H13X

Introduction to H13X

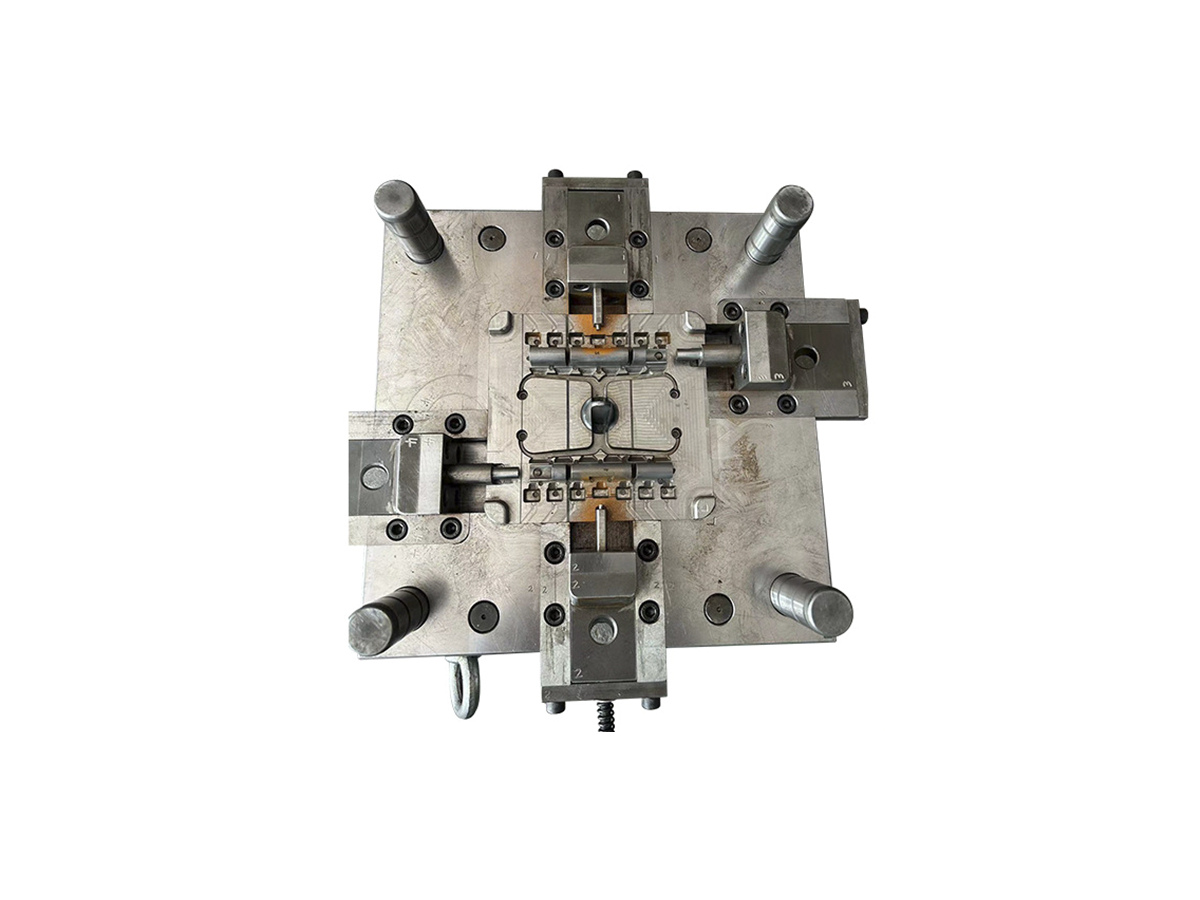

H13X is a modified version of traditional H13 hot work tool steel, engineered for superior thermal fatigue resistance, reduced crack propagation, and extended die life in high-pressure die casting (HPDC) and forging applications. With enhanced cleanliness and microstructural stability, H13X is optimized for precision mold components exposed to cyclic thermal shock and mechanical loading.

At Neway Die Casting, H13X is a preferred tooling material for complex aluminum and zinc die casting molds, ensuring prolonged service cycles and minimal dimensional distortion.

H13X Chemical Composition (Typical Specification)

Element | Weight % | Function |

|---|---|---|

Chromium (Cr) | 4.8–5.5 | Improves hardenability, corrosion, and wear resistance |

Molybdenum (Mo) | 1.2–1.5 | Enhances strength at elevated temperatures |

Vanadium (V) | 0.9–1.2 | Refines grain, improves wear and temper resistance |

Carbon (C) | 0.34–0.39 | Increases hardness and strength |

Silicon (Si) | 0.8–1.2 | Increases tempering resistance |

Manganese (Mn) | 0.25–0.5 | Enhances toughness and hardenability |

Iron (Fe) | Balance | Matrix material |

Compared to conventional H13, H13X offers tighter composition control and reduced non-metallic inclusions for better polishability and heat check resistance.

Physical Properties of H13X

Property | Value & Unit |

|---|---|

Density | ~7.8 g/cm³ |

Thermal Conductivity | 24–27 W/m·K |

Specific Heat Capacity | ~460 J/kg·K |

Coefficient of Thermal Expansion | 11.5–12.5 µm/m·°C |

Melting Point | ~1425 °C |

Stable thermal expansion makes H13X suitable for dimensional control in core inserts and slide units.

Mechanical Properties (Heat Treated to 44–50 HRC)

Property | Typical Value & Unit |

|---|---|

Tensile Strength | 1400–1600 MPa |

Yield Strength | ~1200 MPa |

Elongation | 8–12 % |

Impact Toughness (Charpy V-notch) | >30 J |

Hardness | 44–50 HRC |

Modulus of Elasticity | ~210 GPa |

Mechanical performance aligns with NADCA #207 and DIN 17350 standards for hot work tool steels in die casting.

Die Casting Performance Advantages

H13X is purpose-built for high-cycle, high-thermal-load mold components, offering:

Excellent thermal fatigue resistance—minimizes heat checking in core pins and cavities

High hot strength—maintains geometry under aluminum shot pressures exceeding 1000 bar

Improved toughness—resists chipping or cracking in complex geometries

Excellent nitriding compatibility—enhances surface wear life without distortion

Neway's tool and die manufacturing uses H13X for:

Core inserts, shot sleeves, cavity blocks

High-stress gate and runner areas

Long-life low-volume tooling platforms

Common Applications

H13X is ideal for tooling under aggressive thermal and mechanical conditions, such as:

Aluminum and magnesium die casting core pins

High-cavity permanent molds for automotive and electronics

Slide cores and shut-off components in mass production dies

Tooling for thin-wall castings or parts with rapid filling cycles

Hot forging dies and extrusion tooling

Machining Challenges and Solutions

H13X, like standard H13, hardens rapidly during machining and requires advanced strategies:

Pre-hardened blocks may be rough machined before final heat treatment

PVD-coated carbide tools recommended for extended tool life

Proper fixturing and controlled feeds reduce chatter in high-speed finishing

EDM and polishing post-treatments achieve precision within ±0.01 mm

Neway applies 5-axis CNC, gun drilling, and heat-treatment-integrated workflows for dimensional accuracy and mold integrity.

Surface Treatment Compatibility

H13X supports advanced surface hardening techniques to extend tooling life:

Nitriding for wear resistance and thermal barrier layers

PVD coatings like CrN or TiAlN for reduced soldering and friction

Cryogenic treatment (optional) for structure refinement

These treatments are especially beneficial in molds with frequent thermal cycling and metal flow turbulence.

FAQs

How does H13X differ from standard H13 in thermal fatigue resistance?

Can H13X be nitrided without compromising core hardness?

What is the best heat treatment cycle for H13X mold blocks?

Is H13X suitable for ultra-high-pressure aluminum casting dies?

How long is the average die life when using H13X vs P20?