A2 Steel

Introduction to A2 Steel

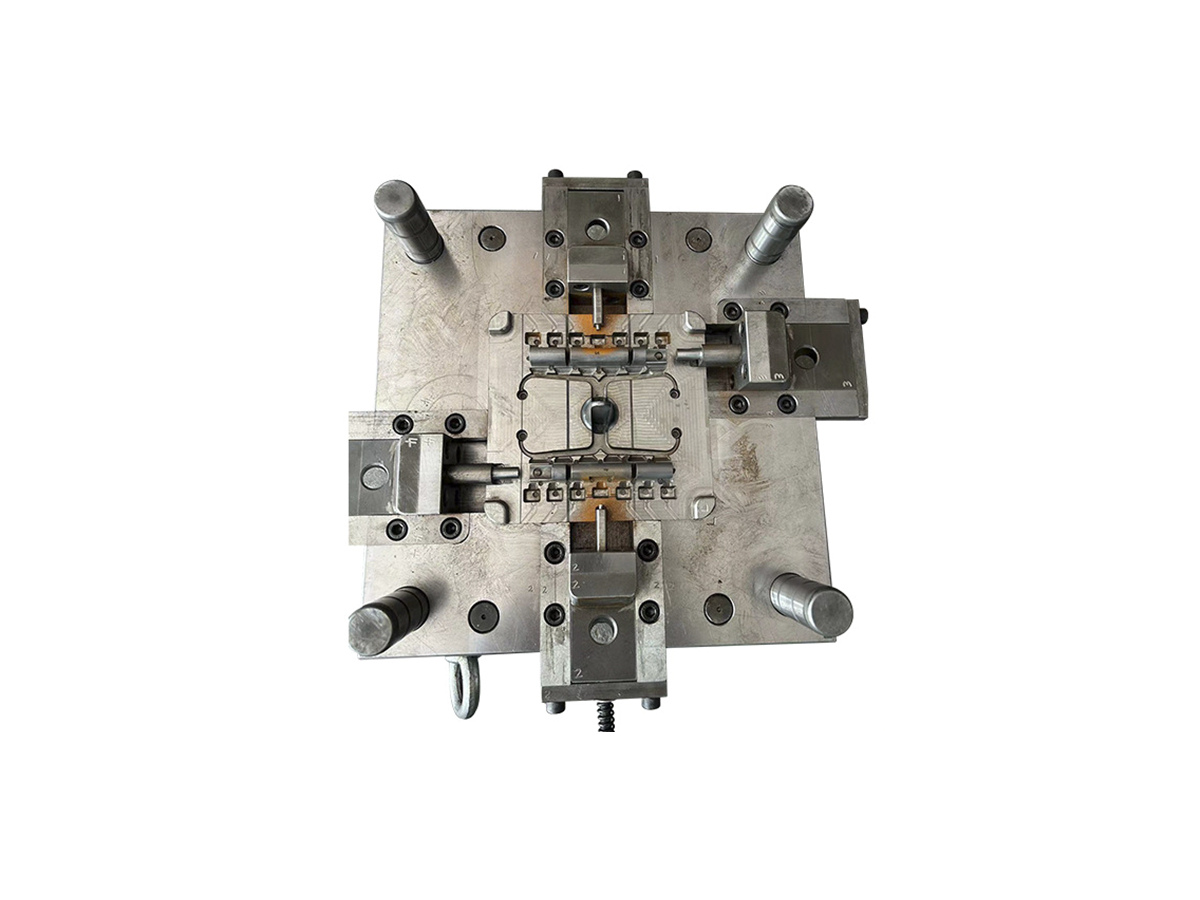

A2 is a medium-alloy, air-hardening cold-work tool steel known for its outstanding dimensional stability, balanced wear resistance, and moderate toughness. It is commonly used in blanking, forming, and trimming operations where precision and consistent tolerances, including die casting secondary tooling, are essential.

At Neway Die Casting, A2 steel is widely used in tooling applications such as trim dies, inserts, and punch systems where hardness and edge retention are required under medium thermal and mechanical stress.

A2 Steel Chemical Composition (Typical, per ASTM A681)

Element | Weight % | Function |

|---|---|---|

Chromium (Cr) | 4.75–5.5 | Enhances wear resistance and hardenability |

Molybdenum (Mo) | 0.9–1.4 | Strengthens steel at elevated temperatures |

Vanadium (V) | 0.15–0.5 | Refines grain and improves toughness |

Carbon (C) | 0.95–1.05 | Provides hardness and edge retention |

Manganese (Mn) | 0.5–1.0 | Improves strength and response to heat treatment |

Silicon (Si) | 0.2–0.5 | Improves tempering resistance |

Iron (Fe) | Balance | Base matrix metal |

A2’s air-hardening behavior minimizes distortion during heat treatment, a key factor in high-precision die components.

Physical Properties of A2 Tool Steel

Property | Value & Unit |

|---|---|

Density | ~7.87 g/cm³ |

Thermal Conductivity | 24 W/m·K |

Specific Heat Capacity | ~460 J/kg·K |

Coefficient of Thermal Expansion | ~10.5 µm/m·°C |

Electrical Resistivity | ~0.6 µΩ·m |

Hardenability | Uniform through 100 mm section (air quench) |

These properties make A2 ideal for tool components that require dimensional stability after heat treatment.

Mechanical Properties (Heat Treated to 58–62 HRC)

Property | Typical Value & Unit |

|---|---|

Tensile Strength | 1950–2100 MPa |

Yield Strength | ~1600 MPa |

Hardness | 58–62 HRC |

Impact Toughness (Charpy) | ~20–30 J |

Elongation | 3–5 % |

Modulus of Elasticity | ~210 GPa |

A2 offers an optimal combination of wear resistance and toughness for cold work applications that demand tight tolerances and long tool life.

Die Casting and Tooling Applications

While A2 is not typically used in hot work dies due to limited thermal fatigue resistance, it excels in cold-to-warm secondary tooling:

Trimming dies and punches for die-cast aluminum and zinc parts

Tooling inserts for gates, runners, and ejector systems

Fixture blocks and guide pins requiring low wear and high stability

Pre-machined mold components that undergo finishing or trimming

At Neway’s tool and die facility, A2 is used in trimming stations for mass production workflows requiring long-lasting precision tools.

Common Applications

A2 tool steel is used across multiple sectors due to its balance of properties:

Precision punch and die sets for cold stamping

Edge retainers, form tools, and shearing blades

Wear plates and gibs in die-cast part post-processing

Trim dies for aluminum alloy castings

Injection mold inserts operating at room to moderate temperature

Machining Challenges and Solutions

A2 is relatively easy to machine in the annealed condition but becomes harder post-hardening:

Rough machining should be done before heat treatment to prevent tool wear

Post-hardening operations typically involve grinding or EDM

Tool path planning must account for hardness zones when milling hardened A2

At Neway, we utilize CNC machining and EDM finishing to achieve:

Surface finishes down to Ra 0.8 µm

Dimensional accuracy within ±0.01 mm

High-repeatability die trimming systems for aluminum and zinc castings

Surface Treatment Compatibility

A2 steel supports several enhancement techniques to extend die life:

Nitriding to boost surface hardness without affecting core strength

PVD coatings (e.g., TiN, TiCN) for anti-friction and wear protection

Cryogenic treatment to increase dimensional stability and reduce residual stress

These treatments make A2 suitable for high-volume trimming or blanking operations with minimal maintenance downtime.

FAQs

How does A2 compare to D2 and S7 in die trimming applications?

Can A2 be used in warm or low-thermal-load casting operations?

What is the best heat treatment cycle for achieving 60 HRC in A2 dies?

How dimensionally stable is A2 after quenching and tempering?

Is A2 suitable for combination tools involving both shearing and forming?