Leaded Bronze (Ounce Metal) C83600

Material Introduction

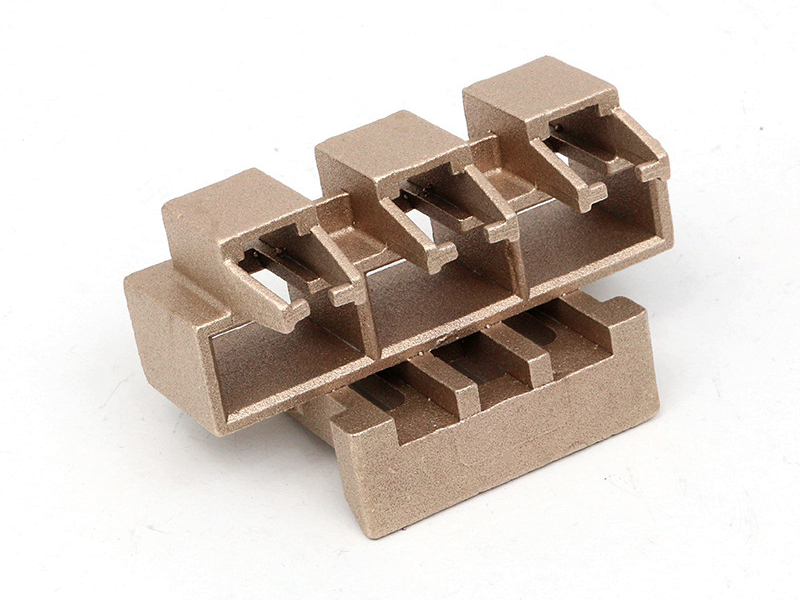

Leaded Bronze C83600, traditionally known as "Ounce Metal" due to its historic density of one pound per cubic inch, is a premium cast copper alloy renowned for its exceptional combination of corrosion resistance, machinability, and pressure tightness. As one of the most widely used leaded tin bronzes, this alloy provides reliable performance across various applications, including plumbing, marine, and general industrial sectors. The strategic addition of tin provides excellent corrosion resistance, while the lead content significantly enhances machinability and ensures leak-proof castings by filling micro-porosity. When processed through Neway's advanced copper die casting capabilities and precision tool and die making systems, C83600 consistently produces high-integrity components with excellent surface finish and dimensional stability, making it the industry standard for quality bronze castings.

Alternative Material Options

For applications requiring higher strength and wear resistance, Aluminum Bronze C95400 offers superior mechanical properties. When superior machinability is the primary concern for high-volume production, Leaded Free-Cutting Brass C48500 provides unparalleled cutting performance. For more cost-effective applications where the red color and some corrosion resistance are still desired, Semi-Red Brass C84400 serves as an economical alternative. In applications requiring higher tin content for improved corrosion resistance in specific environments, Tin Bronze C90500 offers a premium solution. For marine applications demanding exceptional resistance to seawater corrosion, Aluminum Bronze C95400 or Silicon Bronze C65500 may be considered. When lead-free compliance is mandatory, Silicon Brass C87850 provides a suitable alternative.

International Equivalent / Comparable Grade

Country/Region | Equivalent / Comparable Grade | Specific Commercial Brands | Notes |

USA (ASTM/UNS) | C83600 (SAE 40) | Ampco C83600, Concast Ounce Metal, Aviva Metals C83600 | Standard UNS designation for leaded red bronze (85-5-5-5). |

Europe (EN) | CuPb5Sn5Zn5 (CC491K) | KME CC491K, Wieland CuPb5Sn5Zn5, Luvata CC491K | European leaded bronze equivalent with similar composition. |

Japan (JIS) | BsBM2 (CAC402) | JX Nippon BsBM2, Tsuchiya CAC402 | Japanese cast bronze grade matching C83600 characteristics. |

Germany (DIN) | G-CuPb5Sn5Zn5 | Diehl Metall G-CuPb5Sn5Zn5, Aurubis G-CuPb5Sn5Zn5 | German specification for leaded tin bronze castings. |

China (GB/T) | ZCuSn5Pb5Zn5 | Ningbo ZCuSn5Pb5Zn5, Zhongse Leaded Bronze | Chinese leaded tin bronze equivalent to C83600. |

International (ISO) | CuPb5Sn5Zn5 | Various ISO-certified bronze foundries | International standard for leaded tin bronze alloys. |

UK (BS) | LG2 (BS 1400) | British Standard LG2 Leaded Gunmetal | UK specification closely matching C83600 composition. |

France (NF) | CuPb5Sn5Zn5 (A55D) | Tréfimétaux A55D, Fonderie de France CuPb5Sn5Zn5 | French leaded bronze equivalent with same element ratios. |

Design Purpose

Leaded Bronze C83600 was specifically engineered to provide an optimal balance of castability, corrosion resistance, and machinability for general-purpose bronze applications. The alloy's formulation addresses the critical need for pressure-tight castings in plumbing and hydraulic applications while maintaining the excellent corrosion resistance characteristic of high-tin bronzes. The strategic inclusion of lead (4-6%) serves multiple purposes: it dramatically improves machinability by promoting chip breakage and reducing tool wear, enhances pressure tightness by filling micro-shrinkage porosity, and improves the alloy's anti-seizing and bearing properties. This sophisticated balance makes C83600 particularly well-suited for components that require extensive post-casting machining while maintaining leak-proof integrity under pressure, establishing it as the benchmark alloy for high-quality bronze valve bodies, pump casings, and plumbing fittings.

Chemical Composition

Element | Copper (Cu) | Tin (Sn) | Lead (Pb) | Zinc (Zn) | Iron (Fe) | Other Elements |

Composition (%) | 84.0-86.0 | 4.3-6.0 | 4.0-6.0 | 4.0-6.0 | ≤0.30 | ≤0.50 total |

Physical Properties

Property | Density | Melting Range | Thermal Conductivity | Electrical Conductivity | Thermal Expansion |

Value | 8.94 g/cm³ | 900-1000°C | 58 W/m·K | 14% IACS | 18.7 μm/m·°C |

Mechanical Properties

Property | Tensile Strength | Yield Strength (0.5%) | Elongation | Hardness | Impact Strength |

Value | 240 MPa | 120 MPa | 25% | 60 HB | 20 J |

Key Material Characteristics

Excellent corrosion resistance in freshwater, seawater, and industrial atmospheres

Superior pressure tightness ideal for valves, pumps, and plumbing components

Outstanding machinability with 90% rating compared to free-cutting brass

Good castability with excellent fluidity and minimal shrinkage defects

Excellent bearing properties and anti-galling characteristics

Good wear resistance for moving components and valve seats

Reliable performance across wide temperature ranges

Attractive traditional bronze appearance for architectural applications

Good weldability and repair capabilities when needed

Historically proven reliability in demanding applications

Manufacturability And Post Process

Copper Die Casting: Excellent fluidity enables production of complex, high-integrity castings with fine detail

Sand Casting and Centrifugal Casting: Ideal for larger components and pressure-retaining parts

Post Machining: Superior machinability enables high-speed operations with excellent surface finish

Drilling and Tapping: Produces clean, precise threads with minimal tool wear and excellent chip formation

Tumbling: Effective for deburring and achieving uniform surface radiusing

Sand Blasting: Creates consistent surface textures for aesthetic or functional purposes

Grinding and Polishing: Achieves high-quality surface finishes from functional to decorative

Suitable Surface Treatment

Clear Lacquering: Preserves natural bronze appearance while preventing oxidation and tarnishing

Chemical Patina: Creates antique or statuary finishes for architectural applications

Electroplating: Compatible with nickel, chrome, and special finishes for decorative hardware

Passivation Treatments: Enhance tarnish resistance while maintaining the alloy's natural color

Polishing and Buffing: Achieves high-luster finishes for premium decorative applications

Oxide Sealing: Chemical treatments that stabilize the surface and enhance corrosion resistance

Common Industries and Applications

Plumbing fixtures: valve bodies, faucet components, and pipe fittings

Marine hardware: seawater system components, fittings, and underwater applications

Industrial valves: gate valves, globe valves, ball valves, and pressure control valves

Pump components: casings, impellers, and wear rings for water and chemical service

Architectural hardware: decorative door hardware, railings, and building fixtures

General engineering: bearings, bushings, gears, and mechanical components

Electrical components: conduit fittings, connector bodies, and electrical hardware

When to Choose This Material

Pressure-containing applications: Superior pressure tightness ensures leak-proof performance in valves and fittings

Components requiring extensive machining: Excellent machinability significantly reduces manufacturing costs and time

Marine and corrosive environments: Proven corrosion resistance in freshwater, seawater, and chemical exposure

Bearing and wear applications: Good anti-galling properties and wear resistance for moving components

Architectural applications: Traditional bronze appearance with excellent corrosion resistance

General-purpose bronze castings: Reliable, well-understood material with predictable performance

Complex geometry components: Excellent castability enables production of intricate shapes and thin walls