Tungsten Carbide

Introduction to Tungsten Carbide

Tungsten carbide is a sintered composite material composed of tungsten carbide particles and a metallic binder, typically cobalt. Renowned for its extreme hardness, thermal resistance, and compressive strength, it is widely used in precision dies and wear-resistant inserts for high-pressure die casting and metal forming operations.

At Neway Die Casting, tungsten carbide is used in specialized tooling applications that demand exceptional durability under abrasive wear, high loads, and elevated temperatures.

Tungsten Carbide Chemical Composition (Typical WC-Co Grade)

Component | Weight % | Function |

|---|---|---|

Tungsten Carbide (WC) | 85–95 | Primary phase, provides hardness and wear resistance |

Cobalt (Co) | 5–15 | Binder phase, offers toughness and impact strength |

Trace elements (TiC, TaC, NbC) | ≤ 1 | Grain refinement, oxidation resistance |

Grades with lower cobalt offer higher hardness, while higher cobalt improves impact resistance.

Physical Properties of Tungsten Carbide

Property | Value & Unit |

|---|---|

Density | 14.5–15.1 g/cm³ |

Melting Point (WC) | ~2870 °C |

Thermal Conductivity | 84–100 W/m·K |

Coefficient of Thermal Expansion | 4.5–6.5 µm/m·°C |

Electrical Conductivity | 2.5–5 % IACS |

Hardness | 1400–1900 HV30 |

Tungsten carbide’s thermal and structural stability under load is unmatched among tool materials.

Mechanical Properties (Typical WC-12Co)

Property | Value & Unit |

|---|---|

Compressive Strength | >6000 MPa |

Modulus of Elasticity | 530–700 GPa |

Transverse Rupture Strength | 2200–3000 MPa |

Fracture Toughness (K_IC) | 8–15 MPa·m¹/² |

Hardness | ~90 HRA |

These properties ensure die life longevity in high-volume, high-pressure casting environments.

Die Casting Tooling Characteristics

Tungsten carbide is favored in die casting tooling for extreme conditions:

Outstanding resistance to thermal cracking and erosion

Superior dimensional stability under repeated thermal cycling

Low coefficient of friction reduces galling and soldering

Exceptional compressive strength to withstand shot pressures exceeding 1500 bar

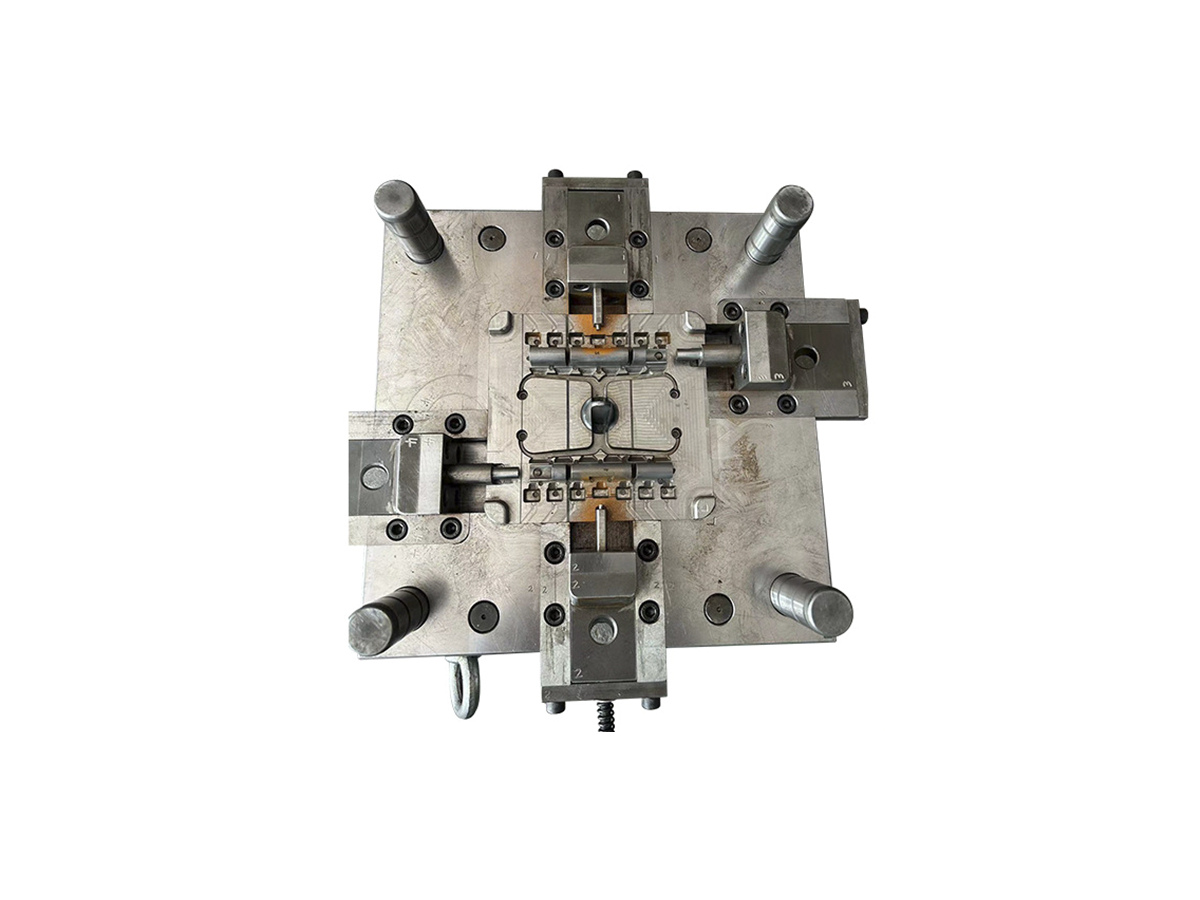

At Neway, tungsten carbide is implemented in critical die sections such as:

Core pins and ejector pins

Gate inserts and plunger tips

Die bushings and thermal-resistant mold cavities

Common Applications

Tungsten carbide is applied where tool life and surface durability are critical:

Aluminum and copper alloy die casting inserts

Automotive transmission mold cavities

Precision ejector pins in mass production tools

Valve seats and wear pads for fluid control

High-pressure nozzle and gate sections

Machining Challenges and Solutions

Due to its extreme hardness and brittleness, tungsten carbide presents significant machining challenges:

Cannot be conventionally milled or drilled—requires grinding or EDM

Brittle failure may occur under improper fixturing

Heat buildup during finishing must be minimized

Neway’s advanced machining process includes:

High-precision wire EDM for complex geometries

Diamond wheel grinding for ±0.002 mm tolerance finish surfaces

Laser structuring and polishing for critical sealing applications

Surface Treatment Compatibility

While naturally hard and corrosion-resistant, tungsten carbide can also benefit from:

PVD coatings to reduce friction in sliding interfaces

Polishing or lapping for mirror-grade surfaces

Ion implantation or nitriding for fatigue resistance in mold inserts

FAQs

What are the differences between tungsten carbide and tool steels like H13 or D2?

Can tungsten carbide be used for full die sets or just inserts?

How do you machine complex features in tungsten carbide components?

What is the typical die life of WC-based inserts under aluminum casting?

Is cobalt binder content customizable for toughness vs hardness trade-offs?