ADC1

Material Introduction

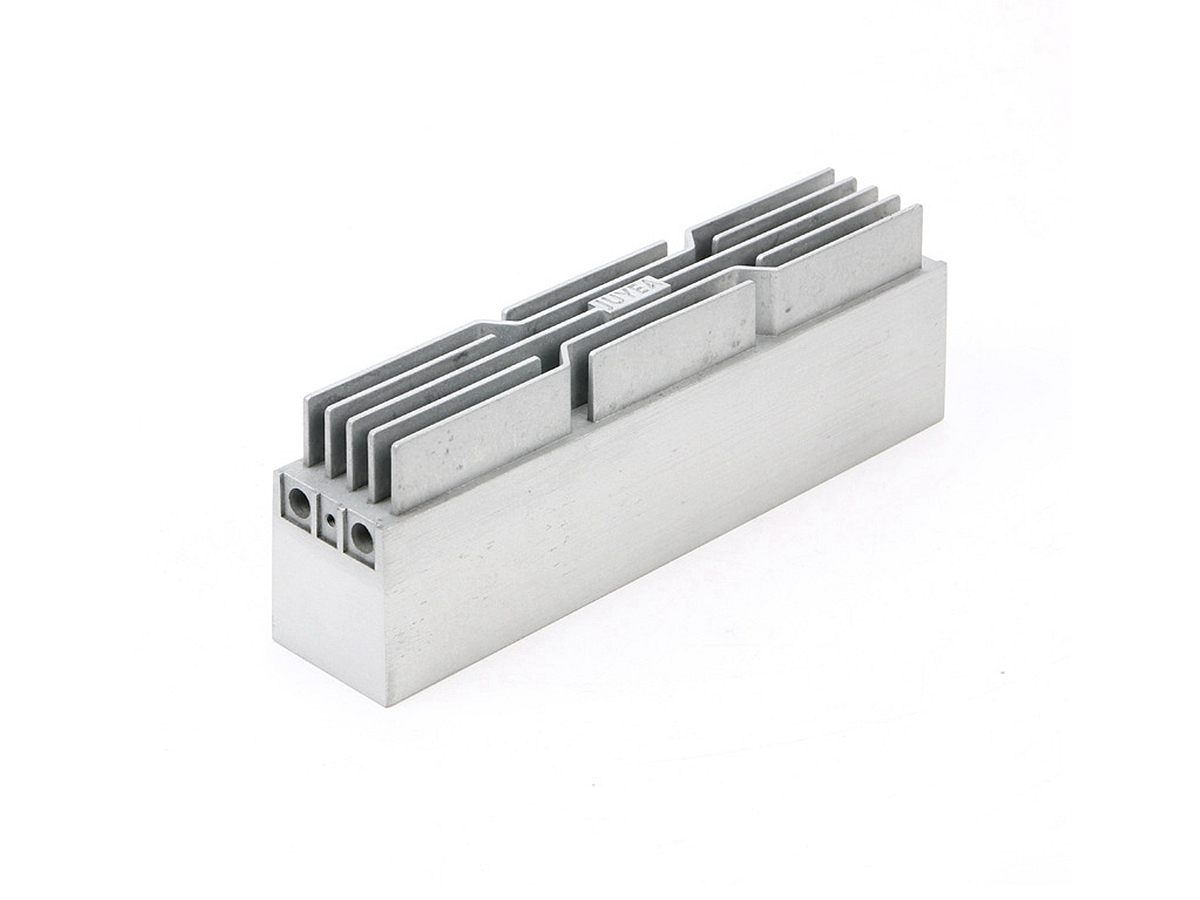

ADC1 is a high-purity aluminum casting alloy widely used for precision, lightweight components that demand excellent corrosion resistance, stable mechanical performance, and exceptional dimensional accuracy. As a low-impurity, low-copper alloy, ADC1 offers superior corrosion stability and a reduced risk of internal porosity compared to copper-rich aluminum die-casting alloys. This makes it ideal for high-end electronic housings, communication device frames, optical equipment mounts, small structural brackets, and components that require excellent electrical insulation without compromising mechanical integrity. When produced through Neway’s optimized aluminum die casting, refined gating control, and advanced tool and die making, ADC1 achieves smooth surfaces, stable microstructures, and reliable thin-wall performance for consumer electronics and precision mechanisms.

Alternative Material Options

For higher strength and rigidity, AlSi7Mg or AlSi10Mg provide significantly higher tensile and fatigue performance. If improved castability or complex thin-wall filling is required, ADC12 / A383 offers superior flow characteristics. For applications needing better thermal stability or strength at elevated temperatures, A380 is a more suitable substitute. For premium aesthetics or higher conductivity, Brass 380 and copper-brass alloys may be considered for non-aluminum solutions.

International Equivalent / Comparable Grade

Country/Region | Equivalent / Comparable Grade | Commercial Brands | Notes |

Japan (JIS) | ADC1 | Daiki ADC1, UACJ ADC1 | Original grade, widely used for precise electronic housings. |

USA (AA) | 1100-series cast equivalents | Kaiser 1100 cast, Belmont 1100 | Close chemical family with high purity. |

Europe (EN) | Al99.x series (varies) | Hydro Al99 series | Used for high corrosion resistance and electrical components. |

China (GB/T) | ZL101A (high-purity variants) | Chalco, Nanshan | Closest commercial equivalent based on low-Cu compositions. |

Korea (KS) | ALDC1 | Poongsan ALDC1 | Harmonized with JIS ADC1 chemistry. |

Design Purpose

ADC1 was formulated to provide a clean, corrosion-resistant aluminum solution for highly cosmetic consumer products and precision electronic components. With minimal copper and low impurity levels, it generates superior anodizing quality, high reflectivity, and a smooth metallic appearance. Its relatively low mechanical strength compared with ADC12 is intentional—ensuring excellent ductility, reduced cracking tendencies, and stable filling for thin-wall designs. The alloy was also designed to provide excellent electrical insulation and thermal uniformity, making it suitable for communication device enclosures and lightweight mechanical modules that require consistent dimensional stability.

Chemical Composition

Element | Silicon (Si) | Copper (Cu) | Magnesium (Mg) | Iron (Fe) | Mn | Zinc (Zn) | Titanium (Ti) | Aluminum (Al) |

Composition (%) | 0.2–0.6 | ≤0.05 | ≤0.05 | ≤0.70 | ≤0.05 | ≤0.10 | ≤0.05 | Balance (high-purity) |

Physical Properties

Property | Density | Melting Range | Thermal Conductivity | Electrical Conductivity | Thermal Expansion |

Value | ~2.70 g/cm³ | ~645–660 °C | ~210–230 W/m·K | ~55–60% IACS | ~23–24 µm/m·°C |

Mechanical Properties

Property | Tensile Strength | Yield Strength | Elongation | Hardness | Fatigue Strength |

Value | ~70–110 MPa | ~40–70 MPa | ~15–30% | ~35–45 HB | Low–moderate |

Key Material Characteristics

Excellent corrosion resistance due to low-copper composition.

Outstanding anodizing appearance with bright, uniform metallic finishes.

High electrical and thermal conductivity suitable for electronic housings.

Superior ductility for thin-wall, crack-sensitive designs.

Low strength but excellent dimensional stability for cosmetic components.

Very smooth as-cast surfaces for premium visual applications.

Minimal porosity when cast under controlled conditions.

Environmentally stable alloy with minimal stress-corrosion tendency.

Manufacturability And Post Process

High-pressure die casting (HPDC): Best suited for producing thin-wall housings and cosmetic shells. ADC1 fills uniformly due to its low-Si content, enabling clean edges and low defect rates.

Gravity casting: Used for small mechanical brackets requiring improved structural integrity.

Sand casting: Limited use; primarily selected for larger prototypes or thick parts that require corrosion resistance.

Post-machining: Processes such as drilling, milling, and threading achieve an accuracy of ±0.03–0.06 mm via post-machining. Soft chip formation improves tool life.

Tumbling and polishing: Tumbling enhances surface quality prior to coating.

Assembly integration: ADC1 supports press-fit and fastener assembly, often used in multi-component electronic modules using assembling.

Quality inspection: Cosmetic-grade parts undergo visual inspection, CMM checks, and porosity mapping using Neway’s inspection equipment.

Suitable Surface Treatment

Anodizing: Anodizing performs exceptionally well—bright, uniform colors with minimal grain shadows.

Clear anodizing: Ideal for premium electronics and visual components.

Powder coating: Powder coating adds durable scratch-resistant protection.

Liquid painting: Painting achieves smooth gloss or matte finishes.

Bead-blasting: Pre-treatment via sand-blasting provides texture consistency.

Laser marking: High contrast and minimal heat-affected zones for branding codes.

Conversion coating: Enhances corrosion resistance and paint adhesion on sensitive components.

Common Industries and Applications

Communication device housings and antenna mounts.

Consumer electronics shells and decorative components.

Optical equipment structures requiring thermal uniformity.

Small brackets, covers, and light mechanical components.

Marine and outdoor hardware due to corrosion resistance.

Precision electronic modules where conductivity matters.

When to Choose This Material

When excellent corrosion resistance and cosmetic appearance are required.

When anodizing quality must be exceptionally high.

For thin-wall, low-stress, visually critical housings.

When electrical or thermal conductivity is beneficial.

When low defect rates and uniform filling are required in die casting.

For soft-machining, easy-to-finish aluminum designs.

When dimensional stability outweighs the need for high strength.