Precision-Manufactured Aluminum Die Cast Housings for Consumer Electronics

The consumer electronics market demands a balance of functionality, durability, and aesthetic appeal. As devices become more compact and advanced, the need for precise, lightweight, and heat-dissipating enclosures has grown significantly. Aluminum die casting has emerged as a leading solution for manufacturing high-quality housings that meet both engineering and design requirements.

At Neway, we provide aluminum die casting services that enable OEMs to develop sleek, structurally sound, and scalable housings for devices such as smartphones, smartwatches, wearables, Bluetooth speakers, and more.

Why Aluminum Die Casting is Ideal for Electronics Housings

High-pressure aluminum die casting offers precise control over dimensions, surface finish, and material properties. It allows thin-walled components with complex geometries to be produced at scale, delivering both performance and design integrity.

Key Advantages

Density of 2.7 g/cm³ provides strong, lightweight enclosures

Dimensional tolerances up to ±0.02 mm for critical mounting and interface points

Thermal conductivity as high as 235 W/m·K for heat management

Cycle times of 30–60 seconds per part in high-volume production

Surface quality suitable for direct coating, painting, or branding

These characteristics are critical for achieving the slim profiles and integrated features expected in today’s electronics.

Common Applications in Consumer Devices

Aluminum die cast housings are widely used in external shells and internal frames requiring structural support, heat dissipation, or visual appeal.

Product Category | Housing Components | Key Requirements |

|---|---|---|

Smartphones & tablets | Mid-frames, battery covers | Tight tolerances, EMI shielding, premium finishes |

Smartwatches | Enclosures, bezels, strap interfaces | Wear resistance, corrosion protection, compact geometry |

Wireless speakers | Shells, subframes, battery compartments | Acoustic performance, ruggedness, heat dispersion |

Media devices | Set-top box casings, streaming device frames | Heat dissipation, connector alignment, ease of assembly |

Wearable electronics | Sensor housings, smart bands | Lightweight design, tight dimensional accuracy |

Materials: Aluminum Alloys for Electronics Housings

Neway casts with industry-proven alloys that offer the ideal combination of strength, thermal performance, and surface aesthetics. Common choices include:

Alloy | Density (g/cm³) | Tensile Strength (MPa) | Characteristics | Applications |

|---|---|---|---|---|

A380 | 2.74 | 317 | Excellent dimensional stability, corrosion resistance | Phone bodies, laptop frames |

AlSi12 | 2.66 | 250–280 | High castability, great for thin-wall sections | Speaker housings, wearables |

ADC12 | 2.75 | 250–290 | Good mechanical strength, easy finishing | Set-top boxes, control unit enclosures |

These alloys comply with ASTM B85 and JIS H5302 standards, ensuring quality and repeatability across consumer product lines.

Precision and Surface Quality

Electronic housings must meet strict dimensional and visual specifications to ensure part fit and seamless product aesthetics. At Neway, we maintain:

Tolerances of ±0.05 mm for general dimensions and ±0.02 mm for mating features

Wall thickness as low as 1.2 mm with uniform consistency

Porosity levels below 0.5% verified using X-ray and vacuum tests

Surface roughness Ra ≤ 1.6 µm using tumbling and sand blasting

Flatness within 0.1 mm across sealing and display surfaces up to 250 mm

This level of control ensures zero interference in assemblies and optimal performance for buttons, ports, screens, and thermal interfaces.

Post-Processing and Surface Treatments

Surface finish is not only cosmetic—it also enhances corrosion resistance, grip, and thermal control. Neway’s in-house post-processing includes:

CNC machining: ±0.01 mm for slots, threads, and alignment features

Anodizing: MIL-A-8625 Type II and III for scratch resistance and color uniformity

Powder coating: 50–100 µm layer thickness, ISO 2409 adhesion-compliant

Painting: Available in gloss, matte, and textured finishes

Assembly: Gaskets, fasteners, EMI liners, and sub-assembly integration

These treatments enhance product appeal while meeting ISO 9227 salt spray and ISO 2812 solvent resistance benchmarks.

Tooling and Production Capabilities

Neway’s tool and die making supports the creation of high-output tooling with complex aesthetic and functional features.

Cavity tolerance: ±0.02 mm

Die life: 75,000–150,000 cycles using H13 tool steel

Lead time: 4–6 weeks for hardened production tooling

Multi-cavity designs for high-volume programs

Rapid prototyping available for early-stage product testing

All tooling is validated through mold flow simulation, and first articles include full dimensional and cosmetic inspection reports.

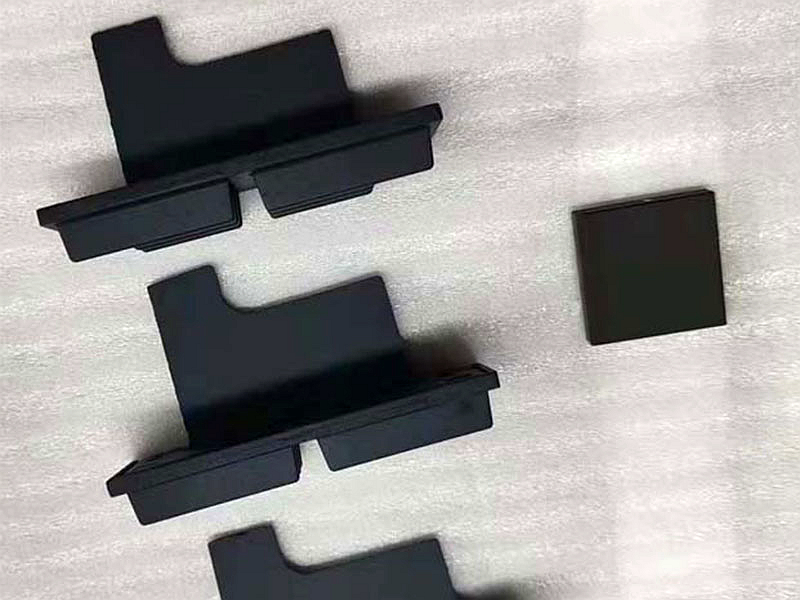

Case Study: Aluminum Enclosure for Smart Audio Device

A client required a 3-piece housing system for a portable smart speaker with voice activation and thermal sensors. Design targets included:

Total housing weight < 900 g

Operating temperature: up to 70°C

Flatness < 0.08 mm on the mounting plane

Surface finish: powder-coated in metallic gray with brand deboss

Neway cast the part using A380 aluminum in a four-cavity die. After machining, powder coating, and laser branding, the product passed drop tests (IEC 60068-2-31) and salt spray testing. Dimensional Cpk exceeded 1.33 and cosmetic quality was rated “A” per the client’s standards.

Why Top Brands Choose Neway

Neway’s full-service die casting workflow ensures fast, repeatable production of high-precision aluminum housings:

Design consultation for manufacturability and assembly

Rapid tool development and validation

End-to-end process control: die casting, machining, finishing, packaging

Low-volume and mass production under ISO 9001:2015

Stringent inspection including CMM, X-ray, and cosmetic QA

Whether you're designing the next generation of smart home devices or wearable health tech, Neway ensures every detail is executed with precision.

Conclusion

Aluminum die casting delivers lightweight, thermally efficient, and visually appealing housings that meet the evolving demands of consumer electronics. Its ability to scale from concept to global production makes it the backbone of modern enclosure manufacturing. At Neway, we combine tooling expertise, material control, and finishing capabilities to deliver ready-to-integrate housings that enhance both function and brand image.

To discuss your project or request a quote, contact Neway today.

FAQs

What is the standard wall thickness for aluminum die cast electronics housings?

Which aluminum alloys are best for smartphone or smartwatch enclosures?

How are cosmetic and dimensional defects controlled in die cast housings?

What finishing options are available for premium consumer electronics?

Can aluminum die cast housings integrate with heat sinks or EMI shielding?