tooling or 3D-printed patterns to verify form, fit, and thermal performance during early development.

Case Study: Heat Sink for Industrial Control Cabinet

A manufacturer of programmable logic controllers (PLCs) requires a precision-cast aluminum heat sink for a high-power module with these requirements:

Conductivity ≥130 W/m·K

Base thickness tolerance ±0.02 mm

Maximum unit weight: 800 g

Surface finish: black anodized for heat radiation

Finned surface area: ≥400 cm²

Neway used A360 alloy with a 2-cavity mold and high-precision cooling line placement. After anodizing and dimensional verification, thermal testing showed a 12°C drop compared to the previously extruded model. The customer reported a 22% cost savings and improved heat uniformity in field deployment.

Why Engineers Choose Neway for Heat Sink Manufacturing

Neway offers end-to-end project execution and support, from thermal design consultation to finished part delivery:

In-house thermal simulation and flow optimization

Integrated casting, machining, coating, and assembly

Certified ISO 9001:2015 quality control and traceability

Lean supply chain for flexible production volumes

Expertise across consumer, automotive, LED, and industrial sectors

Our team works closely with your engineers to meet your technical targets, timelines, and product cost goals.

Conclusion

Die-cast aluminum heat sinks provide an optimal solution for thermal management in compact, performance-driven systems. They offer the benefits of high conductivity, integrated design, and repeatable quality at scale. Whether you're developing smart electronics, industrial automation controllers, or LED lighting modules, Neway delivers precision thermal components that meet your exact specifications.

Contact Neway for a tailored quote and expert guidance to start your custom heat sink project.