What is the best tool steel for aluminum die casting molds?

What Is the Best Tool Steel for Aluminum Die Casting Molds?

Key Criteria for Tool Steel Selection in Aluminum Die Casting

Tool steels for aluminum die casting molds must endure repeated exposure to molten aluminum at ~660°C, withstand thermal fatigue, resist erosion, and prevent soldering. The ideal tool steel should also provide dimensional stability during high-cycle production.

At Neway, we specialize in tool and die making using premium-grade steels optimized for aluminum die casting. Among all options, H13 tool steel is the industry benchmark, with several alternatives suited for specific use cases.

Top Tool Steel Options for Aluminum Die Casting

1. H13 Tool Steel

H13 steel is the most widely used hot-work tool steel for aluminum die casting molds. It offers a balance of:

High red hardness (~44–52 HRC)

Excellent thermal fatigue resistance

Good toughness and dimensional stability

Resistance to aluminum soldering

H13 meets NADCA #207 standards and supports mold life up to 100,000–150,000 shots with proper heat treatment and cooling.

2. H13X Modified Tool Steel

H13X is a modified variant designed for extended die life. It features enhanced microstructure stability and reduced risk of thermal cracking, especially in high-volume production.

3. A2 and D2 Tool Steels

A2 and D2 are cold-work steels used in low-pressure casting or inserts, but they lack the thermal shock resistance needed for high-pressure aluminum casting molds.

4. P20 Tool Steel

P20 steel is suitable for prototype or short-run die casting tools. It offers good machinability and polishability but is limited in thermal performance under continuous casting cycles.

5. Tungsten Carbide (for Inserts)

Tungsten carbide is used in critical insert areas where wear and erosion resistance is crucial—such as gate edges and die corners.

Recommended Die Casting Mold Solutions for Aluminum Projects

To maximize tool life and mold precision, we provide:

Tool and Mold Fabrication

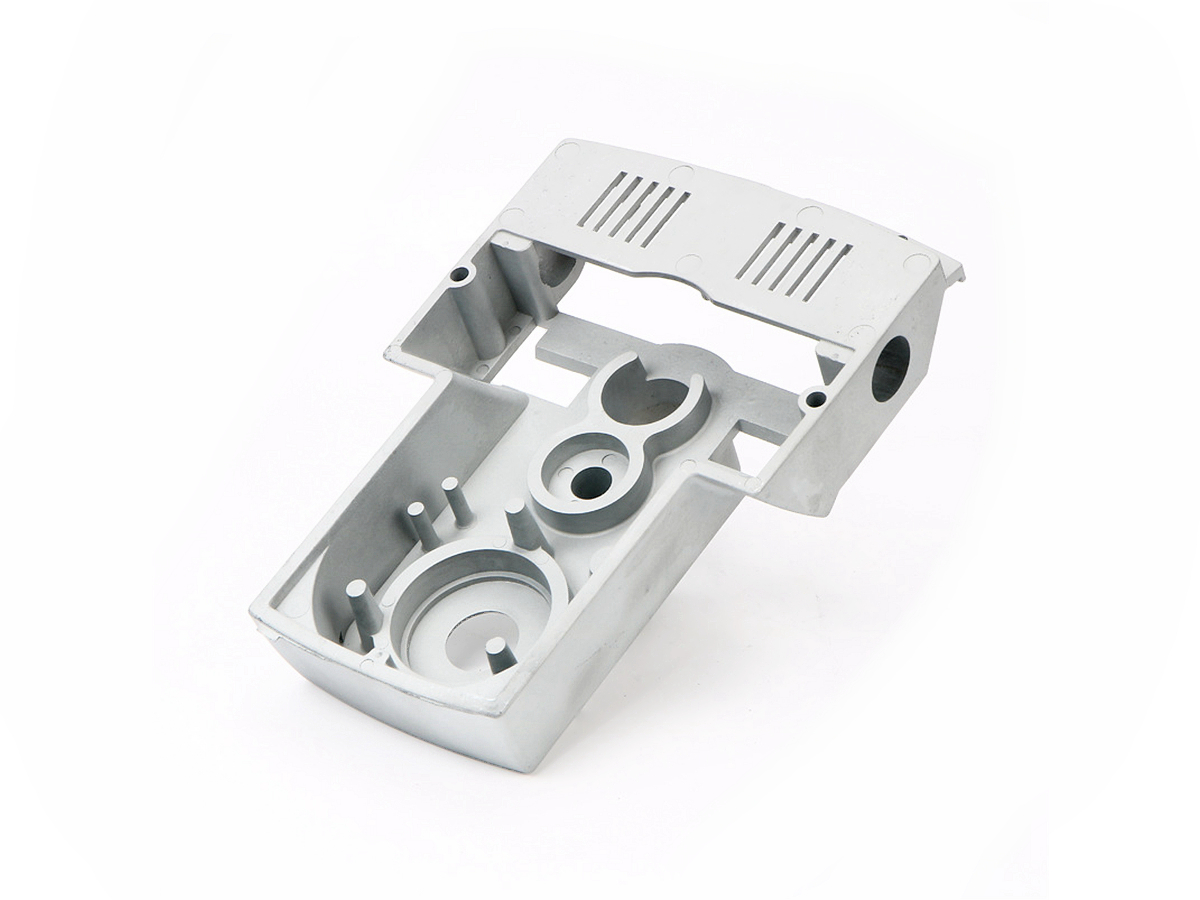

Tool and Die Making: Precision-built dies using H13 and other high-performance tool steels.

Die Casting Engineering: Optimize die design for heat management and cycle life.

Aluminum Die Casting Production

Aluminum Die Casting: High-volume casting using optimized tool steels for durability and efficiency.

Mold Validation and Sampling

Rapid Prototyping: Validate tool designs with pre-production trials before mass tooling investment.

Our one-stop die casting service ensures proper steel selection, mold design, casting execution, and part quality for your aluminum projects.