Leaded Free-Cutting Brass C48500

Material Introduction

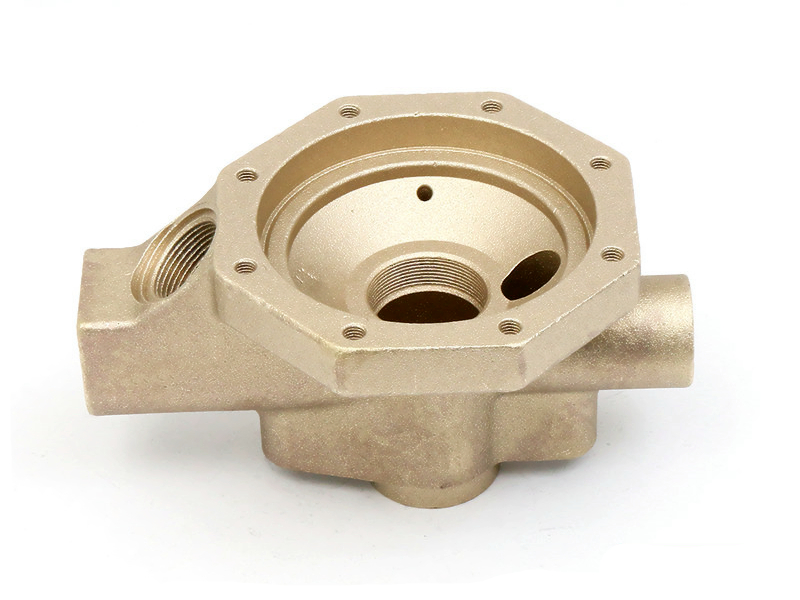

Leaded Free-Cutting Brass C48500 is a high-performance copper alloy specifically engineered for superior machinability in copper die casting and subsequent machining operations. This alloy features a controlled lead content that significantly enhances chip formation and tool life, making it the ideal choice for high-volume production of complex components that require extensive post-casting machining. C48500 offers an excellent balance of good mechanical properties, corrosion resistance, and wear characteristics, alongside its unparalleled free-cutting capability. When processed with Neway's advanced tool and die making expertise and precision post-machining services, it delivers exceptional dimensional stability and production efficiency for plumbing fixtures, precision gears, electrical connectors, and other intricate parts.

Alternative Material Options

For applications where lead-free compliance is mandatory, Silicon Brass C87850 offers excellent machinability without the use of lead. If higher strength and corrosion resistance are required, Aluminum Bronze C95400 is a robust alternative. For general-purpose brass die casting with good overall properties, Brass 360 is a widely available option. When superior thermal and electrical conductivity are the primary concerns, C17500 copper alloy may be selected. For cost-sensitive applications that still require good machinability, Brass 380 provides a balanced solution. In non-copper alternatives, high-strength Zamak 5 zinc alloy or lightweight A380 aluminum alloy can be considered, as their respective properties align with the application needs.

International Equivalent / Comparable Grade

Country/Region | Equivalent / Comparable Grade | Specific Commercial Brands | Notes |

USA (ASTM/UNS) | C48500 (Leaded Brass) | Mueller Brass C48500, PMX C48500, Concast C48500 | Standard UNS designation for high-leaded brass rod and cast products. |

Europe (EN) | CuZn39Pb3 (CW617N) | KME CW617N, Wieland CuZn39Pb3, Luvata CW617N | Common European leaded brass equivalent with similar machinability. |

Japan (JIS) | C6782 / C6783 | JX Nippon C6782, Mitsubishi Shindoh C6783 | Japanese leaded brass grades with comparable free-cutting performance. |

Germany (DIN) | Ms60 (CuZn39Pb3) | Diehl Metall Ms60, Aurubis Ms60 | German specification matching EN CW617N composition. |

China (GB/T) | HPb60-2 / HPb59-2 | Ningbo HPb60-2, Zhongse HPb59-2 | Chinese leaded brass grades with similar lead content and properties. |

UK (BS) | CZ121 / CW617N | Luvata CZ121, Aalco CW617N | British standards aligned with European CW617N specifications. |

International (ISO) | CuZn39Pb3 | Various ISO-certified foundries and mills | International standard grade equivalent to European CW617N. |

Design Purpose

C48500 was specifically formulated to meet the demanding requirements of high-speed, precision machining of brass components, where extended tool life and excellent surface finish are critical. The intentional lead addition creates discontinuous chips that prevent built-up edge on cutting tools, significantly reducing machining forces and heat generation. This design purpose makes it ideal for manufacturing intricate parts with tight tolerances, deep drilling operations, and complex threading—all while maintaining good pressure-tightness and corrosion resistance typical of brass alloys. Its development aimed to maximize production throughput and minimize manufacturing costs for components requiring extensive secondary operations after the metal casting process.

Chemical Composition

Element | Copper (Cu) | Zinc (Zn) | Lead (Pb) | Iron (Fe) | Other Elements |

Composition (%) | 58.0-61.0 | Balance | 1.5-2.5 | ≤0.4 | ≤0.5 total |

Physical Properties

Property | Density | Melting Range | Thermal Conductivity | Electrical Conductivity | Thermal Expansion |

Value | 8.5 g/cm³ | 885-900°C | 115 W/m·K | 26% IACS | 20.5 μm/m·°C |

Mechanical Properties

Property | Tensile Strength | Yield Strength (0.5%) | Elongation | Hardness | Machinability Rating |

Value | 340 MPa | 140 MPa | 25% | 75 HB | 100% (Free-Cutting) |

Key Material Characteristics

Excellent free-cutting characteristics with 100% machinability rating.

Superior chip formation prevents long, stringy chips during machining.

Good corrosion resistance in freshwater and atmospheric environments.

Maintains pressure tightness suitable for plumbing and hydraulic applications.

Good wear resistance and anti-galling properties for moving components.

Features an attractive gold-like appearance, ideal for decorative hardware applications.

Excellent castability with good fluidity and minimal shrinkage porosity.

Capable of maintaining tight tolerances during high-volume production.

Compatible with all common post-processing techniques.

Extended tool life reduces manufacturing costs for machined components.

Manufacturability And Post Process

Copper Die Casting: Primary process for high-volume production of C48500 components.

Post Machining: Excellent machinability enables high-speed drilling, tapping, and milling.

CNC Machining: Ideal for complex geometries with tight tolerances (±0.025 mm).

Thread Cutting and Tapping: Produces clean, precise threads with minimal tool wear.

Drilling and Boring: Capable of deep hole drilling with excellent chip clearance.

Tumbling: Effective for deburring and achieving uniform edge radiusing.

Sand Blasting: Creates uniform matte surface texture for aesthetic or functional purposes.

Suitable Surface Treatment

Polishing and Buffing: Achieves a high-luster mirror finish for decorative applications.

Clear Lacquering: Preserves natural brass appearance while preventing tarnishing.

Electroplating: Compatible with nickel, chrome, and gold plating for enhanced appearance.

Powder Coating: Provides durable, colored finishes with proper surface preparation.

Antique Patina: Chemical treatments create the appearance of aged or vintage effects.

Passivation: Chemical treatment enhances tarnish resistance while maintaining metallic look.

Common Industries and Applications

Plumbing fixtures, valve bodies, and water distribution components.

Electrical connectors, terminals, and switchgear components.

Precision gears, bearings, and bushings for mechanical assemblies.

Architectural hardware, door handles, and decorative fittings.

Musical instrument components and mechanical parts.

Firefighting equipment and industrial valve applications.

Lock mechanisms and security hardware components.

When to Choose This Material

High-volume machining applications: Significantly reduces machining time and extends tool life.

Complex threaded components: Produces clean, precise threads with minimal tapping effort.

Plumbing and fluid handling systems: Offers excellent corrosion resistance and pressure tightness.

Decorative hardware with machining requirements: Combines aesthetic appeal with manufacturability.

Electrical components needing good conductivity: Provides 26% IACS electrical conductivity.

Wear-resistant moving parts: Good anti-galling properties for bearings and bushings.

Cost-sensitive precision parts: Reduces overall manufacturing costs through improved machinability.