How does tool steel hardness affect die life?

How Does Tool Steel Hardness Affect Die Life?

The Role of Hardness in Die Casting Tool Performance

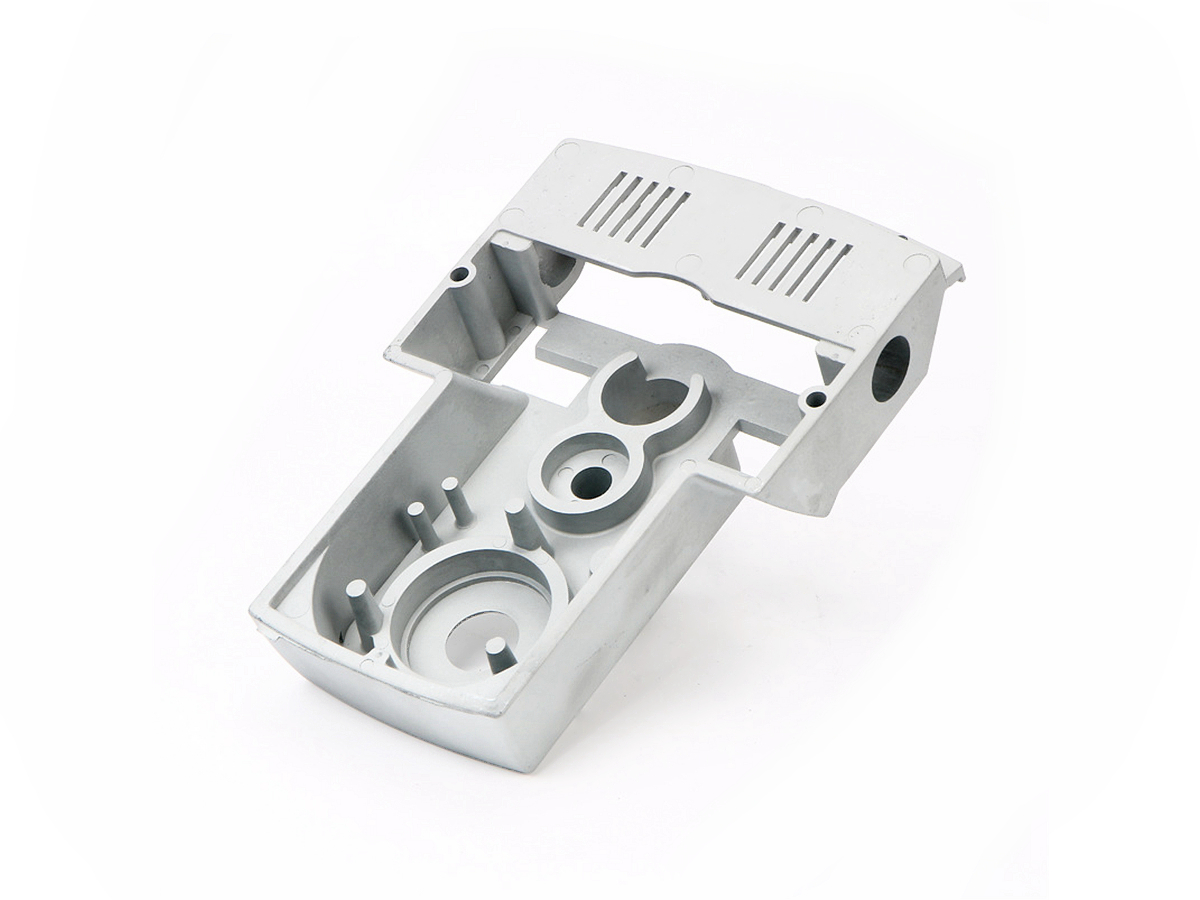

Tool steel hardness plays a pivotal role in determining the life and durability of die casting molds. It directly influences resistance to wear, thermal fatigue, erosion, and deformation. For high-pressure die casting processes—especially involving alloys like aluminum and copper—maintaining optimal hardness is essential to minimize mold damage and maintain dimensional accuracy over long production runs.

At Neway, we tailor tool and die making services based on the hardness profiles of steels such as H13, H13X, and P20 to ensure efficient, long-lasting die tools.

Optimal Hardness Ranges for Tool Steels

Each tool steel has a recommended hardness range depending on its intended use and thermal load environment:

Tool Steel | Typical Hardness (HRC) | Application Scope |

|---|---|---|

H13 | 44–52 HRC | High-pressure die casting, aluminum/copper molds |

H13X (Modified) | 46–53 HRC | Extended die life in large-volume production |

P20 | 28–32 HRC | Prototype and low-pressure molds |

D2 / A2 | 55–62 HRC | Cold-working or trimming dies |

Harder steels generally provide better resistance to abrasive wear and erosion. However, excessive hardness can reduce toughness, making the tool more susceptible to cracking under thermal shock or mechanical stress.

Balancing Hardness with Die Life Requirements

The relationship between hardness and die life is not linear—optimal die performance results from a balance between:

Hardness (wear resistance): Critical for maintaining cavity shape under high-velocity metal flow

Toughness (crack resistance): Required to absorb thermal cycling without fracturing

Thermal conductivity: Often decreases as hardness increases, affecting cooling efficiency

For high-cycle casting of aluminum die castings, H13 tool steel hardened to around 48–50 HRC offers a proven compromise between wear resistance and toughness, delivering tool life exceeding 100,000 shots. For copper alloy casting, higher surface hardness and selective use of tungsten carbide inserts may be necessary to resist erosion.

Recommended Services to Maximize Die Life Through Hardness Optimization

Neway provides a full range of tooling solutions designed for longevity:

Tool Steel Selection and Fabrication

Tool and Die Making: Custom die fabrication using H13, H13X, and P20 steels tailored to application hardness requirements.

Casting Process Integration

Aluminum Die Casting: Supported by hardened steel tools optimized for thermal cycles and pressure.

Copper Die Casting: High-hardness inserts and erosion-resistant die zones.

Engineering and Life Simulation

Die Casting Engineering: Die life prediction, hardness analysis, and material compatibility modeling.

One-Stop Service: Complete integration of die materials, heat treatment, and finishing for reliable long-run production.