Cast Iron

Introduction to Cast Iron

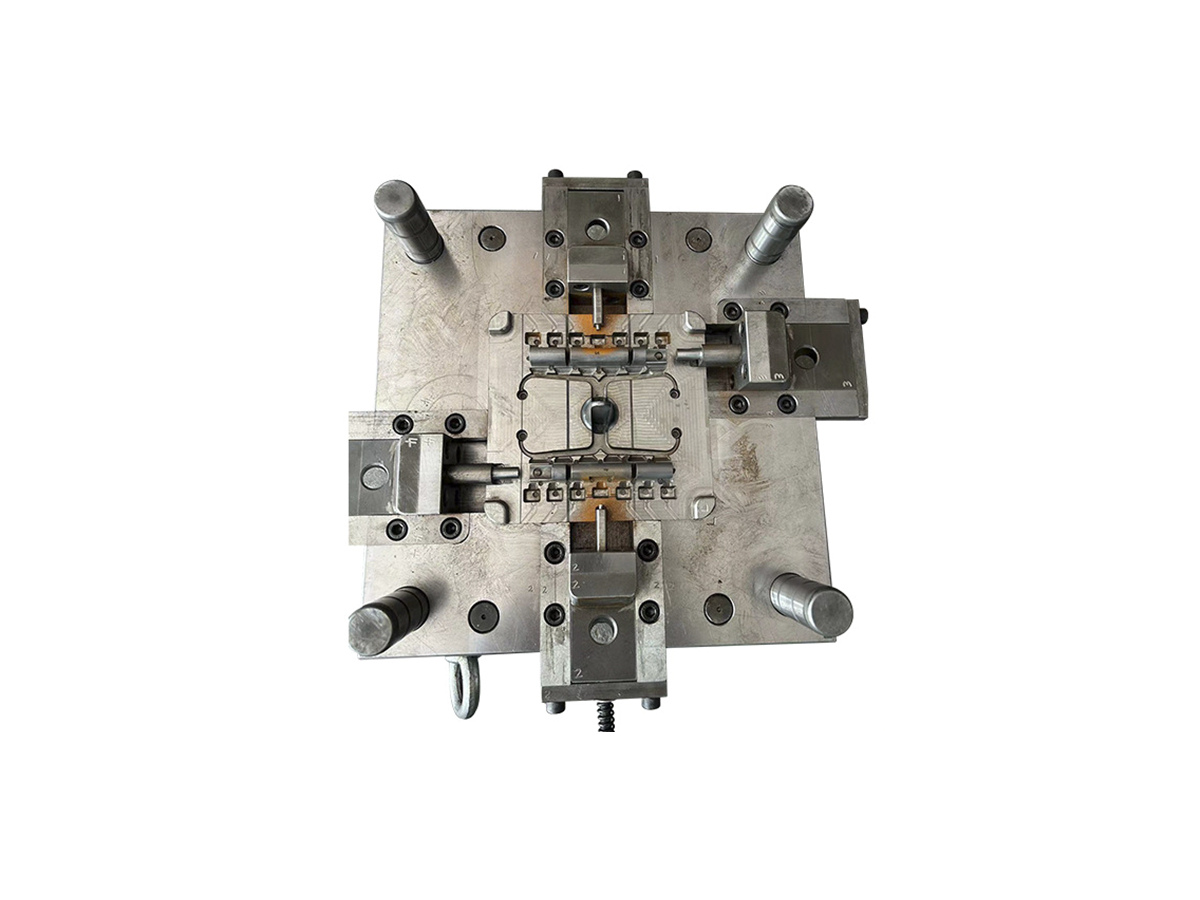

Cast iron is a group of iron-carbon alloys with a carbon content above 2.0%, primarily used in tooling, mold bases, and structural frames. Known for its compressive strength, vibration-damping, and dimensional stability, cast iron remains a cornerstone material in mold manufacturing and heavy equipment components.

At Neway Die Casting, cast iron is used extensively in tool base production and die-casting support components, offering an economical and durable solution with excellent thermal capacity and wear resistance.

Cast Iron Chemical Composition (Typical Gray Iron - ASTM A48 Class 40)

Element | Weight % | Function |

|---|---|---|

Carbon (C) | 3.2–3.5 | Forms graphite structure, enhances castability |

Silicon (Si) | 1.8–2.4 | Promotes graphite formation, improves machinability |

Manganese (Mn) | 0.6–0.9 | Enhances strength and hardness |

Phosphorus (P) | ≤ 0.15 | Improves fluidity but reduces ductility |

Sulfur (S) | ≤ 0.12 | Improves machinability, may reduce toughness |

Iron (Fe) | Balance | Primary matrix material |

Physical Properties of Cast Iron

Property | Value & Unit |

|---|---|

Density | 7.1 g/cm³ |

Thermal Conductivity | 52–60 W/m·K |

Specific Heat Capacity | 500 J/kg·K |

Coefficient of Thermal Expansion | 10.5–12 µm/m·°C |

Electrical Conductivity | ~10 % IACS |

Melting Point | 1150–1300 °C |

Its thermal mass and conductivity make cast iron ideal for die shoes and machine bases that experience heat cycling.

Mechanical Properties (Gray Iron, Class 40)

Property | Typical Value & Unit |

|---|---|

Compressive Strength | >700 MPa |

Tensile Strength | 270 MPa |

Hardness | 180–220 HB |

Modulus of Elasticity | 100–120 GPa |

Damping Capacity | High |

Elongation | 0–1 % |

Cast iron's strength and vibration-damping performance make it ideal for structural rigidity in dynamic equipment.

Casting Characteristics of Cast Iron

Cast iron has been an industry standard in sand casting due to its fluidity, ease of molding, and cost-effectiveness:

Excellent fluidity allows for complex mold geometries

Good wear resistance with embedded graphite lubricity

High thermal shock resistance for die base applications

Uniform shrinkage ensures dimensional reliability

At Neway’s tool and die facility, cast iron is selected for its machinability and stability in large mold and fixture bases.

Common Applications

Cast iron is a preferred material for static structural and tooling components across multiple industries:

Mold base plates and die shoes

Machine tool beds and equipment housings

Pump bodies, valve components

Engine cylinder liners and brake rotors

Counterweights and flywheels in automotive and heavy equipment

Machining Challenges and Solutions

Although cast iron is widely machinable, it introduces unique technical challenges:

Graphite flakes create abrasive wear on cutting tools

Brittle microstructure requires vibration control during milling

Dust generation can affect CNC equipment over time

Neway applies precision machining techniques tailored for cast iron, including:

Use of ceramic or CBN tools for enhanced durability

Negative rake angles to stabilize cutting action

High-pressure coolant systems to manage chip removal and dust

Tolerances within ±0.02 mm can be maintained on large surface areas with finish quality up to Ra 1.6 µm.

Surface Treatment Compatibility

Though typically used uncoated, cast iron may receive finishing treatments to improve corrosion and surface performance:

Oil impregnation or phosphate treatment for wear surfaces

Painting and powder coating for exterior durability

Induction hardening of bearing or wear surfaces

FAQs

What grades of cast iron are best for die base applications?

How does cast iron compare to tool steels like P20 or H13?

Can cast iron be heat treated for increased wear resistance?

What is the best way to machine large cast iron components?

Are there corrosion-resistant alternatives to traditional cast iron?