ZDC2

Material Introduction

ZDC2 is a premium zinc alloy for high-performance zinc die casting, engineered to deliver outstanding strength, hardness, and wear resistance. As the JIS cast designation aligns with the Zamak 2 family, ZDC2 incorporates an elevated copper content compared to ZDC1/Zamak 5, significantly enhancing its load-bearing capability and resistance to fatigue and creep. This makes it especially suitable for small to medium-sized components that are subjected to continuous stress, high-frequency actuation, or demanding contact conditions in service. ZDC2 combines excellent fluidity with robust feeding behavior, enabling it to reproduce detailed geometries, thin walls, and complex functional features with reliable dimensional repeatability. When processed through Neway’s optimized hot-chamber metal casting platforms and supported by precision tool and die making, ZDC2 enables robust, long-life castings that maintain performance in challenging mechanical and thermal environments.

Alternative Material Options

When certain design priorities outweigh the advantages of ZDC2, several alternatives can be considered. For general-purpose applications where ductility and dimensional stability are more important than maximum strength, Zamak 3 is often preferred as a cost-effective, widely available standard zinc alloy. If a balance of increased strength with good castability is required, Zamak 5 or ZDC1 (where specified) can offer better formability and finishing flexibility. For extremely thin-wall or micro-precision parts, Zamak 7 provides higher fluidity and lower impurity levels. In applications that require a luxurious appearance or superior corrosion resistance, copper-based solutions such as Brass 380 or broader copper-brass alloys are excellent candidates. For lightweight thermal management housings, aluminum alloys such as A380 and A383/ADC12 can be selected from Neway’s aluminum die casting portfolio.

International Equivalent / Comparable Grade

Country/Region | Equivalent / Comparable Grade | Specific Commercial / Standard Names | Notes |

Japan (JIS H 5301) | ZDC2 | Standard Japanese cast zinc alloy | Cast designation corresponding to high-copper zinc die casting alloy. |

USA (ASTM B86/B240) | Alloy 2 / Zamak 2 | ZnAl4Cu3, Alloy 2 | High-strength zinc alloy with elevated copper for better creep resistance. |

Europe (EN 1774 / EN 12844) | ZL0430 / ZP0430 | ZL0430 ZnAl4Cu3 | European ingot and cast designations for Zamak 2-type alloys. |

China (GB) | ZL2-type | ZnAl4Cu3 family | Chinese practice commonly references Zn–Al–Cu high-strength zinc alloys. |

Germany (DIN) | Z430 | ZnAl4Cu3 | A German alloy similar to Zamak 2, but with increased copper content. |

International (ISO) | ZnAl4Cu3 | Generic Zn–4Al–3Cu zinc casting alloy | International composition family commonly aligned with ZDC2/Zamak 2. |

Design Purpose

ZDC2 was specifically designed for applications where zinc die castings are exposed to sustained mechanical loads, long-term stress, or high-frequency mechanical cycling. By significantly increasing the copper content compared with more conventional zinc alloys, ZDC2 offers higher strength, hardness, and creep resistance, enabling smaller cross-sections and more compact designs without sacrificing service life. The alloy targets demanding mechanisms such as locking systems, power tools, gears, levers, and high-load joints that must maintain dimensional integrity under repeated actuation. Its design intent is to provide an economical alternative to brass or steel for many precision components, while still benefiting from the fast-cycle efficiencies and excellent surface quality inherent to zinc die casting. At Neway, ZDC2 is deployed where reliability, mechanical robustness, and premium finishing potential must converge in a single, production-ready material.

Chemical Composition

Element | Zinc (Zn) | Aluminum (Al) | Copper (Cu) | Magnesium (Mg) | Iron (Fe) | Lead/Cadmium/Tin |

Composition (%) | Balance | 3.8–4.3 | 2.5–3.0 | 0.02–0.06 | ≤0.075 | Trace (typically <0.003 each) |

Physical Properties

Property | Density | Melting / Solidification Range | Thermal Conductivity | Electrical Conductivity | Thermal Expansion |

Value | ~6.7 g/cm³ | ~380–390°C | ~100–105 W/m·K | ~24–26% IACS | ~27–28 µm/m·°C |

Mechanical Properties

Property | Tensile Strength (UTS) | Yield Strength (0.2% offset) | Elongation | Hardness | Fatigue / Impact Performance |

Value | ~350–380 MPa | ~260–300 MPa | ~1–3% | ~95–110 HB | High fatigue and wear resistance in service |

Key Material Characteristics

Very high strength and hardness compared with standard zinc alloys such as Zamak 3, enabling reduced wall thickness and compact structural solutions.

Excellent creep resistance and dimensional stability under long-term mechanical loading, making it suitable for stressed components in locking systems and power tools.

Reliable castability in hot-chamber zinc die casting processes, with good mold filling behavior for complex cavities and fine features.

Excellent wear resistance and contact fatigue performance, making it ideal for gears, cams, levers, and sliding or rotating interfaces.

High-quality as-cast surface finish that readily accepts cosmetic coatings, minimizing the extent of post-machining on non-critical surfaces.

Compatible with a range of finishes provided through Neway’s integrated post process for die castings, including painting, powder coating, and plating systems.

Excellent capability for embedding inserts and forming detailed bosses, threads, and functional geometries in a single casting operation.

Better load-bearing performance than many aluminum alloys of similar section, while still benefiting from short cycle times and efficient tool utilization.

Excellent corrosion resistance in indoor and moderately aggressive environments; can be easily enhanced through the application of conversion coatings and organic finishes.

Stable performance in precision assemblies where multiple ZDC2 parts or mixed-material components must maintain alignment throughout the product life.

Manufacturability And Post Process

Zinc die casting: ZDC2 is primarily processed in hot-chamber machines, taking advantage of rapid cycling, excellent shot-to-shot repeatability, and efficient alloy handling for high-volume programs.

Tooling engineering: Optimized runner, gate, and overflow designs in Neway’s tool and die systems help manage higher solidification stresses, reducing the risk of hot cracking or dimensional distortion.

Insert casting and overmolding of metallic inserts: ZDC2 flows well around steel or brass inserts, allowing for the integration of threads, bearing surfaces, contact pads, or structural reinforcements in a single casting step.

Secondary post machining: Milling, boring, drilling, and reaming operations can achieve tight tolerances and fine surface finishes on sealing or alignment-critical areas.

Drilling and tapping: ZDC2 forms sound, repeatable threads with good pull-out strength; process parameters can be tuned to balance tool life and surface integrity.

Deburring and tumbling: Mechanical finishing processes efficiently remove micro-burrs and sharp edges, improving ergonomics and preparing the surface for subsequent coating.

Surface preparation by sandblasting creates consistent textures, hides minor defects, and provides a key for high-adhesion coatings.

Dimensional verification and inspection: High stability allows robust in-line gauging; when required, Neway can support advanced die castings inspection for safety-critical parts.

Process integration: ZDC2 components can be transferred directly into in-house assembling lines, allowing Neway to deliver fully built sub-systems ready for OEM installation.

Suitable Surface Treatment

Powder coating: Provides tough, abrasion-resistant coatings with excellent coverage and color uniformity, widely used for industrial and consumer hardware.

Liquid painting: Enables a wide range of colors, gloss levels, and special effects, ideal for visible housing parts and branded products.

Sand blasting: Produces controlled matte or satin textures that enhance perceived quality and help mask minor cosmetic imperfections before coating.

Tumbling: Improves hand-feel on knobs, handles, and levers while rounding sharp edges that could otherwise damage coatings or gaskets.

Electroplating (nickel, chrome, duplex decorative stacks): Often applied to ZDC2 for premium appearance, improved wear performance, and enhanced corrosion resistance in demanding environments.

Chemical conversion coatings: Thin chromate or trivalent passivation layers act as both corrosion protection and primer for subsequent organic coatings.

E-coating: Offers uniform film thickness and high throwing power, protecting complex geometries and internal cavities from corrosion.

Laser marking: Enables durable, high-contrast part identification, traceability codes, and branding on coated or uncoated ZDC2 surfaces.

Common Industries and Applications

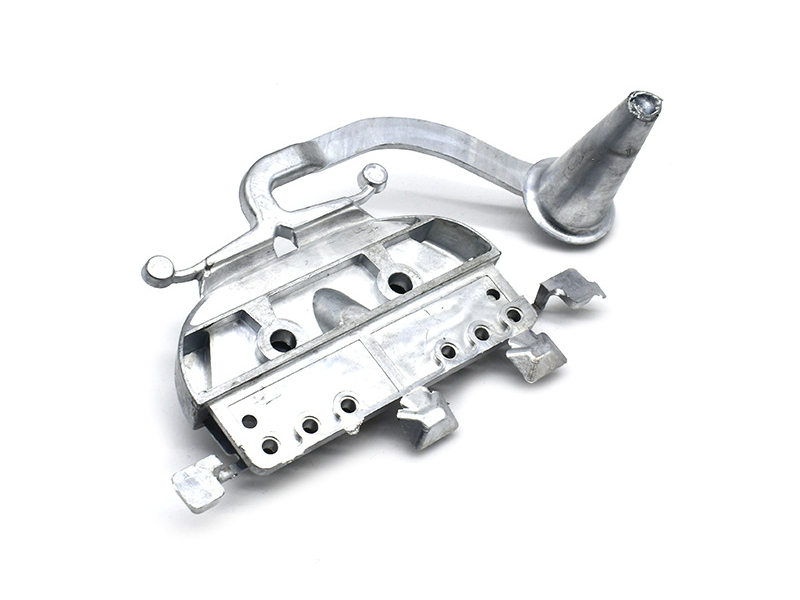

Locking systems, latches, and access control components where high-strength, wear-resistant mechanisms are required, similar to the Dirak lock system casting supply projects.

Power tool hardware, trigger mechanisms, and structural brackets, aligned with Neway’s experience in Bosch power tools castings and assembling.

Precision mechanical components and small gears for industrial equipment, actuators, and automation systems requiring long-term reliability.

Consumer product hardware and decorative fittings require high perceived quality, mechanical robustness, and refined surfaces.

Electrical and electronic hardware, including robust switch parts and structural support elements within enclosures.

Automotive interior and under-dash components that combine functional loading with restricted packaging space.

When to Choose This Material

When your design requires maximum strength and hardness from a zinc die casting alloy, especially under prolonged stress, elevated temperatures, or high-cycle loads.

When components such as locks, gears, levers, and key structural brackets must maintain dimensional accuracy and functional integrity throughout a long service life.

When you want to replace machined steel or brass parts with a die-cast solution to reduce cost and part weight while maintaining high performance.

When you need high-quality, finish-ready surfaces that can accept plating, painting, or powder coating without extensive surface grinding.

When program economics demand fast cycle times, long tool life, and integrated features that minimize secondary operations within Neway’s post process chain.

When mixed-material assemblies would benefit from cast-in inserts, precise threads, and multi-level geometry produced in a single shot.

When your product requires both mechanical robustness and a premium feel, place ZDC2 at the intersection of performance and aesthetics.

When long-term stability and fatigue resistance are more critical than maximum ductility, and design allowances can accommodate the alloy’s higher hardness.