P20 Steel

Introduction to P20 Steel

P20 tool steel is a chromium-molybdenum alloyed steel that is delivered in a pre-hardened condition, offering an optimal balance of hardness, toughness, and machinability. It is specifically designed for applications requiring precise tooling and mold components, including die casting molds, plastic injection molds, and general tooling components. The pre-hardened nature of P20 steel eliminates the need for post-hardening treatment, making it a cost-effective solution for high-volume manufacturing.

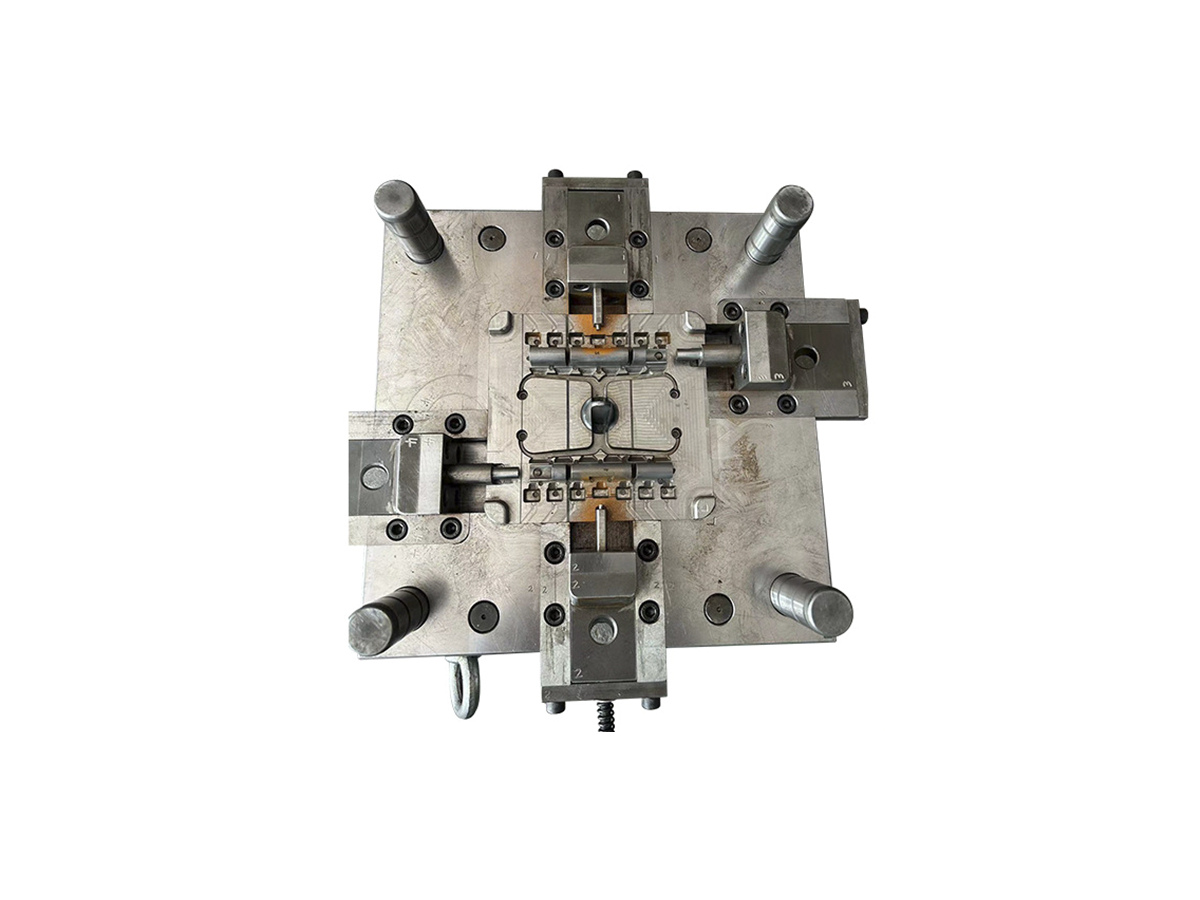

At Neway Die Casting, P20 steel is widely used in tooling applications for die casting and plastic injection molding, where high precision and dimensional stability are essential. Its uniform hardness and good machinability allow for quick turnaround times in mold production without compromising performance.

P20 Steel Chemical Composition (Typical per DIN 1.2311 / ASTM A681)

Element | Weight % | Function |

|---|---|---|

Chromium (Cr) | 1.8–2.1 | Increases hardness, wear resistance, and corrosion resistance |

Molybdenum (Mo) | 0.15–0.25 | Enhances temper resistance and high-temperature strength |

Carbon (C) | 0.28–0.40 | Provides hardness and structural strength |

Manganese (Mn) | 0.6–1.0 | Improves toughness and hardenability |

Silicon (Si) | 0.2–0.8 | Enhances resistance to thermal expansion and increases strength |

Nickel (Ni) | 0.8–1.0 (in P20+Ni grades) | Improves core toughness and polishability |

Iron (Fe) | Balance | Primary matrix material |

The chemical composition of P20 tool steel gives it a combination of high hardness and toughness, making it ideal for use in mold bases, inserts, and other tooling components exposed to high-stress conditions.

Physical Properties of P20 Tool Steel

Property | Value & Unit |

|---|---|

Density | ~7.85 g/cm³ |

Thermal Conductivity | 28–33 W/m·K |

Coefficient of Thermal Expansion | 12.0 µm/m·°C |

Specific Heat Capacity | ~460 J/kg·K |

Electrical Resistivity | ~0.6 µΩ·m |

Delivery Hardness | ~280–320 HB (Pre-hardened to ~30–35 HRC) |

P20 steel's thermal conductivity and coefficient of thermal expansion make it suitable for mold base applications where consistent cooling and dimensional stability are required, especially in high-cavity die casting.

Mechanical Properties (Pre-Hardened Condition)

Property | Typical Value & Unit |

|---|---|

Tensile Strength | 950–1100 MPa |

Yield Strength | ~800 MPa |

Hardness | 30–35 HRC |

Elongation | 12–18 % |

Modulus of Elasticity | ~205 GPa |

Impact Toughness (Charpy) | ~35 J (notched, room temp) |

The combination of tensile strength, hardness, and elongation ensures that P20 tool steel retains its dimensional integrity under high-stress, high-cycle operations.

Die Casting Mold Performance Characteristics

P20 tool steel offers several performance advantages for die casting molds:

Pre-hardened condition: Eliminates the need for additional hardening, reducing lead time and cost

Good machinability: Facilitates high-precision CNC machining and finishing operations

Thermal stability: Provides consistent cooling and temperature control for uniform casting quality

Durability: Excellent resistance to deformation and wear, making it ideal for high-volume die casting applications

At Neway’s tool and die facility, P20 is used in the production of:

Mold bases for aluminum and zinc alloy die casting

Ejector pins, core inserts, and support plates

Slides and runners in die-casting molds

Complex mold structures requiring dimensional stability

Common Applications

P20 tool steel is widely used in the following tooling applications:

Die casting: Mold bases for aluminum, zinc, and magnesium die casting

Plastic injection molding: Mold frames and core components

Precision tooling: For parts requiring tight tolerances and wear resistance

General tooling: For cutting, blanking, and stamping dies

Fixture and support components: Used in applications requiring consistent, reliable performance over time

Machining Advantages and Considerations

P20 tool steel is renowned for its excellent machinability, which makes it suitable for high-precision tooling:

Ease of machining: Can be easily CNC milled, drilled, and turned even in the pre-hardened condition

Minimal distortion: Pre-hardened structure ensures minimal distortion after machining

Polishability: Especially in P20+Ni grades, it can be polished to a high surface finish for optical-grade tooling

At Neway, P20 is machined using state-of-the-art CNC machines to achieve:

Tolerances within ±0.01 mm

Surface finishes as fine as Ra 0.8 µm

Fast turnaround time from design to production

Surface Treatment Compatibility

Although P20 is supplied in a pre-hardened state, it can be further enhanced by surface treatments to improve its performance:

Nitriding: Increases surface hardness and wear resistance without affecting core properties

PVD coatings: Provides additional wear resistance and improves part release properties

Cryogenic treatment: Enhances the steel’s toughness and reduces residual stresses for improved dimensional stability

These treatments significantly extend the life of tooling in high-cycle die casting or injection molding operations.

FAQs

How does P20 compare to H13 in terms of mold durability?

Can P20 be used in both die casting and plastic injection molding applications?

What is the recommended heat treatment cycle to achieve optimal performance from P20?

How does the addition of nickel affect the properties of P20 steel?

Can P20 steel be used for both structural and cutting applications in tooling?