H13 Steel

Introduction to H13 Steel

H13 is a chromium-based hot work tool steel, known for its excellent toughness, high thermal stability, and good wear resistance at elevated temperatures. Commonly used for die casting molds and high-stress tooling, H13 is renowned for maintaining its mechanical properties under extreme heat and pressure. It is a preferred material for molds in aluminum, zinc, and magnesium die casting applications.

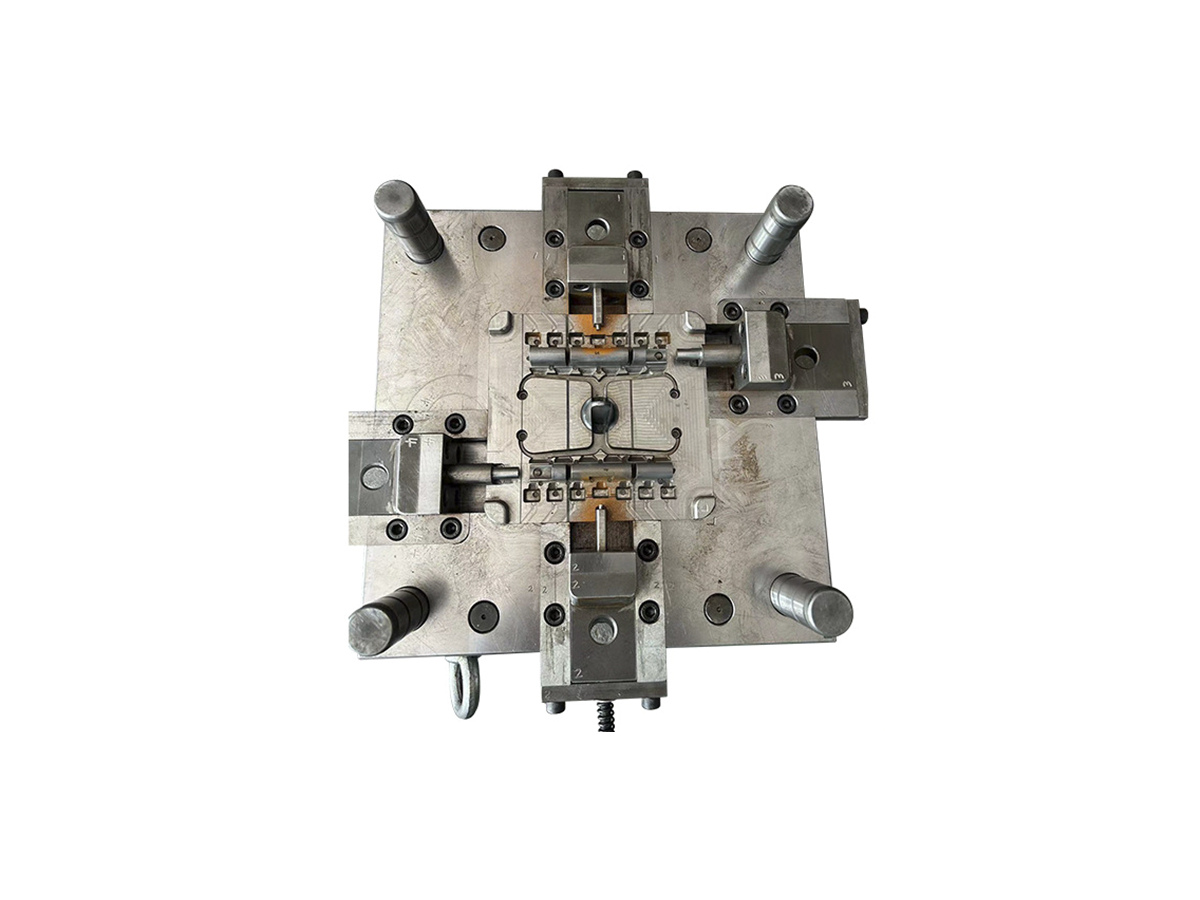

At Neway Die Casting, H13 steel is widely used for mold base components and core inserts, offering superior thermal fatigue resistance, excellent dimensional stability, and high strength in high-pressure die casting and plastic injection molding tools.

H13 Steel Chemical Composition (Typical per ASTM A681)

Element | Weight % | Function |

|---|---|---|

Chromium (Cr) | 4.75–5.5 | Provides wear resistance, corrosion resistance |

Molybdenum (Mo) | 1.3–1.8 | Improves strength at elevated temperatures |

Vanadium (V) | 0.3–0.5 | Refines grain structure and increases hardness |

Carbon (C) | 0.32–0.45 | Provides hardness and strength |

Manganese (Mn) | 0.2–0.6 | Enhances toughness and hardenability |

Silicon (Si) | 0.8–1.2 | Improves resistance to thermal expansion and oxidation |

Iron (Fe) | Balance | Matrix material |

The high chromium and molybdenum content enhances its resistance to thermal cycling, while vanadium ensures its hardness and toughness remain intact during die operation.

Physical Properties of H13 Tool Steel

Property | Value & Unit |

|---|---|

Density | 7.8 g/cm³ |

Thermal Conductivity | 24–30 W/m·K |

Specific Heat Capacity | ~460 J/kg·K |

Coefficient of Thermal Expansion | 11.5–12.5 µm/m·°C |

Electrical Resistivity | ~0.6 µΩ·m |

Delivery Hardness | ~300–350 HB (Pre-hardened to 28–34 HRC) |

H13's thermal conductivity makes it an excellent choice for tooling in die casting molds, where uniform temperature control is critical.

Mechanical Properties (Heat Treated to 50–54 HRC)

Property | Typical Value & Unit |

|---|---|

Tensile Strength | 1300–1600 MPa |

Yield Strength | ~1200 MPa |

Hardness | 50–54 HRC |

Impact Toughness (Charpy) | 25–35 J |

Elongation | 10–15 % |

Modulus of Elasticity | ~210 GPa |

These properties enable H13 to maintain structural integrity and resist cracking and distortion, even under extreme die casting pressures and temperatures.

Die Casting Mold Performance Characteristics

H13 is particularly well-suited for tooling applications where both thermal resistance and strength are required:

Thermal stability: Withstands high-temperature gradients in aluminum and zinc die casting molds without cracking or warping

Wear resistance: Resists galling and erosion in high-velocity, abrasive environments

Toughness: Maintains ductility and impact resistance even at elevated temperatures

Dimensional stability: Excellent retention of shape and size during thermal cycling and mechanical stress

At Neway Die Casting, we use H13 in critical tooling applications such as:

Core inserts for aluminum and zinc die casting molds

Gate inserts in multi-cavity molds for fast cycle time

Die inserts and sliders subjected to high pressure and thermal cycling

Punches and ejector pins in both die casting and injection molding applications

Common Applications

H13 is ideal for a wide range of high-temperature tooling applications:

Die casting molds: Core pins, cavity inserts, gate inserts, and sliders

Plastic injection molds: Mold frames and structural components

Forging dies: For hot-forming operations in the automotive and aerospace industries

Hot stamping dies: For the production of high-strength steel automotive components

Extrusion dies: For aluminum, copper, and steel extrusion processes

Machining Challenges and Solutions

H13 steel, while well-suited for high-temperature environments, presents some challenges during machining:

Hardness: Hardens quickly during heat treatment, requiring specialized grinding or EDM for fine features

Tool wear: Due to its high hardness and strength, it can cause rapid wear on carbide tooling during machining

Heat management: Machining requires appropriate cooling strategies to avoid heat-induced distortion

Neway's CNC machining team ensures optimal results using:

High-speed carbide tooling and specialized coatings (e.g., TiAlN, TiCN) to reduce tool wear

Wire EDM for fine geometries and intricate designs

Controlled coolant delivery systems for effective chip removal and temperature management

Surface Treatment Compatibility

H13’s alloy properties support a range of surface treatments to enhance wear resistance and performance:

Nitriding: Increases surface hardness and wear resistance while maintaining core toughness

PVD coatings: TiN and CrN coatings to enhance resistance to wear and oxidation

Cryogenic treatment: Further improves toughness and reduces residual stress, increasing die life in high-cycle applications

These treatments ensure longer mold life, reduced maintenance costs, and improved performance in critical tooling operations.

FAQs

How does H13 compare to P20 in terms of thermal fatigue resistance?

Can H13 be used in both die casting and injection molding tools?

What is the typical mold life expectancy when using H13 in high-volume die casting?

What is the ideal heat treatment cycle for H13 tool steel?

Is H13 suitable for deep cavity die casting molds or large structural components?