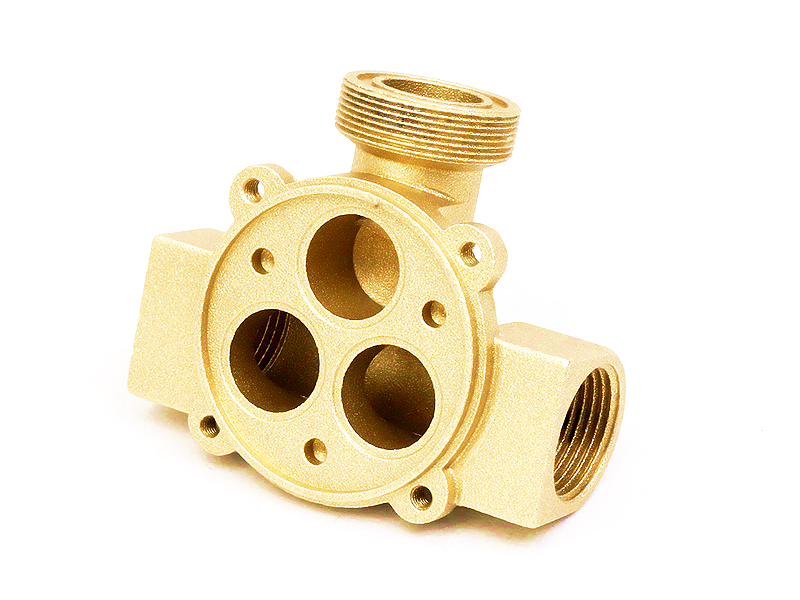

Durable Brass Die Cast Components for Pump Cases and Accessories

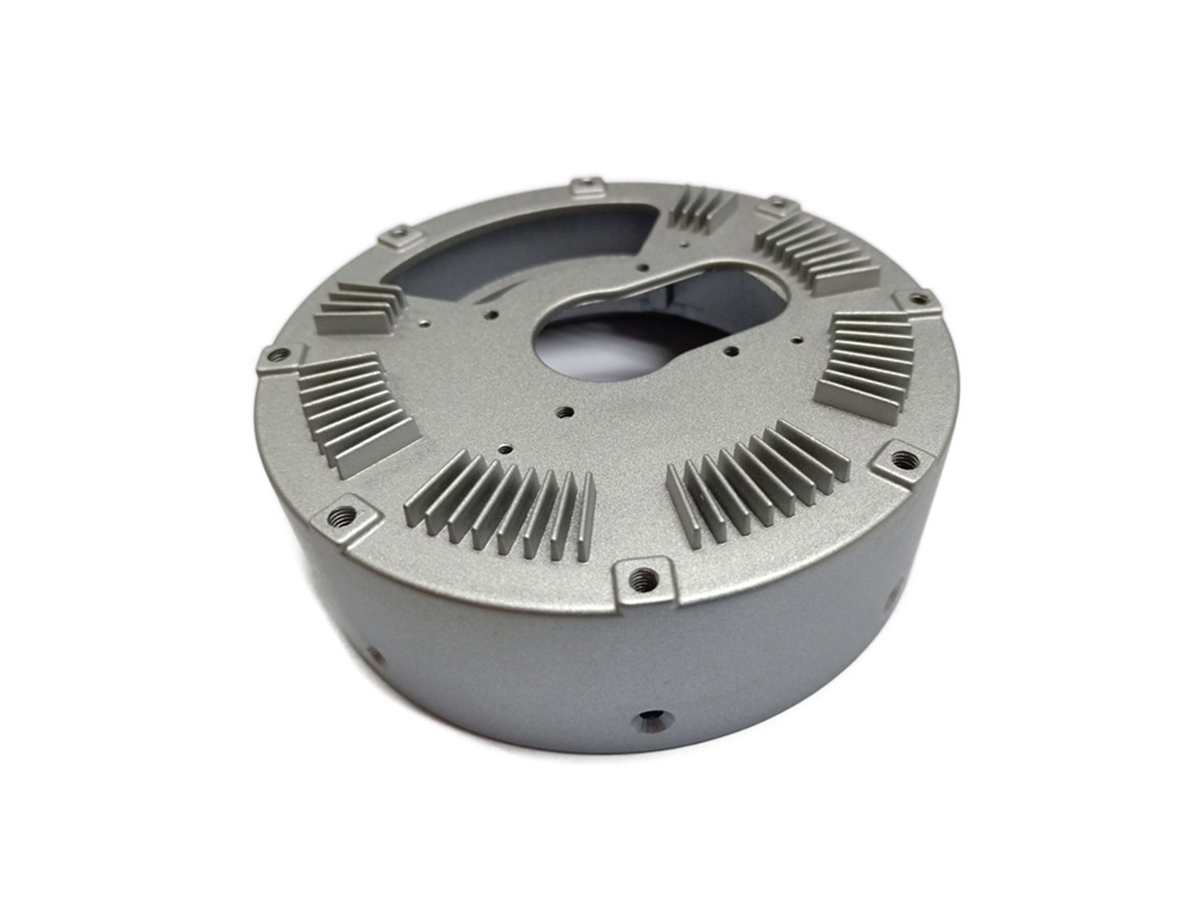

Pump systems require dimensionally stable, corrosion-resistant, and mechanically robust components. Whether in domestic water systems, industrial chemical transfer, or HVAC circulation, pump cases and accessories must endure fluctuating pressure, flow rates, and environmental conditions without degradation. Brass die casting offers an ideal solution for producing high-precision, corrosion-resistant components with complex geometries and high mechanical strength.

At Neway, we specialize in brass die casting for pump housings, impeller enclosures, fittings, and support hardware. Using high-performance copper-zinc alloys, our process ensures reliable, leak-resistant parts with excellent dimensional accuracy and long service life in fluid-handling applications.

Why Brass Die Casting is Ideal for Pump Components

Brass is a proven material for pump systems thanks to its excellent corrosion resistance, thermal conductivity, machinability, and strength. High-pressure brass die casting enhances manufacturing efficiency by producing detailed shapes with integrated features in a single operation, minimizing post-machining and assembly time.

Key Advantages

Tensile strength: 350–550 MPa

Corrosion resistance: suitable for potable water, light chemicals, and seawater environments

Pressure tolerance: up to 2.5 MPa (PN25) for housing components

Dimensional tolerance: ±0.02 mm on sealing and mating surfaces

High thermal conductivity: ~100–120 W/m·K for heat dissipation in motor housings

Brass also offers low friction and natural resistance to scaling and fouling, making it an excellent choice for long-term hydraulic and mechanical integrity.

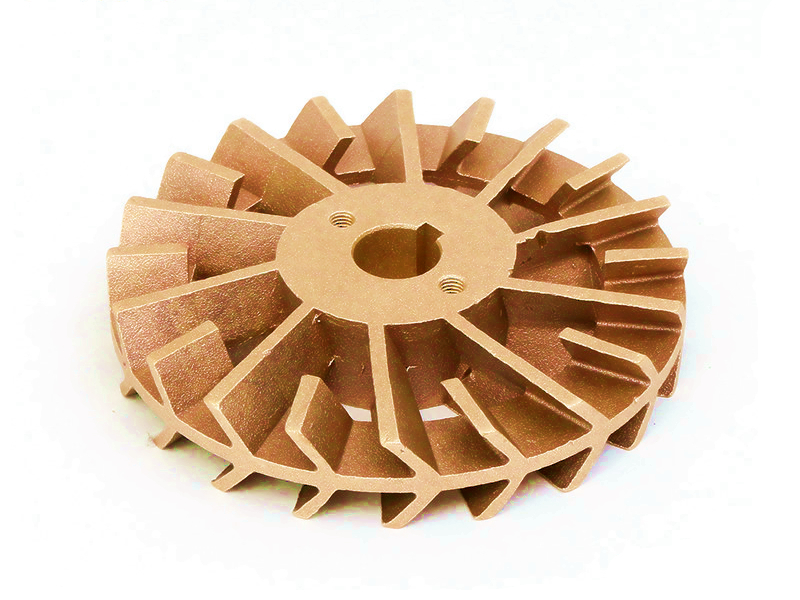

Common Pump Components Produced by Brass Die Casting

Die casting supports the production of intricate pump parts with tight tolerances and integrated functional features, enabling compact designs and fewer failure points.

Component Type | Application Examples | Key Functional Requirements |

|---|---|---|

Pump Housings | Centrifugal pump casings, impeller enclosures | Pressure resistance, sealing accuracy, internal channeling |

Connector Ports | Threaded inlets/outlets, quick couplings | Leak-proof sealing, standard thread conformity |

Bearing Brackets | Mounting bases, shaft supports | Dimensional stability, vibration tolerance |

Volute Chambers | Internal fluid guidance structures | Smooth fluid flow, corrosion resistance |

Accessory Components | Sensor bosses, valve seats, check valve inserts | Tight fit, corrosion resistance, post-machining capability |

Brass Alloys Used in Pump Die Casting

Neway works with a wide range of brass alloys tailored for pressure-bearing and corrosion-sensitive environments. All alloys meet ASTM B584, EN 1982, and ISO 4261 standards.

Alloy | Copper (%) | Zinc (%) | Tensile Strength (MPa) | Best Use Cases |

|---|---|---|---|---|

~58 | ~38 | ~400 | Pump housings, volutes, structural enclosures | |

~62 | ~36 | ~480 | Marine and saltwater systems, chemical resistance | |

~61 | ~35 | ~345 | Threaded ports, CNC-machined inserts and adapters | |

~63 | ~37 | ~450 | Thin-walled fluid control components, sensor bosses |

Lead-free and low-lead brass options are available to comply with potable water standards like NSF/ANSI 61 and the U.S. Safe Drinking Water Act.

Dimensional Accuracy and Functional Geometry

Precision is essential in pump systems to maintain pressure control, flow consistency, and mechanical alignment. Our process ensures repeatability across high-volume production.

Wall thickness: 1.5–5.0 mm for enclosures and ports

Tolerances: ±0.02 mm for thread features and sealing flanges

Flatness: ≤ 0.03 mm on mounting surfaces

Concentricity: ≤ 0.05 mm between shaft and bearing seats

Surface finish: Ra ≤ 1.6 µm achievable with tumbling or post-machining

Features like O-ring grooves, flanges, screw bosses, and pressure test ports can be cast directly, minimizing secondary operations.

Surface Finishing and Corrosion Protection

To enhance durability and performance, especially in chemically or thermally aggressive environments, Neway offers full post-processing capabilities:

Electroplating: tin, nickel, or chrome plating for chemical resistance or aesthetics

Powder coating: epoxy or polyester finishes up to 100 µm for exterior housings

Painting: color coding or primer layers for equipment identification

Assembly: integration of threaded inserts, seals, valve elements, or gaskets

All coatings comply with RoHS, REACH, and relevant industrial plumbing and HVAC standards for safety and durability.

Tooling and Production Capabilities

Neway provides full tool and die making in-house, allowing rapid development and tight control over part geometry and finish quality.

Die steel: H13 tool steel hardened to handle high-pressure brass casting

Tool life: 150,000–400,000 shots depending on complexity and alloy

Shot cycle time: 25–40 seconds

Lead time: 3–6 weeks with full DFM and mold flow simulation

Rapid prototyping for design validation and early-stage fluid testing

We support both low-volume custom jobs and mass production with multi-cavity tools and automated trimming.

Case Study: Brass Pump Housing for Circulating HVAC Unit

A client required a custom pump housing for a compact HVAC water circulation module. Requirements included:

1.6 MPa pressure resistance

Threaded G1 inlet/outlet ports with ±0.02 mm tolerance

Wall thickness: 3 mm with localized thickening at impeller cavity

Nickel-plated exterior for corrosion resistance

Annual volume: 180,000 units

Neway used Brass 380 for its balance of castability and mechanical strength. A 2-cavity mold produced housings with integrated bosses and impeller seat geometry. Post-casting, CNC machining refined thread engagement and sealing faces. The product passed all burst, thermal cycle, and flow rate tests, achieving a 99.4% first-pass yield.

Why Pump OEMs Choose Neway

Neway delivers dependable brass casting services backed by material expertise and advanced production systems:

ISO 9001:2015-certified production and quality management

Integrated machining, plating, and assembly for complete part delivery

Support for UL, CE, NSF, and WRAS certifications

Custom solutions for HVAC, water supply, irrigation, and chemical pumps

Global fulfillment with consistent quality from prototype to scale

Whether your application involves clean water, saline solutions, glycol, or light chemicals, Neway delivers precision-engineered pump components with proven longevity.

Conclusion

Brass die casting enables the efficient and reliable production of high-performance pump housings and accessories for fluid control systems. Combining excellent corrosion resistance, dimensional accuracy, and manufacturing efficiency, brass castings are essential for durable, compact, and leak-free pump solutions. At Neway, we combine tooling, casting, machining, and finishing to deliver complete solutions for pump OEMs and industrial manufacturers worldwide.

Contact Neway for technical consultation and a custom quote to begin your brass die casting project.

FAQs

What brass alloys are best for pump housings exposed to water and chemicals?

How accurate are thread and flange tolerances in die cast brass fittings?

Can brass die castings be used in high-pressure HVAC or circulation pumps?

What post-treatments improve brass corrosion resistance for pump enclosures?

What is the lead time for tooling and production of custom brass pump parts?