D2 Steel

Introduction to D2 Steel

D2 is a high-carbon, high-chromium cold-work tool steel offering exceptional wear resistance, compressive strength, and dimensional stability. Its rich alloy composition enables long die life under high-cycle, high-abrasion conditions. It is ideal for blanking dies, trimming tools, and inserts used in aluminum and zinc die casting.

At Neway Die Casting, D2 is selected for tooling components exposed to intense wear, ensuring consistent edge retention, minimal deformation, and reduced downtime across high-volume production environments.

D2 Steel Chemical Composition (Typical, per ASTM A681)

Element | Weight % | Function |

|---|---|---|

Chromium (Cr) | 11.0–13.0 | Primary contributor to wear and corrosion resistance |

Carbon (C) | 1.40–1.60 | Provides high hardness and compressive strength |

Molybdenum (Mo) | 0.7–1.2 | Enhances secondary hardening and toughness |

Vanadium (V) | 0.1–0.3 | Improves wear resistance and grain refinement |

Manganese (Mn) | 0.2–0.6 | Enhances hardenability |

Silicon (Si) | 0.1–0.6 | Improves temper resistance |

Iron (Fe) | Balance | Base matrix |

The high chromium content enables secondary hardening and provides resistance to softening during tempering, even at elevated temperatures.

Physical Properties of D2 Tool Steel

Property | Value & Unit |

|---|---|

Density | ~7.7 g/cm³ |

Thermal Conductivity | 20–22 W/m·K |

Specific Heat Capacity | ~460 J/kg·K |

Coefficient of Thermal Expansion | 10.5–11.2 µm/m·°C |

Electrical Resistivity | ~0.6 µΩ·m |

Decarb-Free Depth (hardened) | ≥ 2 mm |

These properties support dimensional stability in post-heat treatment operations, even with fine-featured components.

Mechanical Properties (Heat Treated to 58–62 HRC)

Property | Typical Value & Unit |

|---|---|

Tensile Strength | 1900–2100 MPa |

Yield Strength | ~1600 MPa |

Hardness | 58–62 HRC |

Compressive Strength | >2300 MPa |

Impact Toughness (Charpy) | 10–20 J |

Modulus of Elasticity | ~210 GPa |

D2 achieves very high hardness and edge retention while maintaining structural integrity under high-pressure contact in die trims or punches.

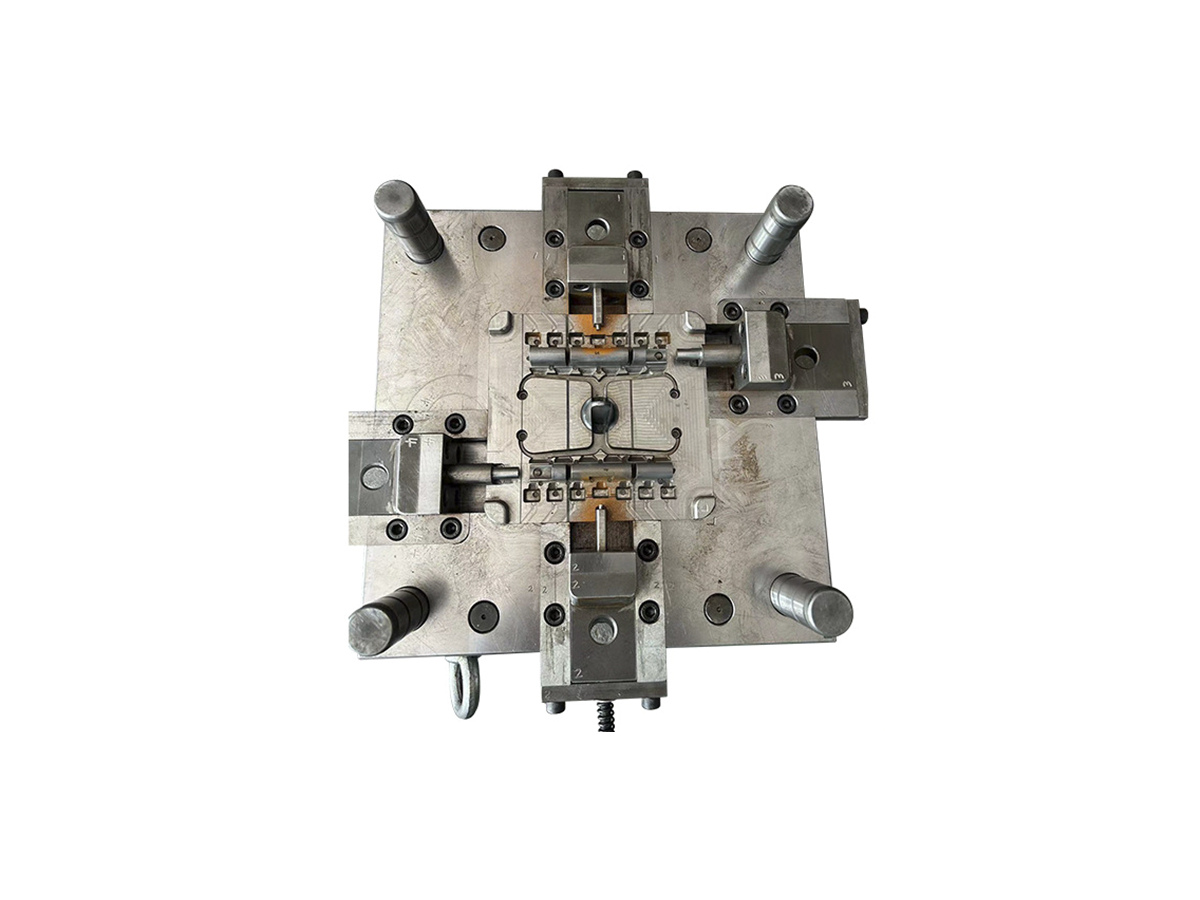

Die Casting and Tooling Suitability

D2 is particularly suitable for:

Edge-forming inserts and trimming dies

Cutting punches for flash removal in zinc and aluminum die castings

Guide pins and wear strips for mass production tooling

Sliders and bushings operating under abrasive contact

Blanking or shearing dies where minimal wear is acceptable over long cycles

Its abrasion resistance makes it ideal for post-casting operations, especially in automated die trimming systems.

Common Applications

Thanks to its resistance to galling, abrasion, and high compressive stress, D2 is widely used in:

Die casting post-process stations for trimming and blanking

Fine edge punches and high-pressure inserts

Wear-resistant dowels, bushings, and fixture parts

Cold-forming and stamping dies

Injection mold gates exposed to high-fiber-fill polymers

Machining Challenges and Solutions

Due to its hardness and chromium content, D2 is more difficult to machine than A2 or P20:

Annealed condition (~225 HB) is optimal for rough machining

Requires high-rigidity setups and coated carbide tooling

Post-hardening operations include grinding and EDM only

At Neway, D2 is machined with:

CNC-controlled roughing and finishing in staged heat treatment

Wire EDM to ensure dimensional accuracy on hardened profiles

Final tolerances within ±0.01 mm and surface finish down to Ra 0.6 µm

Surface Treatment Compatibility

D2’s alloy matrix accepts multiple hardening and coating treatments:

Nitriding to add a tough surface layer without reducing core strength

PVD coatings (TiCN, AlTiN) to further resist galling and friction

Cryogenic treatment to stabilize martensitic structure and reduce retained austenite

These enhancements extend die life especially in automated or unattended die cutting environments.

FAQs

How does D2 steel compare to A2 and S7 in wear resistance and toughness?

What is the best heat treatment cycle to achieve full hardness in D2 tooling?

Can D2 be used for both die casting and plastic injection trimming?

How dimensionally stable is D2 after high-temperature tempering?

Is D2 suitable for EDM machining of small inserts?