Precision CNC Machining for Small-Run, Custom, and Unique Components

Introduction

Modern industries increasingly demand flexibility, speed, and precision in part manufacturing, especially for small-run, custom, and unique components. Precision CNC machining is ideally suited to meet these demands. Whether you're creating aerospace brackets in quantities of ten or intricate medical enclosures with ±0.005 mm tolerances, CNC technology ensures consistency, complexity, and customization at scale.

At Neway, our CNC machining services are designed to deliver high-accuracy, short-run metals and plastics components optimized for fast delivery and functional excellence.

Why CNC Machining is Ideal for Small-Run Custom Parts

Unlike mass production methods that require expensive tooling and long setup times, CNC machining provides:

Digital repeatability: CAD/CAM-driven processes ensure every unit meets design specifications precisely.

Quick setup for low volume: Ideal for 1–500 units production runs.

No need for hard tooling: Designs can be changed rapidly without retooling, supporting iteration and customization.

High Precision Capabilities

Precision CNC machining can achieve:

Tolerances: As tight as ±0.005 mm

Surface finishes: As smooth as Ra 0.8 µm

Hole location accuracy: Within ±0.01 mm, critical for assemblies

This level of precision is essential for components in:

Aerospace (brackets, housings, turbine accessories)

Medical devices (implants, enclosures, diagnostic equipment)

Industrial automation (custom jigs, fixtures, and gears)

Electronics (heat sinks, connectors, housing frames)

Material Versatility

Neway machines a wide range of materials to meet application-specific needs, including:

Metals

Stainless steel: 304, 316 for corrosion-resistant medical and marine parts

Copper alloys: C18200, Brass 360 for electrical and plumbing systems

Tool steels: D2, H13 for durable dies and forming components

Plastics

POM (Delrin): Low-friction, high-stiffness parts

PEEK: High-performance, chemically resistant components

Nylon, ABS, PC: Cost-effective engineering thermoplastics for custom housings and prototypes

CNC Services Offered

Our capabilities include:

Process | Precision Range | Typical Use Case |

|---|---|---|

3-Axis Milling | ±0.01 mm | Flat or prismatic parts |

5-Axis Milling | ±0.005 mm | Complex geometries and undercuts |

CNC Turning | ±0.01 mm | Cylindrical parts, shafts, bushings |

CNC Drilling | Positional accuracy ±0.02 mm | Deep hole drilling, tapping, threading |

CNC Boring | Surface roundness ±0.005 mm | High-precision internal diameters |

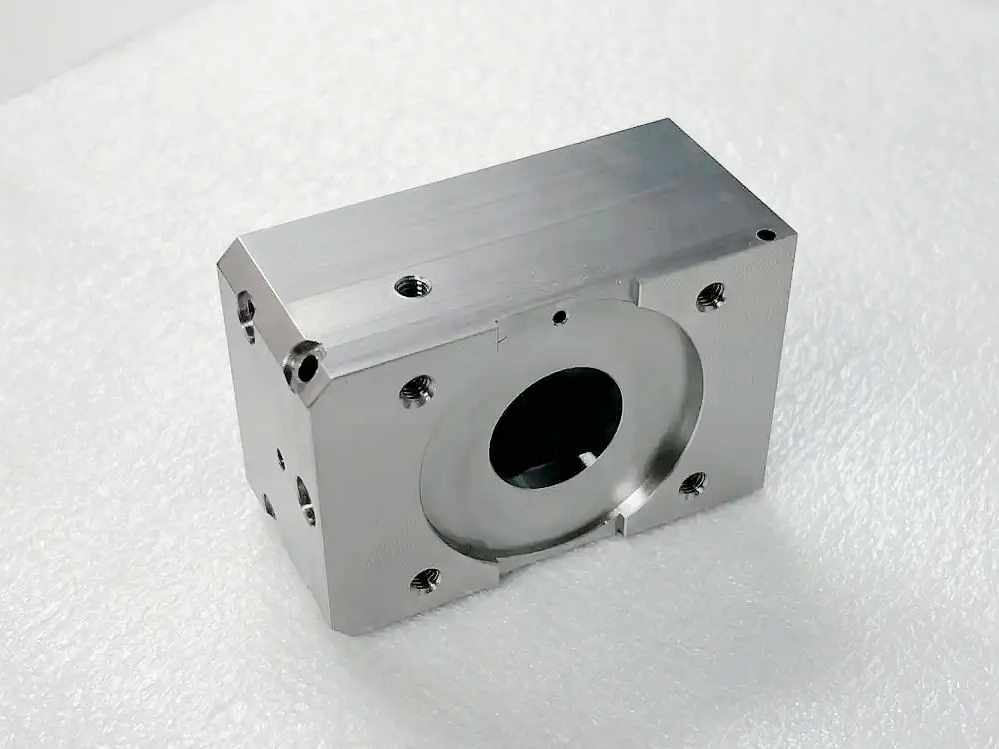

Application Example: Custom Sensor Housing for Industrial Automation

A client required 150 precision-machined housings in AC4C aluminum for a high-vibration industrial environment. We provided:

±0.01 mm tolerance on bearing seats

Custom M4 and M6 threaded holes

Powder coating for enhanced wear resistance

The components were delivered within 10 business days and passed functional validation without revision.

Surface Finishing and Assembly Integration

Neway offers post-processing options for custom components, including:

Anodizing for corrosion protection and color coding

Sand blasting and tumbling for matte or uniform texture

Tight-tolerance post-machining and sub-assembly of mating parts

This ensures a complete, ready-to-use solution for even the most demanding applications.

Benefits of Small-Run Precision CNC Machining

Advantage | Description |

|---|---|

Flexibility | Modify or personalize part features without tooling changes |

Speed | Lead times from 5–12 business days depending on complexity |

Quality Assurance | In-house CMM inspection with inspection reports as required |

Cost-Efficiency | Ideal for bridge production, pilots, and limited product releases |

Conclusion

Small-run, custom, and unique components demand manufacturing processes that offer flexibility without sacrificing precision. CNC machining meets these demands with unmatched control, repeatability, and material versatility.

At Neway, our team delivers production-ready CNC-machined parts with industry-grade tolerances and professional finishing—even for one-off or short-run jobs. Whether you're developing prototypes, fulfilling specialty orders, or scaling to low-volume production, we’re your partner for precision.

FAQs

What is the typical lead time for small-run CNC machining orders?

Can CNC machining support production in final-use materials like aluminum or stainless steel?

What level of precision can be achieved in custom CNC parts?

Is post-processing like anodizing or powder coating available for short-run jobs?

How does Neway ensure quality in small-batch CNC production?