Inconel 718

Introduction to Inconel 718

Inconel 718 is a precipitation-hardening nickel-chromium alloy designed for exceptional strength and corrosion resistance in extreme temperature and pressure conditions. Its superior weldability, thermal stability, and fatigue resistance make it ideal for aerospace, energy, and high-performance tooling applications.

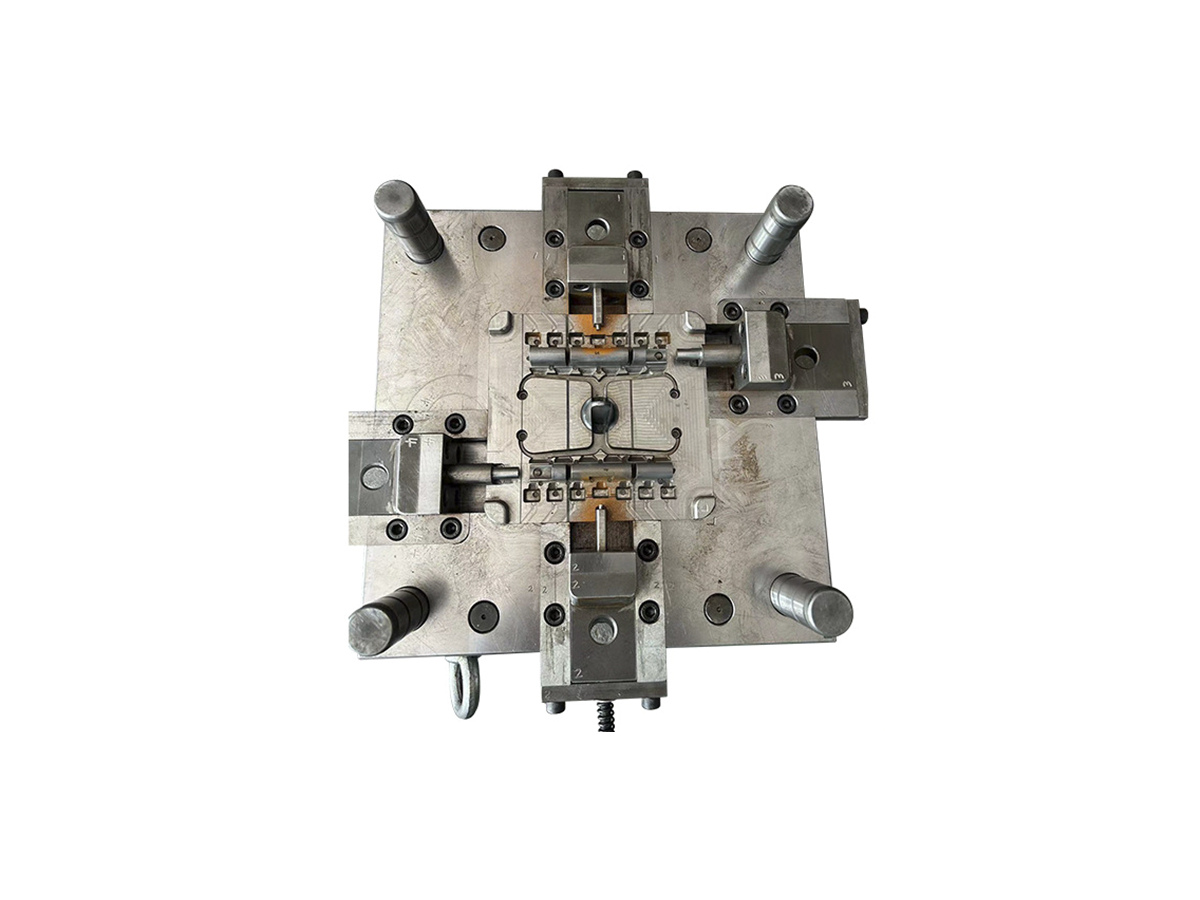

At Neway Die Casting, Inconel 718 is a key tooling alloy used in molds and dies subjected to cyclic thermal shock and wear, especially for high-pressure aluminum and zinc die casting.

Inconel 718 Chemical Composition (per AMS 5662/5663)

Element | Weight % | Function |

|---|---|---|

Nickel (Ni) | 50–55 | Base alloy element, corrosion resistance |

Chromium (Cr) | 17–21 | Oxidation resistance, strength retention |

Iron (Fe) | Balance | Matrix component |

Niobium + Tantalum (Nb+Ta) | 4.75–5.5 | Strength through precipitation hardening |

Molybdenum (Mo) | 2.8–3.3 | Enhances high-temperature strength |

Titanium (Ti) | 0.65–1.15 | Grain control and strength |

Aluminum (Al) | 0.2–0.8 | γ' strengthening phase |

Cobalt (Co), Manganese (Mn), Silicon (Si), Carbon (C), Boron (B), Copper (Cu) | Trace | Controlled for balance, cleanliness, and weldability |

Physical Properties of Inconel 718

Property | Value & Unit |

|---|---|

Density | 8.19 g/cm³ |

Melting Range | 1260–1336 °C |

Specific Heat | 435 J/kg·K |

Thermal Conductivity | 11.4 W/m·K |

Electrical Resistivity | 1.29 µΩ·m |

Coefficient of Thermal Expansion | 13.0 µm/m·°C (20–1000°C) |

Inconel 718 offers thermal stability across a wide temperature range, critical for cyclic tooling and aerospace parts.

Mechanical Properties (Solution Annealed + Aged)

Property | Value & Unit |

|---|---|

Ultimate Tensile Strength | 1240 MPa |

Yield Strength (0.2% offset) | 1030 MPa |

Elongation | 12–20 % |

Hardness | ~331 HB (44 HRC) |

Fatigue Strength (10⁷ cycles) | ~480 MPa |

Modulus of Elasticity | ~207 GPa |

These values remain stable up to 650 °C, complying with standards such as AMS 5663 and ASTM B637.

Casting and Tooling Characteristics

Inconel 718 is not traditionally used for complex part casting due to its poor fluidity and high melting point, but it is ideal for:

Die casting core inserts and dies exposed to extreme thermal cycling

Tooling requiring long life under high shot pressures (e.g., >1000 bar)

Aerospace and energy components requiring fatigue and creep resistance

Neway’s tool and die making capabilities include precision machining, stress-relief heat treatment, and multi-axis CNC for Inconel 718 tooling components.

Common Applications

Inconel 718 is commonly specified in the following demanding applications:

Aerospace: turbine discs, engine components, fuel nozzles

Automotive: turbocharger impellers, high-performance valve seats

Power generation: nuclear reactor parts, boiler components

Die casting: high-cavity die inserts, cores for long-cycle production

Mold design for corrosive and thermal-intensive die casting operations

Machining Challenges and Solutions

Due to its work hardening and strength retention properties, Inconel 718 presents several machining difficulties:

Generates high cutting temperatures and tool wear

Prone to surface hardening under inadequate feeds

Requires rigid setups and optimal cutting parameters

Neway addresses these challenges with:

Use of ceramic and coated carbide tooling (e.g., TiAlN, AlCrN)

Low-speed, high-feed strategies with aggressive coolant systems

Pre-machining heat treatment for stress relief

In-process inspection for tolerances within ±0.01 mm

Surface Treatment Compatibility

Though already oxidation and corrosion resistant, Inconel 718 can be further enhanced by:

Nitriding for surface hardness

Shot peening for fatigue life improvement

Specialized coatings (e.g., PVD) in high-friction environments

These are often applied in molds requiring thermal resistance and wear control.

FAQs

What’s the maximum service temperature for Inconel 718 die inserts?

Can Inconel 718 be EDM machined for complex mold geometries?

How does Inconel 718 compare to H13 in die life performance?

What are the recommended cutting speeds for CNC machining Inconel 718?

Is Inconel 718 suitable for large-volume die cast tooling?