Complete Design-to-Manufacturing Support for Custom Components and Parts

Introduction

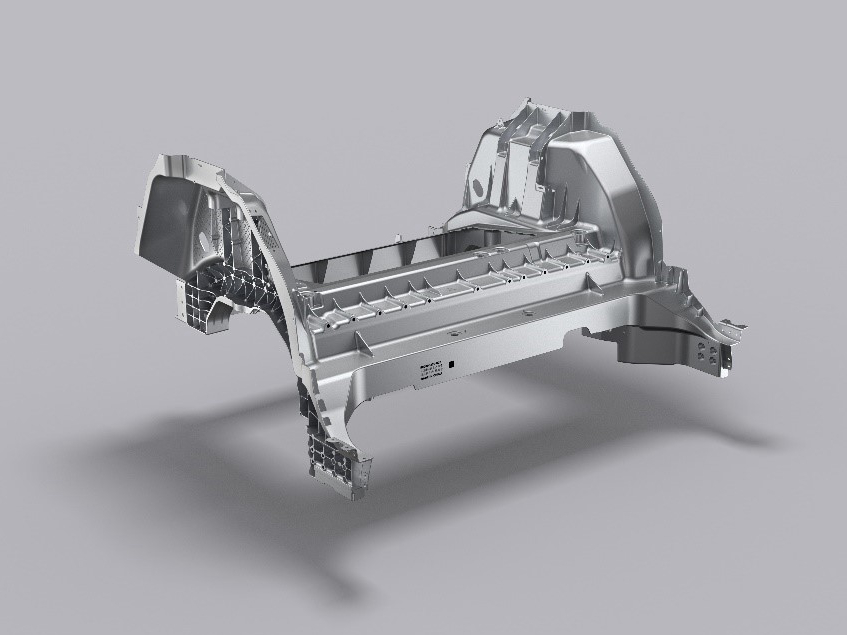

In today’s fast-paced, innovation-driven markets, transitioning from concept to completed component demands an integrated, efficient design-to-manufacturing workflow. At Neway, we provide comprehensive support for custom component development, incorporating detailed design review, precise material selection, rapid prototyping, and scalable mass production. Our integrated approach helps clients accelerate timelines, reduce manufacturing costs, and achieve stringent industry performance standards.

What Is Design-to-Manufacturing Support?

Design-to-manufacturing (DTM) support is a seamless, systematic process guiding your product from initial CAD drawings to the final manufactured components. Key advantages include streamlined communication, quicker iterative cycles, and thorough optimization for manufacturability, functionality, and cost-effectiveness.

Key stages include:

Design optimization (DFM - Design for Manufacturability, DFA - Design for Assembly)

Material selection based on ASTM, ISO, and other industry standards

Prototype development via CNC machining, die casting, or additive manufacturing

Iterative validation with precise tolerance verification

Tooling and fixture design and validation

Mass production, in-line inspection, and detailed post-processing

Why Choose an Integrated DTM Partner?

Feature | Benefit |

|---|---|

Unified technical support | Reduced handoffs between design, tooling, and manufacturing teams |

Faster time-to-market | Average reduction of project timelines by up to 25–30% |

Cost-effective solutions | Early-stage optimization minimizes expensive design revisions |

Improved scalability | Seamless scaling from prototypes (5–50 units) to mass production (100,000+ units) |

Real-time engineering feedback | Rapid adjustments to design and material specifications |

Design and Engineering Services

Our in-house engineering support includes comprehensive evaluation services:

2D to 3D CAD conversion and validation per ISO 10303 (STEP) standards

DFM analysis: optimization of wall thicknesses (minimum recommended: aluminum ≥ 1.5 mm, zinc ≥ 0.8 mm), draft angles (standard 1–3°), and tolerance stack-ups (±0.05 mm standard)

Finite Element Analysis (FEA) compliant with ISO 9001 and ASME standards to assess stress (up to 400 MPa), thermal distribution, and vibration resistance

ASTM-based material recommendations, ensuring compliance with required tensile strength, thermal conductivity, corrosion resistance, and cost-efficiency parameters

For example, during a custom sensor enclosure project, we achieved a 12% weight reduction by optimizing rib geometry and switching from A360 aluminum (tensile strength ~317 MPa) to AlSi12 (tensile strength ~240 MPa, superior castability), meeting the client’s performance and budget goals.

Rapid Prototyping and Pre-Production Validation

We utilize advanced prototyping methods:

SLA/SLS 3D printing technologies with dimensional accuracy of ±0.1–0.3 mm, ideal for initial visual validation

CNC machining prototypes capable of achieving tolerances down to ±0.005 mm, delivered within 3–7 business days

Soft tooling options (P20 steel) suitable for batch sizes of 50–500 units, ready within 10–20 days

Urethane casting for limited pre-production testing runs (typically under 100 units), achieving dimensional accuracy of ±0.25 mm

These prototyping services enable rapid feedback and design iterations, significantly reducing overall development lead times.

Tooling Design and Production Readiness

Neway offers robust tooling solutions, ensuring readiness for high-volume manufacturing:

Die-cast tooling made from P20 and H13 steel, capable of 300,000 to 500,000 production cycles

Multi-cavity molds (2–8 cavities standard), reducing per-unit cycle times (typically 20–60 seconds per shot)

Modular tooling systems facilitating rapid adjustments for product variations within days

Mold-flow analysis compliant with ASTM D6204 for die-cast filling patterns, venting optimization, and minimizing porosity below industry-standard (≤ 0.5%)

Material and Process Specifications

Selecting optimal materials and processes according to ASTM and ISO standards ensures performance and cost control:

Common Materials

Aluminum Alloys:

A380 aluminum (ASTM B85, tensile strength ~324 MPa, thermal conductivity ~96 W/m·K)

AC8A aluminum (JIS H5302, tensile strength ~320 MPa, excellent corrosion resistance)

AC4C aluminum (JIS H5302, tensile strength ~275 MPa, thermal conductivity ~120 W/m·K)

Zinc Alloys:

Copper Alloys:

Brass 360 (ASTM B16, tensile strength ~345 MPa, corrosion-resistant)

C18200 copper (ASTM B441, electrical conductivity ~80% IACS, ideal for electrical components)

Production Processes

Die casting: capable of high-volume production (50,000–1,000,000+ parts/year), tolerances ±0.1 mm standard

CNC machining: precision features achievable to ±0.005 mm, surface finishes down to Ra 0.8 µm

Post-processing: anodizing thickness per MIL-A-8625 Type II (10–25 µm), powder coating per ASTM D3451 (60–100 µm thickness)

Assembly services: meeting IPC-A-610 and ISO 9001 standards, comprehensive QA and documentation support

Conclusion

Effective custom component development requires integrated engineering, precise validation, and scalable manufacturing. Neway’s comprehensive design-to-manufacturing support ensures products achieve industry-leading standards in quality, precision, and efficiency from the outset.

Partner with Neway to accelerate your component development journey, from concept through mass production, with consistent reliability and industry-leading performance.

FAQs

What CAD formats does Neway accept for custom component manufacturing?

How fast can CNC-machined prototypes be produced at Neway?

Can Neway’s tooling accommodate large-scale production runs exceeding 100,000 units per year?

What quality control and inspection standards does Neway follow?

Does Neway provide comprehensive documentation, including compliance certificates, for production batches?