Tool Steel S7

Introduction to Tool Steel S7

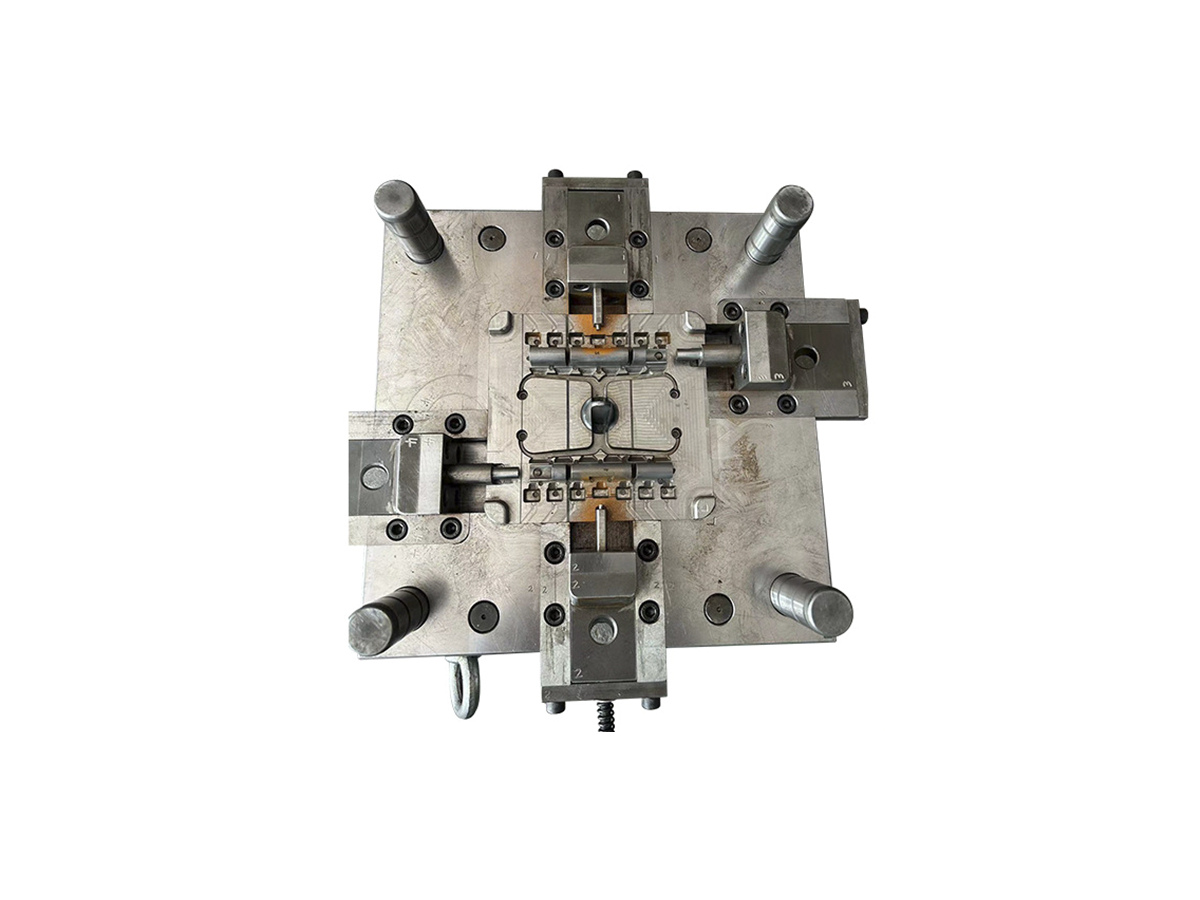

Tool Steel S7 is a versatile air-hardening tool steel formulated explicitly for superior impact toughness, moderate wear resistance, and dimensional stability under rapid temperature shifts. As a medium-alloyed steel, S7 is widely used in aluminum and zinc die casting tooling, hot trimming dies, and heavy-duty inserts subject to repeated impact.

At Neway Die Casting, S7 is selected for tooling components where high energy absorption, crack resistance, and resistance to thermal shock are essential.

Tool Steel S7 Chemical Composition (Typical, per ASTM A681)

Element | Weight % | Function |

|---|---|---|

Chromium (Cr) | 3.0–3.5 | Improves hardenability and corrosion resistance |

Molybdenum (Mo) | 1.3–1.8 | Strengthens steel at elevated temperatures |

Vanadium (V) | 0.2–0.3 | Promotes wear resistance and grain refinement |

Carbon (C) | 0.45–0.55 | Contributes to hardness and strength |

Manganese (Mn) | 0.2–0.8 | Enhances toughness and hardenability |

Silicon (Si) | 0.2–1.0 | Improves temper resistance |

Iron (Fe) | Balance | Base matrix metal |

This balanced alloy system gives S7 its signature shock resistance while maintaining sufficient edge retention for tooling durability.

Physical Properties of Tool Steel S7

Property | Value & Unit |

|---|---|

Density | ~7.8 g/cm³ |

Thermal Conductivity | 24–27 W/m·K |

Coefficient of Thermal Expansion | 11.3–12.1 µm/m·°C |

Specific Heat Capacity | ~460 J/kg·K |

Electrical Resistivity | ~0.65 µΩ·m |

Hardenability Range | Up to 50 HRC at 100 mm section |

Air-hardening minimizes warping during quenching, making it ideal for complex or tight-tolerance mold geometries.

Mechanical Properties (Heat Treated to 50–54 HRC)

Property | Typical Value & Unit |

|---|---|

Tensile Strength | 1650–1900 MPa |

Yield Strength | ~1400 MPa |

Impact Toughness (Charpy V-notch) | >30–50 J |

Hardness | 50–54 HRC |

Elongation | 8–10 % |

Modulus of Elasticity | ~210 GPa |

S7 maintains excellent toughness without compromising dimensional control or surface quality under cyclic mechanical loading.

Die Casting Performance Characteristics

S7 is particularly well-suited for:

High-shock tooling such as trim dies, ejector plates, and gate inserts

High-velocity zinc or aluminum shot impact zones

Tooling applications where thermal cycling and mechanical fatigue converge

Areas prone to chipping or cracking in complex multi-slide molds

Its thermal stability ensures minimal distortion during prolonged use, and the steel's resistance to cracking significantly reduces tool downtime.

Common Applications

Tool Steel S7 finds usage in:

Die casting trim dies for flash removal

Core pins and gate inserts for aluminum and zinc parts

Plastic injection mold components requiring high toughness

Shear blades, punches, and forming dies

Mass production tooling involving high-cycle impact environments

Machining Challenges and Solutions

S7, though tough, is readily machinable in the annealed condition but becomes challenging post-hardening:

Requires rigid fixturing due to high toughness

Machining in the hardened state is limited to grinding and EDM

Use of high-speed steel or carbide tools is recommended during rough machining

At Neway, precision CNC machining and optimized heat treatment workflows are integrated to ensure:

Tolerance retention within ±0.01 mm

Pre-hardening stress relief

Surface finishes down to Ra 0.8 µm

Surface Treatment Compatibility

Tool Steel S7 accepts various hardening and wear-resistant coatings to enhance die performance:

Nitriding for surface hardness and galling resistance

PVD coatings (e.g., TiN, TiCN) for ejection areas

Cryogenic treatment to improve microstructural homogeneity

These treatments enable longer service intervals even under high-temperature, abrasive conditions.

FAQs

How does S7 compare to H13 in terms of impact resistance and toughness?

Can S7 be used for die casting and trimming operations in the same tool?

What is the best heat treatment cycle for achieving 52 HRC in S7 dies?

Is S7 suitable for fine-feature EDM components?

What are the expected failure modes in S7 tooling under thermal fatigue?