How precise are threads and seals in cast brass pipe fittings?

How Precise Are Threads and Seals in Cast Brass Pipe Fittings?

Precision Requirements for Brass Pipe Threads and Sealing Surfaces

Brass pipe fittings require high precision in both threads and sealing surfaces to ensure leak-tight connections under pressure. At Neway Die Casting, cast brass fittings—especially those made from alloys like C84400 Semi-Red Brass or Brass 464—undergo post-machining processes that achieve tight tolerances and sealing reliability conforming to ISO, ANSI, and ASME standards.

Thread Accuracy and Standards

Neway uses high-precision CNC post-machining to cut threads on cast fittings. The result is high conformity to thread standards such as:

NPT (ANSI B1.20.1): Tapered pipe threads used for pressure-tight sealing via metal-to-metal interference

BSPT/BSPP (ISO 7/1, ISO 228): Metric pipe threads for international plumbing systems

G-thread (DIN EN ISO 228-1): Parallel threads with gaskets or O-rings for sealing

Thread tolerances are typically held to ±0.05 mm, ensuring reliable torque engagement and repeatable assembly.

Flatness and Surface Finish of Sealing Faces

Sealing surfaces on brass fittings—such as flange faces, O-ring grooves, and compression zones—are machined to achieve:

Flatness Tolerances: ≤0.05 mm for mating faces

Surface Roughness (Ra): 0.8–1.6 µm, depending on sealing method (gasket, elastomer, or metal-to-metal)

These characteristics reduce leak risk, especially in pressurized plumbing and HVAC systems.

Testing and Quality Assurance

All machined fittings are inspected using:

Thread gauges (Go/No-Go) for conformity

Surface profilometers for sealing finish control

Pressure and leakage tests based on ISO 5208 and ASME B16.15

These tests verify that fittings maintain integrity under water, gas, or steam applications.

Typical Applications of High-Precision Brass Fittings

Residential and commercial plumbing systems

HVAC manifolds and couplers

Fire protection and irrigation lines

Water meters and backflow preventers

Customer-Oriented Precision Brass Solutions

Neway Die Casting ensures exact fit and sealing reliability with:

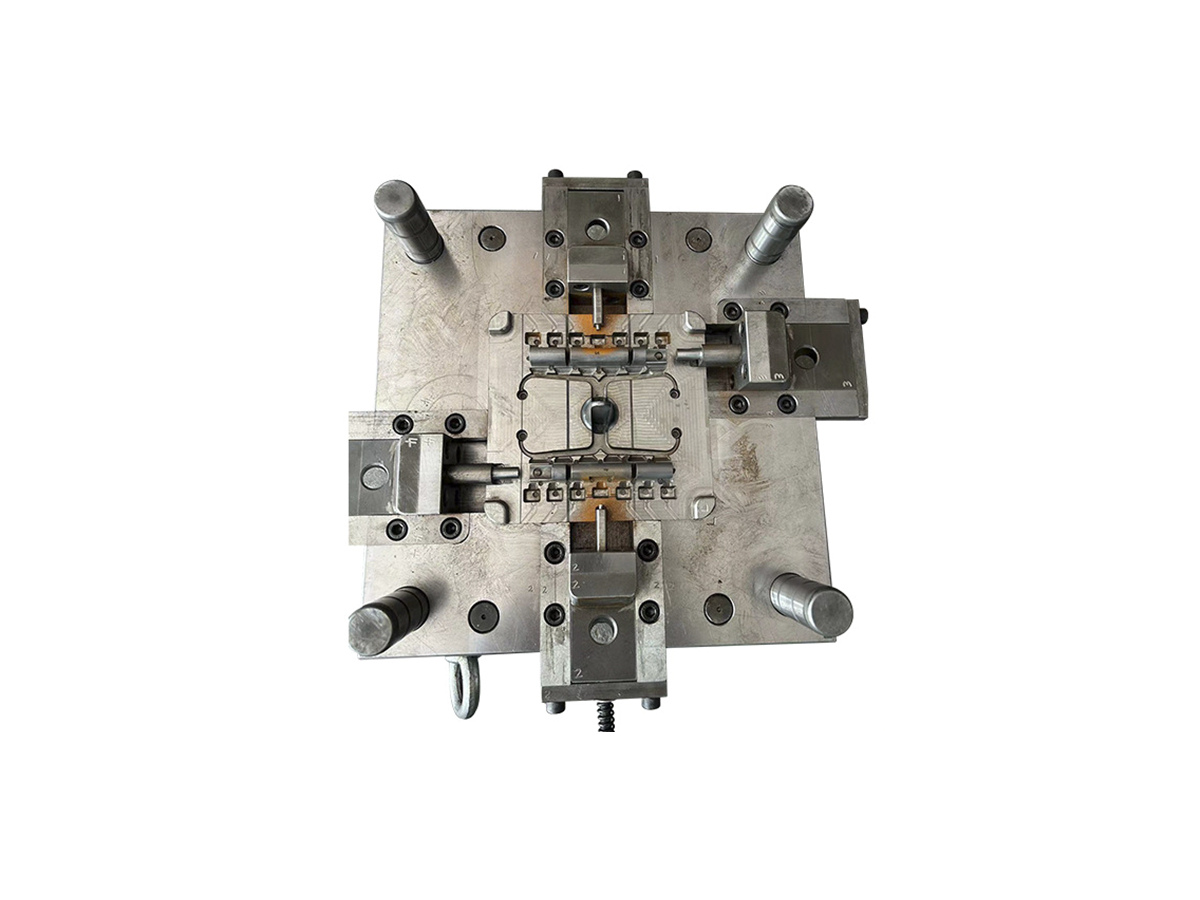

Brass Die Casting Services: Reliable castings for threaded and sealed plumbing components

Post-Machining Services: CNC machining of threads, flanges, and sealing faces to global standards

Inspection and Testing Equipment: Complete dimensional and pressure test validation for brass fittings