How to Effectively Reduce Unit Costs in Aluminum Die Casting Parts

Introduction: The Challenge of Cost Efficiency in Aluminum Die Casting

Aluminum die casting remains one of the most efficient methods for producing complex metal components at scale, but maintaining competitive pricing requires manufacturers to consistently evaluate and reduce unit costs. Rising raw material prices, increased energy consumption, and tighter tolerances in modern part designs add pressure to optimize every stage of the production process.

This blog explores practical methods that aluminum die casting manufacturers and sourcing engineers can implement to significantly reduce unit costs. From tooling design optimization to aluminum alloy selection and post-processing minimization, every detail in the workflow matters.

Optimize Tooling Design to Extend Mold Life and Cut Cost Per Shot

Tooling accounts for a substantial portion of die casting setup costs. Optimizing die and mold designs can significantly increase tooling life, reduce cycle time, and improve dimensional consistency. A well-engineered tool, utilizing high-performance materials like H13 tool steel or Tungsten Carbide, can withstand high injection pressures and thermal cycling, minimizing premature wear.

Incorporating thermal regulation channels, vacuum venting, and uniform wall thicknesses in the tool design directly correlates to lower maintenance downtime and fewer rejected parts. Collaboration between design and manufacturing teams during the prototyping phase ensures that the final tool aligns with cost-saving goals.

Select Cost-Efficient Aluminum Alloys Without Compromising Quality

The choice of aluminum alloy impacts not only the mechanical performance but also the casting behavior and scrap rates. Using alloys like A383 (ADC12) or A380 provides a good balance of fluidity, corrosion resistance, and dimensional stability, while reducing porosity and improving yield rates in high-pressure die casting (HPDC).

For specific applications requiring enhanced strength or thermal conductivity, alloys like AC8A or A356 can be used without expensive secondary reinforcements. Carefully aligning the alloy grade with the part’s function prevents over-engineering and lowers both material and energy costs during production.

Reduce Cycle Time by Streamlining Injection Parameters

Cycle time directly influences unit cost. By optimizing injection velocity, holding pressure, and mold temperature through advanced process controls, manufacturers can reduce cycle durations while maintaining quality. Use of automated monitoring systems to adjust parameters in real-time allows for more consistent output and minimizes overcasting or underfilling defects.

Integrating automated robotic part ejection and trimming systems reduces idle time between shots and eliminates labor-intensive manual operations. As a result, the overall efficiency of each cycle improves, enabling higher throughput and reduced labor dependency.

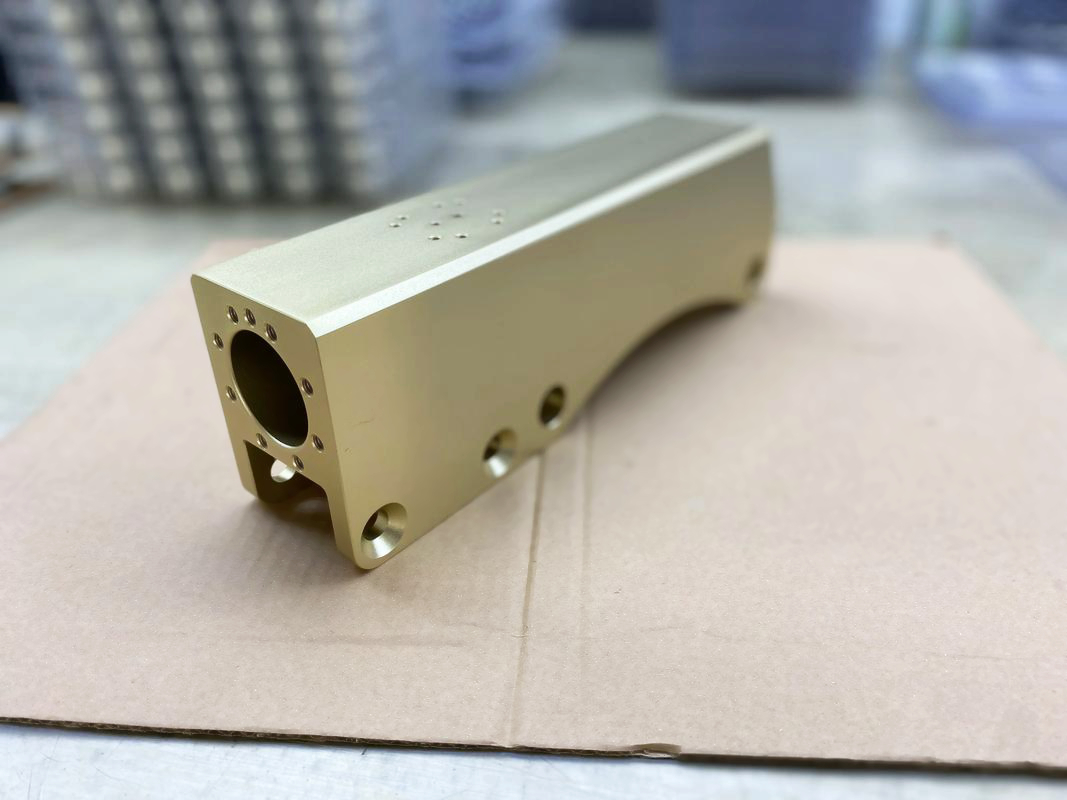

Minimize Secondary Processes with Near-Net-Shape Casting

Secondary operations such as post-machining, polishing, or drilling often inflate unit costs. One of the most effective ways to reduce these costs is by designing components to be as close to net shape as possible directly from the die. This requires precision in mold engineering and strict control over injection parameters to minimize tolerances and reduce the need for finishing.

By implementing simulation tools such as mold flow analysis during the design phase, engineers can predict material flow and air entrapment zones, which helps minimize defects and dimensional inconsistencies. This reduces rework rates and cuts down on time-intensive adjustments after casting.

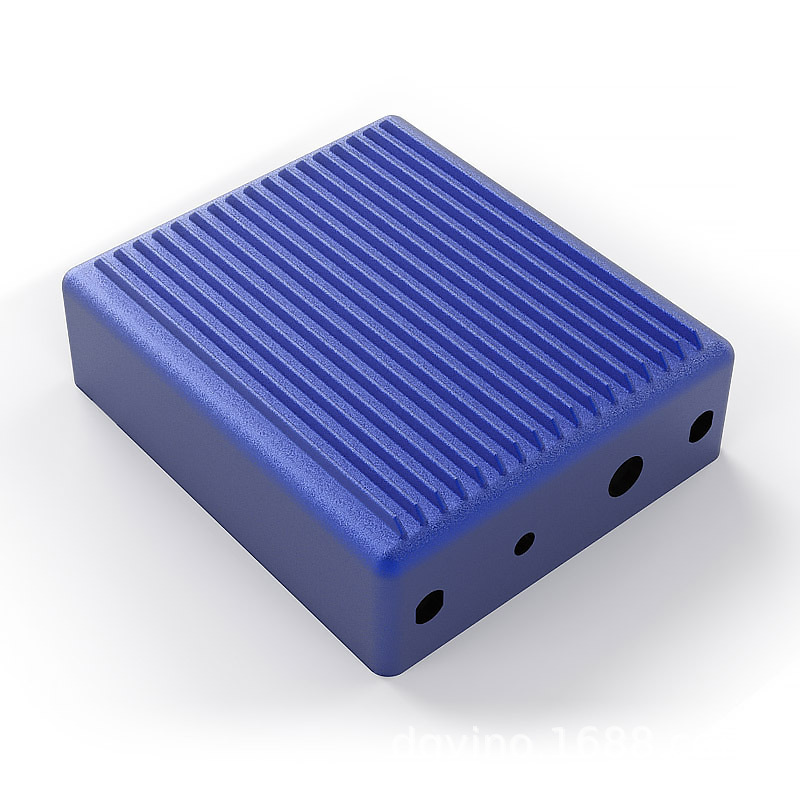

For critical applications like medical device housings or electronic enclosures, tolerances can often be achieved through well-controlled die design alone, eliminating the need for multiple finishing steps.

Adopt Cost-Saving Surface Treatments Strategically

Surface treatments such as anodizing, powder coating, or plating enhance corrosion resistance and part aesthetics but can add significantly to overall cost. Instead of defaulting to high-cost coatings, consider process-matched treatments. For example, chromate conversion coating offers adequate corrosion protection at a lower cost than anodizing for many industrial applications.

For decorative parts in the consumer electronics sector, the use of PVD coatings on die-cast zinc or aluminum can deliver a high-gloss, wear-resistant finish without costly polishing steps. Strategic planning around surface treatment selection can reduce per-part finishing costs by over 30%.

Improve Material Yield and Scrap Management

Reducing the scrap ratio is one of the fastest ways to lower unit cost. Every rejected part not only wastes materials but also consumes machine time, labor, and energy. Tightening process control and leveraging advanced defect detection technologies such as X-ray and CMM measurements enables real-time correction of process deviations, reducing the rate of non-conforming parts.

In addition, effective gating and runner design in the die can minimize flash and overflows, which often lead to material waste. Recycling aluminum scrap within the foundry can reclaim some material value, but keeping the first-pass yield high is a more profitable approach. Alloys such as AlSi12 are known for their excellent casting characteristics and low shrinkage, which aids in reducing casting defects.

Use Modular Tooling for Multi-Part Flexibility

For low- to mid-volume production, traditional tooling amortization can make unit costs uncompetitive. One solution is modular tooling, where interchangeable inserts are used in a shared die base. This allows different part geometries to be cast using a single mold frame, minimizing initial tooling investment and facilitating product iterations without full retooling.

Low-volume manufacturing solutions based on modular die casting systems are especially useful for industries like automotive aftermarket parts or startup electronics hardware, where flexibility is key. This tooling strategy can reduce mold-related costs by up to 40% while preserving tight tolerances and cycle times.

Partner with Integrated Manufacturing Providers

Outsourcing to a die casting supplier that offers end-to-end services—including toolmaking, casting, finishing, and assembly—reduces logistical complexity and overhead. By consolidating the supply chain under one vendor, buyers benefit from bundled pricing, faster turnaround, and reduced transportation and handling costs.

This is especially beneficial for projects like custom GPU frames for electronics or integrated hinge assemblies for consumer devices. Strategic partnerships also allow joint cost-reduction initiatives through design optimization, bulk purchasing of materials, and process automation.

Increase Labor Efficiency Through Automation and Standardization

Labor costs often represent a significant share of total production costs in die casting operations. By standardizing part designs and integrating automation where applicable, manufacturers can dramatically improve operational efficiency. Introducing automated tumbling and sand blasting systems streamlines finishing while reducing human error and manual handling.

In particular, robotic trimming and CNC machining integration help maintain dimensional accuracy and eliminate operator variability. These systems also reduce bottlenecks during high-volume runs, allowing skilled labor to focus on higher-value tasks like quality assurance or die maintenance.

Additionally, training a multi-skilled workforce and implementing lean manufacturing practices, such as 5S and Kaizen, can increase line adaptability and reduce idle time, leading to measurable cost savings across both short- and long-term production cycles.

Control Energy Consumption Through Thermal Management and Efficient Melting

Energy is one of the most underestimated variables in the die casting cost structure. Maintaining optimal furnace conditions and minimizing heat losses in the casting process play a critical role in controlling unit costs. Using high-efficiency melting furnaces and insulating crucibles can significantly reduce energy per kilogram of aluminum cast.

Advanced thermal simulation tools enable precise temperature control in dies and reduce cycle variation due to thermal fatigue. This consistency results in better surface finish and fewer part rejections.

Reusing die heat for preheating ingots or integrating regenerative burners further contributes to energy conservation. Such practices have demonstrated energy cost reductions of up to 15% in large-scale aluminum casting operations.

Optimize Logistics and Inventory with Lean Supply Chain Tactics

Even the most efficient casting processes can lose cost advantages due to inefficient logistics and bloated inventory. Collaborating with suppliers that provide streamlined logistics and JIT delivery can minimize warehousing and obsolescence costs.

Utilizing digital supply chain monitoring and demand forecasting tools helps align procurement schedules with actual production needs. Manufacturers should also aim to reduce part variety and consolidate material SKUs wherever functionally possible. A reduced bill of materials simplifies sourcing and reduces minimum order requirements, improving negotiation leverage and lowering per-unit pricing.

For instance, by unifying component designs across different product lines, a company can source a common A319 aluminum alloy in higher volumes, achieving both scale-based material discounts and better casting yields.

Case Study Summary: Integrated Cost Reduction at Scale

A real-world example of effective cost reduction comes from the Volkswagen ADC12 die casting project. The project focused on reducing cost per unit through a combination of optimized gating design, high-precision tooling with H13X steel, and minimal post-machining via near-net-shape design.

Additionally, switching from a dual-coating system to a single clear coating approach reduced finishing time by 22%. Leveraging in-house machining capabilities and vertical integration further cut transportation and subcontracting costs.

As a result, the customer achieved a 14% reduction in total project costs over a 9-month production cycle, while maintaining automotive-grade dimensional and mechanical requirements.

Conclusion: Strategic Engineering Drives Cost Efficiency

Reducing unit costs in aluminum die casting is not about compromising quality—it is about making informed engineering and supply chain decisions that collectively optimize the entire process. From material selection and tooling design to automation and energy management, each link in the chain offers room for measurable savings.

Success depends on collaboration between design, production, and procurement teams, supported by advanced simulation tools, standardized practices, and long-term supplier partnerships. In a competitive manufacturing landscape, this approach not only lowers cost but also enhances product consistency, delivery speed, and customer satisfaction.

For companies looking to stay ahead in the precision casting market, investing in one-stop die casting services that prioritize cost transparency and manufacturing excellence is the most effective way forward.