When should I choose P20 over H13 for die tools?

When Should I Choose P20 Over H13 for Die Tools?

Core Differences Between P20 and H13 Tool Steels

Choosing between P20 and H13 tool steel for die casting depends on production volume, thermal exposure, and required mold performance. Each steel type offers distinct advantages depending on the casting conditions and tooling budget.

Property | P20 Tool Steel | H13 Tool Steel |

|---|---|---|

Type | Pre-hardened plastic mold steel | Hot-work tool steel |

Hardness (Typical) | ~28–32 HRC | ~44–52 HRC |

Thermal Fatigue | Limited | Excellent |

Max Operating Temp | ~400°C | ~600°C |

Machinability | High | Moderate |

Suitable Processes | Low-pressure or prototyping dies | High-pressure, long-run die casting |

When to Use P20 Tool Steel

P20 tool steel is preferred in scenarios where thermal loads and production demands are moderate:

1. Short-Run or Prototype Die Casting

P20 is ideal for prototype or pilot tooling due to its lower cost, excellent machinability, and reduced lead time. It allows faster mold fabrication, especially for rapid pre-production sampling.

2. Low-Pressure or Gravity Die Casting

P20 can be used in die casting applications with lower thermal shock, such as gravity-fed dies or low-pressure aluminum casting where mold temperatures stay below 400°C.

3. Plastic or Non-Ferrous Tool Inserts

For hybrid tooling setups involving plastic injection or secondary processing of low-temperature alloys, P20 provides sufficient strength and polishability.

When Not to Use P20

Avoid P20 for:

High-pressure die casting of aluminum or copper alloys

Long production runs (over 50,000 shots)

Mold cavities exposed to cyclic high-temperature stress

These applications require H13 or H13X, which resists thermal fatigue and soldering far better.

Recommended Die Tooling Services for Informed Material Selection

For optimal tool performance based on casting conditions, we offer:

Tool Steel Engineering and Fabrication

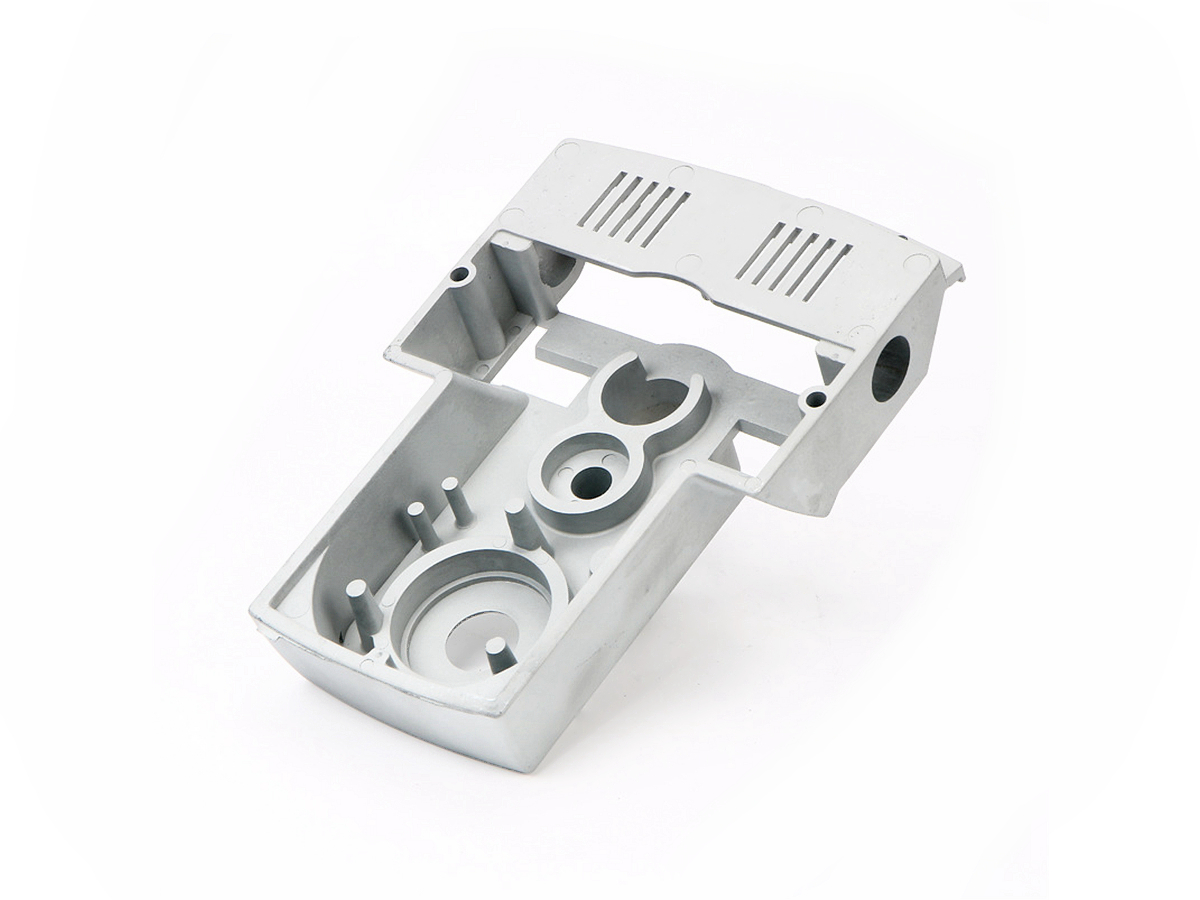

Tool and Die Making: Full-service die fabrication in P20, H13, H13X, and carbide grades.

Process-Matched Casting Services

Aluminum Die Casting: Supports both prototype and high-volume aluminum parts.

Copper Die Casting: High-temperature casting requiring H13-grade tooling.

Design and Prototyping

Die Casting Engineering: Match die material with thermal demands and cycle targets.

Rapid Prototyping: Fast turnaround on P20-based soft tools for early validation.

Use our one-stop service to ensure the correct die steel is selected for your production strategy—balancing cost, tool life, and part quality.