Can beryllium copper be used for high-volume inserts?

Can Beryllium Copper Be Used for High-Volume Inserts?

Performance Characteristics of Beryllium Copper

Beryllium copper, especially in its hardened form (C17200), is widely used in high-performance die casting applications due to its excellent thermal conductivity, moderate hardness, and superior wear resistance. With thermal conductivity ranging from 105 to 130 W/m·K and tensile strength exceeding 1,300 MPa, it enables rapid heat dissipation, shorter cycle times, and dimensional stability in tooling components.

Unlike traditional tool steels, beryllium copper does not suffer from soldering with aluminum, making it highly effective in thermally stressed zones of aluminum and magnesium die casting tools.

Suitability for High-Volume Production

Beryllium copper is suitable for high-volume inserts when used strategically in the following cases:

Thin-wall casting zones requiring rapid solidification

Gate areas or core pins exposed to extreme localized heating

Inserts subject to high wear or soldering from molten alloys

However, full die cavities are not recommended due to the alloy’s lower hot strength compared to H13 and significantly higher cost. Machining precautions are also necessary to prevent exposure to beryllium particles.

Common Use Cases

Typical high-volume insert applications include:

Core pins in aluminum die casting molds

Gate inserts for magnesium and light alloy molds

Slides or lifters in multi-cavity tooling

Thin-section heat-concentrated areas in rapid-cycle tools

Recommended Services for Beryllium Copper Insert Applications

To ensure reliable mold performance in demanding high-volume environments, Neway provides:

Advanced Tooling Fabrication

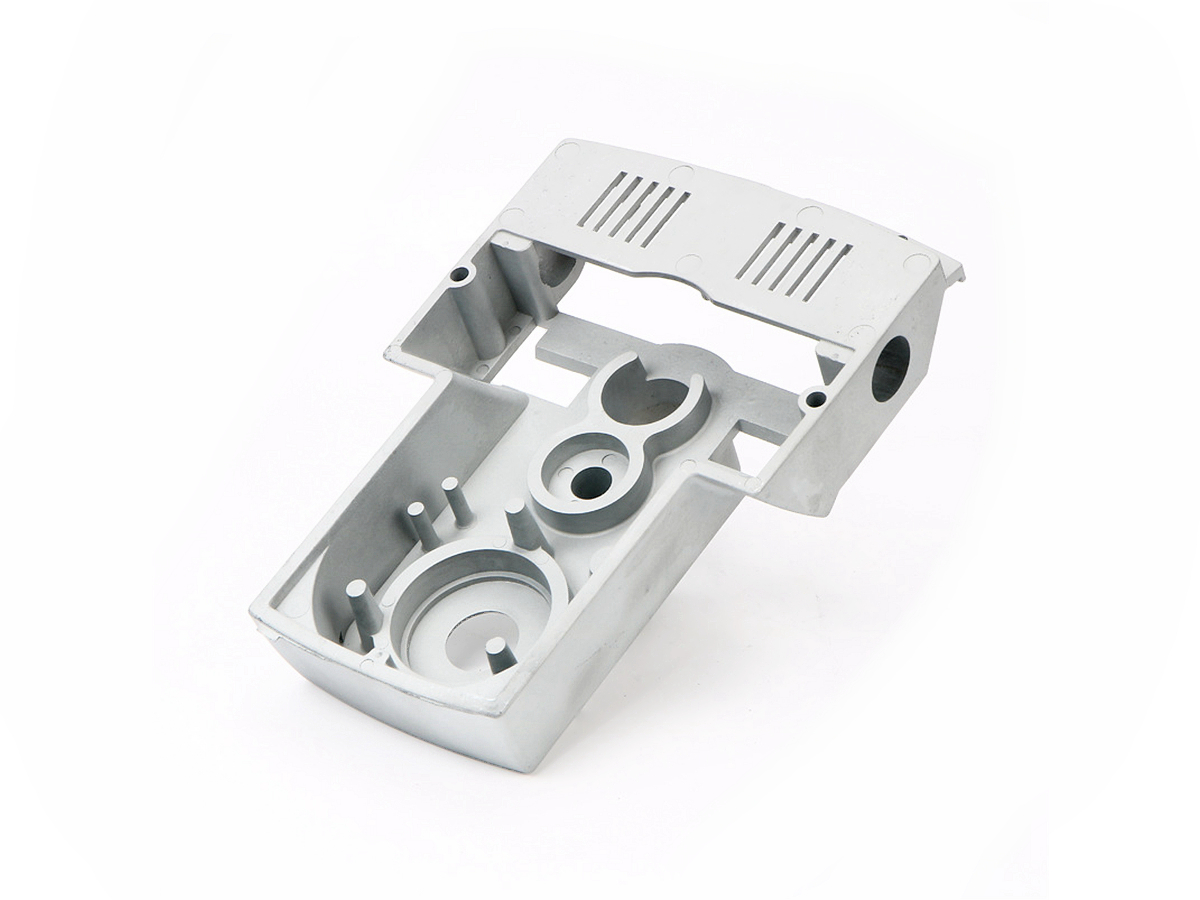

Tool and Die Making: Precision-built dies with integrated beryllium copper inserts for thermal efficiency.

Optimized Casting Production

Aluminum Die Casting: Efficient high-volume casting supported by thermally optimized tooling.

Engineering and Validation

Die Casting Engineering: Insert positioning, thermal flow modeling, and die wear simulation.

Rapid Prototyping: Tooling validation with insert performance testing in pre-production runs.

Our complete one-stop die casting service ensures optimal material integration and tooling lifespan, from design to final part production.